- Industrizon, söder om Anping Town, Hengshui, Hebei, Kina.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  engelsk

engelsk  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- engelsk

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

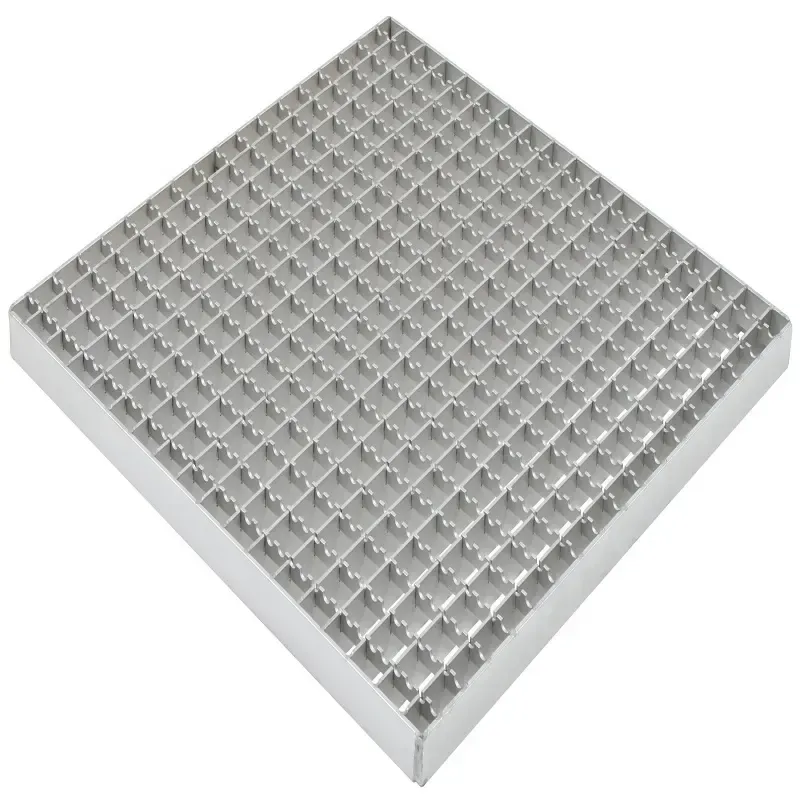

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty Applications

For industries demanding superior load-bearing capacity, safety, and resilience under harsh conditions, press locked steel grating delivers unmatched performance. Designed through a high-pressure locking process, this type of grating achieves structural rigidity and a clean aesthetic, making it a preferred solution for facilities in petroleum, chemical, power, and heavy manufacturing industries.

What Is Press Locked Steel Grating and How It’s Manufactured

Press locked steel grating is a type of welded grating where bearing bars and crossbars are mechanically pressed together under intense hydraulic pressure without welding. This locking method ensures a flush surface and tight grid alignment, creating an exceptionally stable platform with minimal maintenance needs.

Compared to standard welded grating, press locked grating provides a more uniform appearance and improved support, especially in areas requiring architectural finish or pedestrian comfort. The precise interlocking bars are often spaced according to project specifications, allowing flexibility in slip resistance, load-bearing, and air or light penetration.

Press locked bar grating is often made of carbon steel, stainless steel, or galvanized steel to ensure corrosion resistance and long-lasting performance. The grating is available in a variety of bar sizes and spacing configurations, adapting to numerous environments including offshore platforms, chemical processing plants, refineries, and wastewater treatment facilities.

Exceptional Seismic Performance and Impact Resistance of Press Locked Bar Grating

One of the key selling points of press locked steel grating is its ability to endure dynamic stresses and shocks, which makes it an excellent option for seismic zones or facilities with heavy moving equipment. The pressure-locked construction ensures high rigidity, effectively distributing loads and absorbing energy from ground motion or machinery vibration.

In seismic design applications, press locked grating is valued for its stability and load uniformity. Because there are no welded joints, the likelihood of fatigue cracks is significantly reduced, providing superior safety during earthquakes or other ground disturbances. This makes it an ideal walking surface on elevated platforms, stair treads, catwalks, or mezzanines in critical infrastructure.

Moreover, press locked bar grating shows outstanding impact resistance, which protects it from deformation under sudden loads such as dropped tools or machinery. The durable design minimizes the risk of denting, warping, or long-term stress damage.

Application of Press Locked Steel Grating in the Petroleum and Chemical Industry

The aggressive environments of the petroleum and chemical sectors demand grating solutions that resist chemical corrosion, bear heavy loads, and prevent fluid pooling. Press locked steel grating fulfills all these requirements with a high-performance profile and an open grid pattern that facilitates ventilation and drainage.

In refineries and chemical processing units, press locked grating is used for maintenance walkways, cooling tower platforms, tank access paths, trench covers, and overhead service lines. The open design prevents the buildup of flammable liquids, reducing safety hazards. Additionally, the slip-resistant surface—especially when serrated—is critical in preventing accidents in areas with frequent chemical spills or high humidity.

Press locked bar grating in stainless steel is often preferred for these environments due to its superior corrosion resistance and longer service life, which helps lower operational costs by minimizing maintenance and replacement needs. Gratings can also be fabricated with toe plates, kick plates, or edge banding for additional safety and custom-fit installations.

Aesthetic Value and Customization Potential of Press Locked Bar Grating

Beyond functional durability, press locked steel grating offers architectural appeal that makes it suitable for commercial buildings, stadiums, and public utilities where both appearance and performance matter. The uniform lines and tight tolerances of press locked bar grating create a visually clean and modern surface ideal for floor gratings, decorative facades, and ventilation covers.

Customization options include choice of bar sizes, spacings, finishes, and accessories. Galvanized press locked grating adds a reflective silver surface that resists oxidation, while painted finishes can match facility branding or safety color codes. Serrated surface options can be added for extra slip protection, especially in areas exposed to rain, oil, or snow.

Clients seeking customized shapes or load ratings can work directly with manufacturers to fabricate grating that perfectly matches their technical specifications. From square cut-outs to complex angular fits, press locked bar grating accommodates challenging layouts with industrial precision.

Press Locked Steel Grating FAQs

What makes press locked steel grating different from welded grating?

Press locked steel grating is manufactured by pressing crossbars into bearing bars under high pressure, offering a smoother surface and tighter fit compared to welded grating. It’s ideal for architectural and heavy-duty uses.

How does press locked grating perform in high-impact environments?

Press locked grating has excellent impact resistance due to its tight bar locking mechanism, making it perfect for areas with heavy traffic, dropped equipment, or seismic activity.

Why is press locked bar grating used in the chemical industry?

The corrosion resistance, drainage ability, and anti-slip features of press locked bar grating make it ideal for hazardous environments like chemical plants and oil refineries.

Can press locked steel grating be customized for unique architectural designs?

Yes, press locked steel grating can be customized in shape, spacing, finish, and size to fit architectural applications like building facades, floor panels, or ventilation grids.

What are the corrosion resistance options available for press locked bar grating?

Press locked bar grating is available in galvanized, painted, or stainless steel finishes to meet corrosion resistance needs in various environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNyheterAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNyheterAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNyheterAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNyheterAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNyheterAug.08,2025

-

Maximize Performance with Steel Walkway GratingNyheterAug.08,2025