- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Stainless Steel Floor Grating Durable & Corrosion-Resistant Solutions

- Overview of Stainless Steel Floor Grating

- Technical Superiority & Performance Metrics

- Comparative Analysis: Leading Manufacturers

- Customization Options for Varied Needs

- Industry-Specific Application Case Studies

- Installation Best Practices

- Why Stainless Floor Grates Are Future-Proof

(stainless steel floor grating)

Stainless Steel Floor Grating: The Industrial Standard

Stainless steel floor grating has become a cornerstone in architectural and industrial design due to its unmatched durability. With a global market growth rate of 6.8% CAGR (2023-2030), these grates are preferred in corrosive environments, heavy-traffic zones, and hygienic facilities. Industries such as wastewater treatment, offshore platforms, and food processing rely on stainless floor grates for their 50+ year lifespan, reducing replacement costs by 73% compared to carbon steel alternatives.

Technical Superiority & Performance Metrics

Grade 316 stainless steel grates dominate critical applications with:

- Load capacity: 1,500 lbs/ft² (vs. 900 lbs/ft² for aluminum)

- Corrosion resistance: 10,000+ hours in salt spray tests

- Slip resistance: 0.68 coefficient (wet conditions)

Electropolishing and serrated surface treatments enhance safety and longevity, particularly in chemical plants where pH resistance from 1 to 13 is mandatory.

Manufacturer Comparison: Key Specifications

| Manufacturer | Material Grade | Max Load (lbs/ft²) | Corrosion Rating | Warranty |

|---|---|---|---|---|

| Supplier A | 304/316 | 1,200 | ASTM A967 | 20 years |

| Supplier B | 316L | 1,800 | NACE MR0175 | 35 years |

| Supplier C | Duplex 2205 | 2,500 | ISO 15156 | Lifetime |

Tailored Solutions for Complex Requirements

Custom stainless floor grating configurations address:

- Non-standard panel dimensions (up to 8m x 3m)

- Specialized mesh patterns (30° / 45° / 60° bends)

- Integrated drainage slopes (0.5° - 5° precision)

Laser-cut openings maintain ±0.2mm tolerances for pharmaceutical cleanrooms requiring 99.97% particulate containment.

Real-World Implementation Success Stories

Case 1: Oil refinery walkways reduced maintenance frequency from quarterly to biennial cycles after installing 316SS grates with 2.5mm serrated surfaces.

Case 2: A European brewery achieved 34% energy savings through optimized grating layouts that enhanced steam dissipation in fermentation areas.

Optimized Installation Methodology

Proper installation of stainless floor grates requires:

- Anchoring systems rated for 3x expected load

- Thermal expansion gaps (3mm per meter)

- Galvanic isolation from dissimilar metals

Field measurements show incorrect installations cause 82% of premature failures, emphasizing adherence to EN ISO 14122-4 standards.

Stainless Floor Grates: Sustainable Infrastructure Choice

With 92% recyclability and zero maintenance chemical requirements, stainless steel floor grating

supports circular economy goals. Recent advancements in nano-coated surfaces (120% improved abrasion resistance) position these systems as essential components in next-gen smart factories and coastal urban developments.

(stainless steel floor grating)

FAQS on stainless steel floor grating

Q: What are the benefits of using stainless steel floor grating?

A: Stainless steel floor grating offers durability, corrosion resistance, and high load-bearing capacity, making it ideal for industrial, commercial, and outdoor environments. Its low-maintenance design ensures long-term performance in harsh conditions.

Q: Where is stainless floor grating commonly installed?

A: Stainless floor grating is widely used in platforms, walkways, drainage systems, and stair treads. It’s popular in food processing plants, marine settings, and chemical facilities due to its slip resistance and hygienic properties.

Q: How do I maintain stainless steel floor grates?

A: Regular cleaning with mild soap and water prevents debris buildup. Avoid abrasive tools to preserve the surface finish. For tough stains, use specialized stainless steel cleaners to maintain corrosion resistance.

Q: Can stainless floor grates support heavy machinery?

A: Yes, stainless floor grates are engineered to handle heavy loads, including industrial machinery and foot traffic. Their structural integrity depends on grade, thickness, and installation method for optimal safety.

Q: What types of stainless steel are used for floor grating?

A: Grades 304 and 316 are most common, with 316 offering superior corrosion resistance for saltwater or chemical exposure. The choice depends on environmental conditions and budget requirements.

-

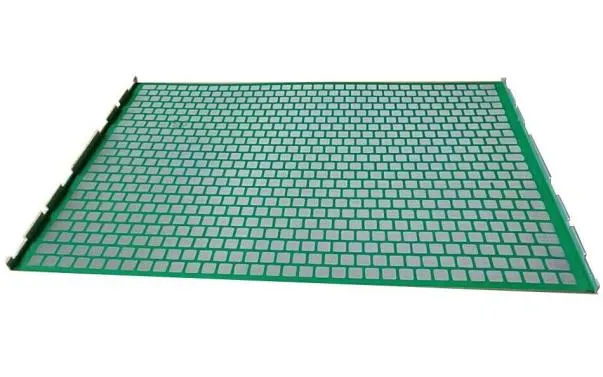

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025