- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

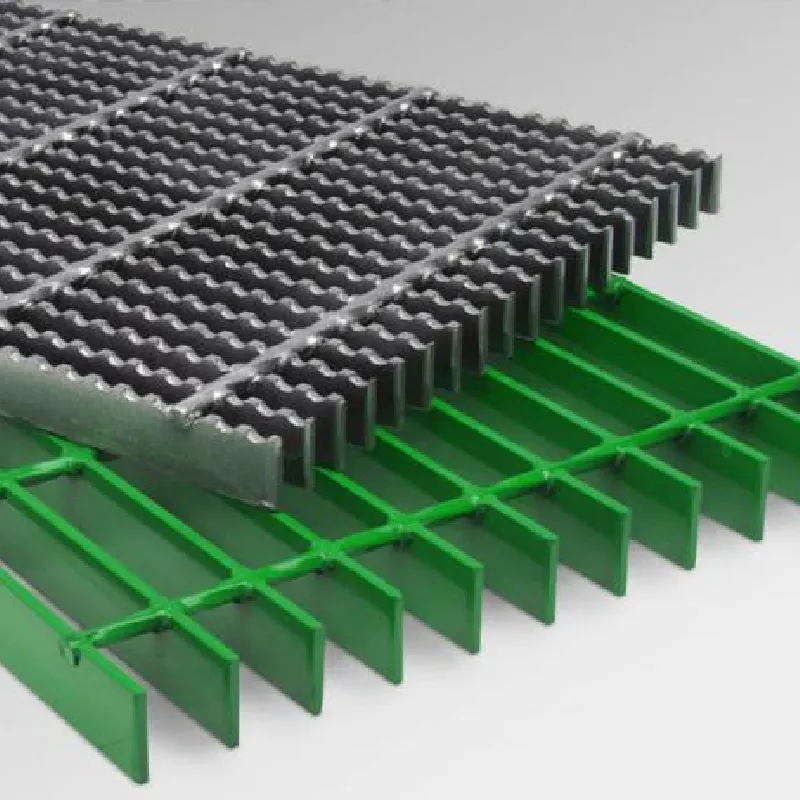

Heavy-Duty Welded Bar Grating: Durable Steel Grating Solutions

In the expansive landscape of industrial infrastructure and modern architecture, the integrity and reliability of foundational components are paramount. Among these, welded bar grating stands out as a critical element, offering unparalleled strength, versatility, and efficiency. Known also as welded steel grating or heavy-duty welded bar grating, this product is engineered to provide robust support, excellent ventilation, and safe walking surfaces across a multitude of demanding environments. Its construction, characterized by resistance welding of parallel bearing bars to perpendicular cross bars, creates a unified, high-strength panel that is indispensable in various sectors, from heavy industry to public utilities.

Industry Trends and Market Dynamics for Welded Bar Grating

The global market for grating products, particularly welded bar grating, is experiencing steady growth, driven by increasing investments in infrastructure, the expansion of industrial facilities, and the ongoing demand for safe and durable flooring solutions. According to recent market analysis, the global industrial flooring market, which includes grating, is projected to reach over USD 8 billion by 2028, with a significant compound annual growth rate (CAGR) attributed to developing economies and the need for robust industrial safety standards. Key trends include:

- Urbanization and Infrastructure Development: Rapid urbanization in emerging economies is fueling large-scale construction projects, including commercial complexes, public utilities, and transportation hubs, all requiring substantial amounts of grating for walkways, drains, and ventilation.

- Renewed Focus on Industrial Safety: Stringent safety regulations globally mandate the use of anti-slip, load-bearing surfaces in industrial settings, pushing the demand for high-quality welded bar grating.

- Sustainability and Durability: There's a growing preference for products with extended lifespans and minimal maintenance requirements. Welded steel grating, especially when galvanized, offers superior corrosion resistance and durability, aligning with sustainable construction practices.

- Technological Advancements in Manufacturing: Automation in the welding process and advancements in material science are leading to more cost-effective and higher-quality grating products, expanding their application possibilities.

The demand for heavy-duty welded bar grating, specifically, is increasing in sectors like oil & gas, mining, and power generation, where extreme loads and harsh conditions necessitate superior structural integrity.

Unveiling the Product: Welded Steel Grating Specifications

Our flagship product, Welded Steel Grating, is engineered to meet and exceed industry standards, providing reliable performance in the most challenging environments. These gratings are manufactured through a sophisticated resistance welding process that fuses bearing bars and cross bars into a strong, monolithic panel. The product can be accessed and explored further at: https://www.hfpetromesh.com/welded-steel-grating.html.

Key Technical Parameters of Welded Bar Grating

Understanding the technical specifications is crucial for selecting the appropriate welded bar grating for specific applications. Below is a detailed table outlining common parameters and their significance:

| Parameter | Description | Typical Range/Material | Relevance |

|---|---|---|---|

| Material Grade | Type of steel used for bearing and cross bars. | ASTM A36 (Carbon Steel), ASTM A1011 (Low Carbon Steel), Stainless Steel (304, 316, 316L), Aluminum Alloys (6061-T6) | Determines strength, corrosion resistance, and suitability for specific environments (e.g., chemical plants, marine). Carbon steel is common for general industrial use, while stainless steel is for corrosive or hygienic environments. |

| Bearing Bar Size (Height x Thickness) | Dimensions of the load-carrying bars. Height refers to depth, thickness is the width. | 20x3mm to 100x10mm (0.75"x0.125" to 4"x0.375") | Directly impacts load-bearing capacity and span capabilities. Larger dimensions handle heavier loads and wider spans. |

| Bearing Bar Spacing | Center-to-center distance between adjacent bearing bars. | 30mm, 40mm, 60mm (1-3/16", 1-3/4", 2-3/8") | Influences load distribution, light penetration, ventilation, and ability to prevent small objects from falling through. Smaller spacing for pedestrian safety, larger for maximum airflow. |

| Cross Bar Spacing | Center-to-center distance between adjacent cross bars. | 50mm, 100mm (2", 4") | Contributes to the lateral stability of the grating and its overall rigidity. Determines the size of the open mesh. |

| Surface Treatment | Protective coating applied after fabrication. | Hot-dip Galvanization (HDG) per ASTM A123, Mill Finish, Painted, Electro-polished | Crucial for corrosion resistance and aesthetics. HDG provides excellent long-term protection against rust in outdoor and harsh industrial settings. |

| Surface Type | Texture of the bearing bar surface. | Plain, Serrated | Serrated surfaces offer superior slip resistance, essential for areas prone to oil, water, or ice, enhancing safety in industrial walkways. |

| Panel Dimensions | Overall size of the manufactured grating panel. | Standard panels typically 995mm x 6000mm (3ft x 20ft) or customized. | Affects ease of installation and waste minimization during cutting. |

| Load Capacity | The maximum distributed or concentrated load a panel can safely support. | Varies significantly based on bar size, spacing, and span; calculated per industry standards (e.g., ANSI/NAAMM MBG 531-93). | Primary design consideration, ensuring structural integrity and safety for the intended application (e.g., pedestrian traffic, vehicular traffic). |

These parameters are meticulously chosen by our engineers to ensure that our welded bar grating products meet the specific structural and environmental demands of diverse projects. Our expertise in material science and structural engineering allows us to provide comprehensive guidance for optimal product selection.

The Meticulous Manufacturing Process of Welded Bar Grating

The superior quality and performance of welded bar grating are a direct result of its precise and technologically advanced manufacturing process. Unlike cast or forged products, welded steel grating relies on a highly efficient resistance welding method, which ensures a strong and durable bond between its components. Here’s a detailed breakdown of the process:

Process Flow of Welded Bar Grating Production

This streamlined process ensures that welded steel grating panels are produced with consistent quality, high precision, and excellent durability. The manufacturing process does not involve casting or forging the entire grating, but rather the precise assembly and welding of pre-manufactured bar stock, leveraging CNC-controlled machinery for accuracy.

Our commitment to quality extends to adhering to international detection standards, including ISO 9001 for quality management systems, and specific product performance standards such as ASTM A36/A1011 for material specifications and ANSI/NAAMM MBG 531-93 for grating design, fabrication, and installation. This ensures that every piece of welded bar grating we produce is of the highest caliber, guaranteeing a long service life and exceptional performance, often exceeding 20-30 years with proper maintenance, especially when hot-dip galvanized for enhanced corrosion protection.

Diverse Application Scenarios and Unique Advantages

Welded bar grating's inherent strength, open structure, and versatility make it indispensable across a vast array of industries and applications. Its ability to combine load-bearing capacity with excellent light, air, and liquid penetration offers unique advantages that other flooring materials cannot match.

Applicable Industries:

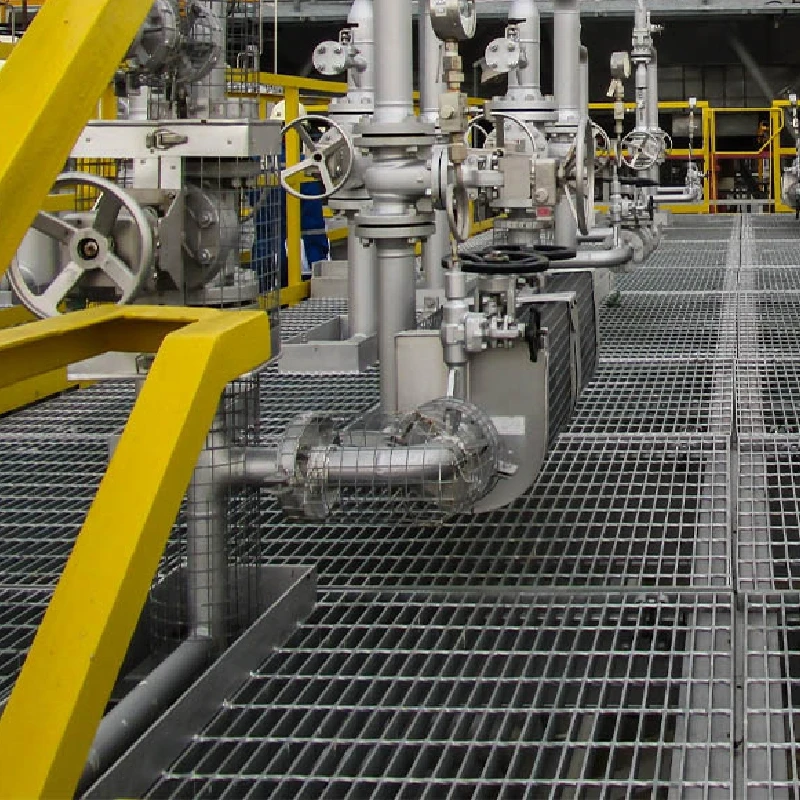

- Petrochemical & Oil & Gas: Used extensively for platforms, walkways, stair treads, and trench covers in refineries, drilling rigs, and processing plants. Its open structure allows for superior ventilation, dissipating heat and gas, which is critical in hazardous environments. The corrosion resistance of galvanized or stainless steel welded bar grating is paramount here.

- Power Generation: Found in power plants for boiler access platforms, catwalks, and mezzanines. The high strength of heavy-duty welded bar grating supports heavy machinery and frequent pedestrian traffic, while its open design aids in heat dissipation.

- Metallurgy & Mining: Essential in steel mills, foundries, and mining operations for robust platforms and grates that can withstand heavy loads, abrasive materials, and extreme temperatures.

- Water Treatment & Municipal Facilities: Employed in water and wastewater treatment plants for screen supports, clarifier walkways, and drain covers. The corrosion resistance to water and chemicals is vital, and the open design facilitates drainage and prevents accumulation.

- Marine & Offshore: Ideal for ship decks, offshore platforms, and dock structures due to its excellent slip resistance (especially serrated grating), drainage capabilities, and resistance to saltwater corrosion.

- Architectural & Commercial Buildings: Increasingly used for aesthetic and functional purposes in modern buildings, including sun shades, facade elements, infill panels, and decorative screens, offering both beauty and ventilation.

- Food & Beverage Industry: Stainless steel welded bar grating is preferred for its hygienic properties, ease of cleaning, and corrosion resistance in wash-down areas.

Product Advantages in Typical Scenarios:

- Enhanced Safety: Serrated welded bar grating provides exceptional anti-slip properties, significantly reducing the risk of falls in wet, oily, or icy conditions common in industrial settings. Its open mesh design also prevents debris accumulation, further enhancing safety.

- Superior Ventilation and Light Penetration: The open grid allows for free flow of air, heat, and light. This is crucial in environments where ventilation is necessary to disperse fumes, or where natural light needs to penetrate lower levels, contributing to energy efficiency (less need for artificial lighting) and a safer working environment.

- Excellent Drainage: Rain, spills, and wash-down water pass directly through the grating, preventing pooling and improving cleanliness and safety. This is particularly advantageous in outdoor applications or areas requiring frequent cleaning.

- High Strength-to-Weight Ratio: Despite being lightweight compared to solid flooring, welded steel grating offers exceptional strength and load-bearing capacity, making it cost-effective for construction and installation without compromising structural integrity. This also facilitates easier handling and installation, reducing labor costs.

- Corrosion Resistance and Longevity: Hot-dip galvanized welded bar grating provides a robust defense against rust and environmental degradation, significantly extending its service life and minimizing maintenance requirements. This translates to substantial long-term cost savings.

- Ease of Fabrication and Installation: Grating panels can be easily cut, formed, and installed on-site using simple clips or welding, allowing for quick and efficient project completion.

Choosing the Right Partner: Manufacturer Comparison and Trustworthiness

Selecting a reliable manufacturer for welded bar grating is as crucial as the product itself. The quality, durability, and performance of the grating directly depend on the manufacturer's expertise, processes, and commitment to standards. When comparing manufacturers, consider the following critical factors:

- Expertise & Experience: A manufacturer with a long track record and deep understanding of grating applications, engineering principles, and material science demonstrates high expertise. Look for companies with significant service years in the industry. For instance, our company has decades of experience supplying high-quality Welded Steel Grating to global projects, leveraging extensive practical knowledge.

- Quality Control & Certifications: Adherence to international quality management systems (like ISO 9001) and product-specific standards (such as ASTM, ANSI, NAAMM) is non-negotiable. Reputable manufacturers will provide material test certificates (MTCs), load test reports, and galvanization thickness reports upon request. Our strict adherence to ISO 9001 ensures every step from raw material sourcing to final product inspection meets stringent quality benchmarks.

- Customization Capabilities: Not all projects are standard. A manufacturer's ability to provide tailored solutions – custom panel sizes, shapes, material grades, surface treatments, and specialized cutouts – is a significant advantage. This ensures the grating perfectly fits the project's unique requirements, minimizing on-site modifications and waste.

- Lead Times & Production Capacity: Evaluate the manufacturer's production capacity and typical lead times for both standard and custom orders. Timely delivery is crucial for project schedules. A well-equipped facility with automated welding lines indicates efficient production.

- Technical Support & Customer Service: Comprehensive pre-sales consultation and post-sales support, including engineering design assistance, installation guidance, and problem resolution, are hallmarks of a trustworthy partner. Our dedicated technical team offers full support from conceptual design to project completion.

- Industry Recognition & Partnerships: Look for manufacturers with recognized industry affiliations, strong client testimonials, and a portfolio of successful projects. Collaborative partnerships with major engineering firms or construction companies reflect a high level of trust and capability.

- Warranty & After-Sales Policy: A clear warranty statement and a commitment to addressing any product-related issues post-delivery signifies confidence in their product and a dedication to customer satisfaction.

At HF Petromesh, our commitment to these principles ensures that our Welded Steel Grating not only meets but often exceeds client expectations. We combine cutting-edge manufacturing technology with stringent quality control and a highly experienced team to deliver exceptional products and unparalleled service. Our long-standing client relationships and recurring business are a testament to our trustworthiness and authority in the welded bar grating market.

Tailored Solutions: Customization and Engineering for Welded Bar Grating

While standard welded bar grating panels serve many general purposes, a significant strength of this product lies in its adaptability to highly specific project requirements through customization. Our engineering team specializes in developing bespoke welded bar grating solutions that perfectly integrate with complex structural designs and operational needs.

- Dimension and Shape Customization: We can fabricate welded steel grating panels in virtually any size and shape, including curved sections, circular grating, or irregular polygons, to fit architectural nuances or complex equipment layouts.

- Material and Finish Specification: Beyond standard carbon steel, we offer gratings in various stainless steel grades (304, 316, 316L) for enhanced corrosion resistance in aggressive chemical environments, or aluminum for lightweight applications. Surface finishes can range from mill finish to hot-dip galvanized, painted, or powder-coated, based on environmental exposure and aesthetic preferences.

- Load-Bearing and Span Optimization: Our engineers meticulously calculate the required bearing bar size and spacing to achieve specific load capacities and spans, ensuring the grating can safely support expected live and dead loads, whether it's heavy machinery, vehicular traffic, or pedestrian-only areas. This often involves detailed structural analysis and compliance with loading codes like ASCE 7 or local building codes.

- Cutouts and Banding: Precise cutouts for pipes, columns, and equipment penetrations are made during fabrication, eliminating the need for costly and time-consuming on-site modifications. Custom banding around irregular shapes or openings provides a clean, safe edge.

- Accessory Integration: We provide solutions with integrated stair nosings, toe plates, and various fixing methods (saddle clips, G-clips, Z-clips) to ensure seamless installation and enhanced functionality.

Our collaborative approach involves working closely with clients, architects, and structural engineers from the initial design phase through to delivery. Utilizing advanced CAD software and finite element analysis (FEA), we ensure that all custom welded bar grating solutions are not only precisely manufactured but also structurally sound, cost-effective, and optimized for performance.

Real-World Impact: Application Cases of Welded Steel Grating

The practical application of welded bar grating across diverse sectors powerfully illustrates its versatility and critical role in modern infrastructure. Here are illustrative scenarios:

Case Study 1: Large-Scale Petrochemical Complex Walkways (Middle East)

A major refinery expansion project required miles of elevated walkways and platforms for operational access. The challenge was to provide a durable, corrosion-resistant, and non-slip surface that could withstand extreme temperatures, chemical exposure, and continuous heavy foot traffic. Our heavy-duty welded bar grating (38x5mm bearing bars with 40mm spacing), hot-dip galvanized to ASTM A123 standards, was selected. The serrated surface ensured safety in potentially oily or wet conditions. The open structure facilitated excellent ventilation, aiding in the dispersion of potentially hazardous gases, while also allowing natural light to penetrate to lower levels, reducing energy consumption for lighting. The product's longevity, rated for over 25 years in such harsh conditions, significantly reduced long-term maintenance costs for the client. This project demonstrated our capacity to handle large volumes and deliver specialized solutions for critical infrastructure.

Case Study 2: Municipal Water Treatment Plant Trench Covers (North America)

A municipal water treatment facility needed robust, corrosion-proof trench covers for their clarifier tanks and pump stations. The environment was constantly wet and exposed to various treatment chemicals. We provided custom-fabricated stainless steel welded bar grating (Type 316L, 25x3mm bearing bars), with specific cutouts for piping and access points. The stainless steel material offered superior resistance to chloride-induced corrosion, ensuring a long operational life without degradation. The open design facilitated easy visual inspection of the trenches below and allowed for efficient drainage, preventing standing water and enhancing hygiene. This case underscored the importance of material selection and precise customization in specialized corrosive environments, ensuring compliance with health and safety regulations.

Case Study 3: Data Center Raised Flooring (Europe)

For a new state-of-the-art data center, a specialized raised flooring system was required that could support heavy server racks while providing maximum airflow for cooling. Our lightweight yet strong aluminum welded bar grating was chosen. The aluminum grating panels (20x3mm bearing bars with 30mm spacing) were custom-sized to fit the modular floor system. The primary advantage was the exceptional airflow through the open mesh, which dramatically improved the cooling efficiency of the server racks, contributing to significant energy savings (estimated 15-20% reduction in cooling costs) and ensuring optimal operating temperatures for sensitive equipment. The high strength-to-weight ratio simplified installation, while the non-magnetic properties of aluminum were also a critical benefit for the electronic environment.

These cases exemplify how welded bar grating, when properly specified and manufactured, provides enduring solutions that address complex challenges in infrastructure development and industrial operations, consistently delivering value through safety, efficiency, and longevity.

Quality Assurance, Compliance, and Longevity of Welded Steel Grating

The integrity and long-term performance of welded bar grating are inextricably linked to rigorous quality assurance protocols and adherence to established industry standards. At HF Petromesh, our commitment to quality is embedded in every stage of production, ensuring that our Welded Steel Grating products not only meet but often surpass international benchmarks.

Comprehensive Inspection and Testing:

- Material Certification: All raw materials (steel, stainless steel, aluminum) are sourced from approved suppliers and undergo stringent incoming inspection. Material test certificates (MTCs) confirming chemical composition and mechanical properties are meticulously reviewed to ensure compliance with standards like ASTM A36, ASTM A1011, or specific stainless steel grades.

- Dimensional Accuracy: During and after welding, panel dimensions, bearing bar spacing, cross bar spacing, and overall flatness are checked against design specifications using precision tools. This ensures seamless fit during installation.

- Welding Integrity: The critical resistance welds are visually inspected for full fusion and proper alignment. Destructive and non-destructive testing (such as pull tests) are periodically performed on sample batches to verify the strength of the weld joints, ensuring they meet load-bearing requirements.

- Surface Treatment Quality: For hot-dip galvanized welded bar grating, coating thickness is measured using magnetic gauges (per ASTM A123/A123M) to confirm adequate zinc coverage, which is essential for long-term corrosion protection. Adhesion and uniformity of the coating are also assessed.

- Load Testing: While design calculations are fundamental, selective load tests can be performed to validate the actual load-bearing capacity of the grating panels under specific conditions, providing empirical evidence of performance.

Compliance with Industry Standards:

Our products are designed and manufactured in strict adherence to globally recognized standards, which serve as benchmarks for quality, safety, and performance:

- ANSI/NAAMM MBG 531-93 (Metal Bar Grating Manual): This is the primary standard for bar grating design, fabrication, and installation in North America, covering dimensions, tolerances, load tables, and installation practices.

- ASTM Standards:

- ASTM A36/A36M: Standard Specification for Carbon Structural Steel (for carbon steel grating materials).

- ASTM A1011/A1011M: Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy with Improved Formability, and Ultra-High Strength.

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products (for galvanization quality).

- ASTM A1064: Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete (relevant for cross bars in some applications).

- ISO 9001: Our manufacturing facilities operate under an ISO 9001 certified Quality Management System, ensuring consistent product quality through well-defined processes, continuous improvement, and customer focus.

- OSHA Regulations: We ensure our grating products, when installed correctly, help clients comply with occupational safety and health regulations regarding walking/working surfaces, anti-slip requirements, and fall protection.

Service Life and Warranty:

With proper material selection and surface treatment, our welded bar grating boasts an exceptional service life. Hot-dip galvanized carbon steel grating, when installed and maintained correctly, can last 20 to 50 years even in challenging outdoor industrial environments. Stainless steel versions offer even longer lifespans in highly corrosive conditions. We stand behind the quality of our products with comprehensive warranty provisions that cover material defects and manufacturing faults, providing our clients with peace of mind and demonstrating our unwavering commitment to trustworthiness and product reliability.

Frequently Asked Questions (FAQ) about Welded Bar Grating

A1: Welded bar grating is a structural panel composed of parallel load-bearing bars joined at right angles by resistance-welded cross bars. This process involves applying high current and pressure at each intersection, fusing the metals without filler. This creates a strong, monolithic panel ideal for industrial platforms, walkways, and covers.

A2: The most common materials include carbon steel (often hot-dip galvanized for corrosion resistance), various grades of stainless steel (304, 316, 316L for corrosive or hygienic environments), and aluminum alloys (e.g., 6061-T6 for lightweight and non-magnetic applications).

A3: Load capacity depends primarily on the bearing bar dimensions (height and thickness), the spacing between bearing bars, and the unsupported span. Engineers use industry standards like ANSI/NAAMM MBG 531-93 and structural engineering principles to calculate the safe load for specific configurations and applications.

A4: The most common and effective treatment is hot-dip galvanization (HDG), which provides excellent long-term corrosion protection. Other options include mill finish (untreated), painted, or powder-coated. Surface type can also be plain or serrated; serrated surfaces offer superior slip resistance, crucial for safety in wet or oily conditions.

A5: Absolutely. Welded bar grating can be custom-fabricated to specific dimensions, shapes (e.g., circular, curved), with precise cutouts for pipes or columns, and tailored to meet specific load requirements, material needs, and surface finishes.

A6: Heavy-duty welded bar grating is used in demanding environments where significant loads are present. Common applications include industrial platforms, mezzanines, trench covers for heavy vehicle traffic, power plant walkways, bridge decking, and heavy machinery access platforms in industries such as oil & gas, mining, and metallurgy.

A7: With proper material selection (e.g., hot-dip galvanized carbon steel or stainless steel) and appropriate maintenance, welded bar grating can have an exceptionally long service life, often exceeding 20 to 50 years, even in harsh industrial or outdoor environments. Our products come with a robust warranty, reflecting our confidence in their durability.

Delivery and Customer Support

Understanding the critical timelines of industrial projects, we prioritize efficient production and reliable delivery for our welded bar grating. Our typical lead times vary based on project scope and customization requirements but are consistently communicated and adhered to. We offer comprehensive logistical support, managing domestic and international shipping to ensure your Welded Steel Grating arrives on schedule, anywhere in the world.

Beyond delivery, our commitment extends to unparalleled customer support. Our experienced team provides:

- Technical Consultation: Expert advice on grating selection, load calculations, material suitability, and surface treatments.

- Installation Guidance: Support and recommendations for proper installation techniques to ensure safety and longevity.

- After-Sales Service: Prompt response to any queries or concerns post-delivery, ensuring complete client satisfaction.

Our goal is to be more than just a supplier; we aim to be a long-term partner in your success, providing reliable products and comprehensive solutions that you can trust.

Conclusion: The Enduring Value of Welded Bar Grating

The ubiquity and continued demand for welded bar grating across critical industrial and commercial sectors underscore its intrinsic value. As the backbone of safe and efficient access systems, platforms, and drainage solutions, welded steel grating offers a unique combination of exceptional strength, versatility, ventilation capabilities, and long-term durability. From its meticulous manufacturing process, ensuring precise and robust joins, to its ability to be customized for virtually any application, it stands as a testament to intelligent engineering.

By adhering to stringent international standards, providing comprehensive technical support, and focusing on client-specific needs through tailored solutions, manufacturers like HF Petromesh ensure that every piece of heavy-duty welded bar grating delivered contributes to safer, more efficient, and more sustainable infrastructure worldwide. As industries continue to evolve, the adaptability and inherent advantages of welded bar grating will undoubtedly cement its position as an indispensable component in the future of industrial and architectural design.

References and Further Reading:

- National Association of Architectural Metal Manufacturers (NAAMM). "NAAMM MBG 531-93 Metal Bar Grating Manual" (Often referenced by professionals for grating design and fabrication guidelines).

https://www.naamm.org/store/product/mbg-531 - ASTM International. Official site for standards related to materials and testing.

https://www.astm.org/ - ISO - International Organization for Standardization. Official site for quality management and other standards.

https://www.iso.org/home.html - Galvanizers Association. "The Longevity of Hot Dip Galvanizing" (Provides insights into the lifespan of galvanized coatings in various environments).

https://www.galvanizing.org.uk/articles/longevity-hot-dip-galvanizing/

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025