- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Offshore Pipeline Support with Welded Wire Mesh Counterweights for Stability and Safety

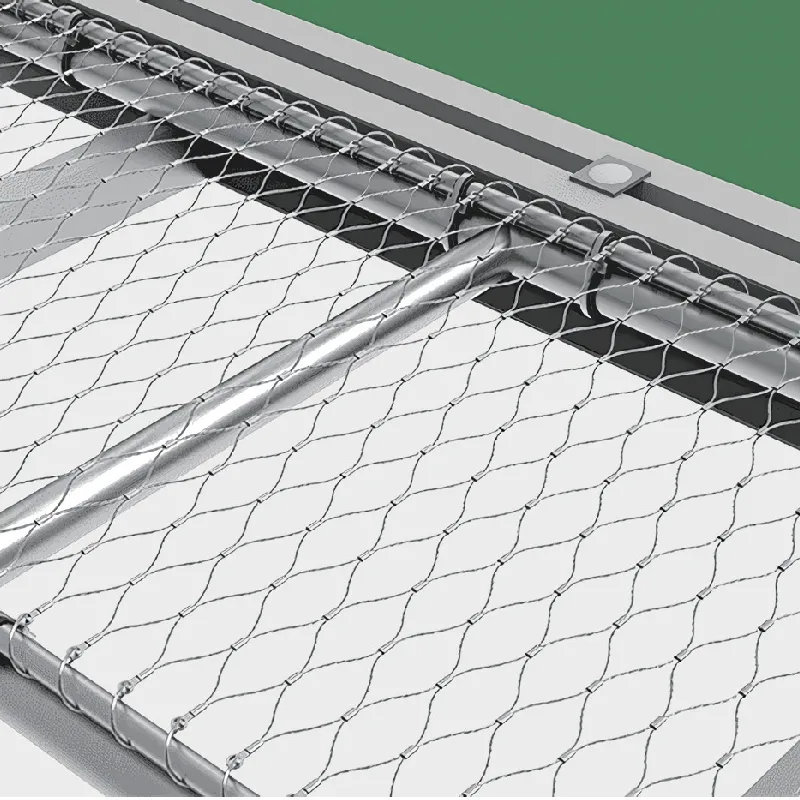

Offshore Pipeline Counterweight with Welded Wire Mesh

In the realm of offshore operations, the stability and durability of structures are paramount. One of the innovative solutions gaining traction is the use of welded wire mesh as a counterweight for offshore pipelines. This method offers a blend of strength, flexibility, and ease of installation, making it an ideal choice for enhancing the operational efficiency of underwater infrastructures.

Welded wire mesh consists of metal wires that are welded at intersections to form a grid-like structure. This design provides exceptional tensile strength and resistance to deformation, which is crucial when dealing with the dynamic and often harsh underwater environment. Offshore pipelines are subjected to numerous forces, including water currents, temperature fluctuations, and even seismic activities. The requirement for counterweights arises from the need to anchor these pipelines securely to the seabed, to prevent floatation or movement that could lead to catastrophic failures.

Offshore Pipeline Counterweight with Welded Wire Mesh

Installation of welded wire mesh counterweights is relatively straightforward. The mesh can be prefabricated to the desired specifications and then deployed to the installation site. This prefabrication approach not only saves time but also reduces labor costs associated with on-site assembly. Once in place, the mesh can be secured with concrete or other heavy materials, providing additional weight and stability.

offshore pipeline counterweight welded wire mesh

Furthermore, welded wire mesh is resistant to corrosion, a critical factor in the marine environment. The application of appropriate coatings, such as galvanized finishes or marine-grade paints, can further enhance this resistance, ensuring longevity and reliability. With minimal maintenance required, welded wire mesh counterweights can provide a sustainable solution to the challenges posed by offshore pipeline installations.

In addition to its practical benefits, utilizing welded wire mesh for counterweights aligns with the industry’s move towards more sustainable practices. The materials used are often recyclable, and the design can be optimized to use less raw material without compromising strength. This efficiency not only minimizes environmental impact but also contributes to cost savings for project developers.

Innovative engineering solutions like welded wire mesh counterweights represent the future of offshore pipeline management. By addressing the inherent challenges of underwater installations while promoting sustainability, this approach enhances safety and operational efficiency in the marine sector. As the demand for offshore energy sources continues to rise, the integration of advanced materials and techniques will be vital in ensuring the integrity and safety of these critical infrastructures.

In conclusion, the adoption of welded wire mesh as a counterweight for offshore pipelines is a testament to the ongoing evolution of engineering practices in response to environmental challenges. As the offshore industry looks toward the future, embracing such innovative solutions will not only enhance the performance of existing systems but also pave the way for new developments that prioritize safety, efficiency, and sustainability.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025