- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

mar . 05, 2025 02:01

Back to list

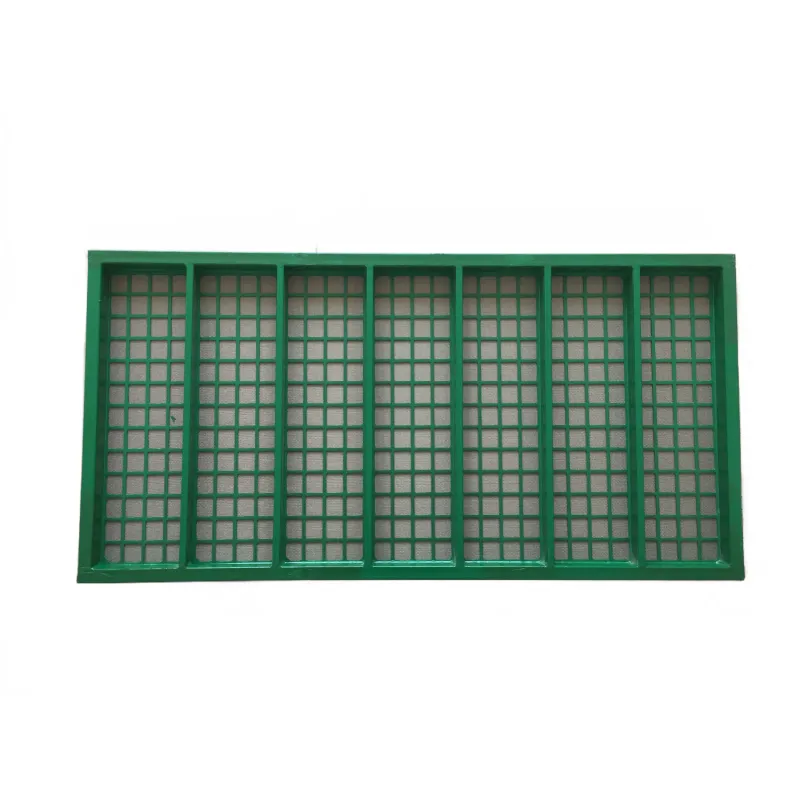

15w4 grating

Exploring the Intricacies of 15w4 Grating A Comprehensive Guide

From an authoritative standpoint, it is critical to consider the standards and specifications surrounding 15w4 grating. Adherence to industry standards such as those set forth by the National Association of Architectural Metal Manufacturers (NAAMM) ensures that the gratings meet required safety and durability benchmarks. Product certifications and compliance with set standards foster trust and reliability in these components when incorporated into projects. Trustworthiness with respect to 15w4 grating also stems from tooling utilization for precision in manufacture. Advanced CNC machining techniques are employed to ensure the meticulous spacing and alignment of bearing and cross bars. This precision in engineering not only enhances the performance capabilities of the grating but also reduces the likelihood of human error, resulting in a product that consistently performs at or above originally specified metrics. When analyzing the installation and maintenance aspects, 15w4 grating demonstrates significant ease of installation due to its modular design. This contributes to reduced labor costs and installation times—an attractive proposition for project managers constrained by tight timelines and budgets. Moreover, maintenance isn't a significant concern, owing to the durability of the materials. Regular inspections and minor cleaning to prevent build-up of debris are sufficient to maintain its functionality and aesthetic quality over time. This maintenance simplicity ensures long-term reliability and performance, saving resources and ensuring ongoing safety in operational environments. In conclusion, the multifaceted virtues of 15w4 grating make it a cornerstone component in various industrial and commercial implementations. Its strength, longevity, and versatility are underpinned by a foundation of reputable expertise and stringent adherence to industry standards. Whether it’s the build quality secured through precision manufacturing or the reliable performance backed by user experience, the case for 15w4 grating as a primary choice in industrial applications is compelling and well-supported. Choosing 15w4 grating is a proactive step towards ensuring structural resilience, operational efficiency, and an enhanced safety profile in high-demand environments.

From an authoritative standpoint, it is critical to consider the standards and specifications surrounding 15w4 grating. Adherence to industry standards such as those set forth by the National Association of Architectural Metal Manufacturers (NAAMM) ensures that the gratings meet required safety and durability benchmarks. Product certifications and compliance with set standards foster trust and reliability in these components when incorporated into projects. Trustworthiness with respect to 15w4 grating also stems from tooling utilization for precision in manufacture. Advanced CNC machining techniques are employed to ensure the meticulous spacing and alignment of bearing and cross bars. This precision in engineering not only enhances the performance capabilities of the grating but also reduces the likelihood of human error, resulting in a product that consistently performs at or above originally specified metrics. When analyzing the installation and maintenance aspects, 15w4 grating demonstrates significant ease of installation due to its modular design. This contributes to reduced labor costs and installation times—an attractive proposition for project managers constrained by tight timelines and budgets. Moreover, maintenance isn't a significant concern, owing to the durability of the materials. Regular inspections and minor cleaning to prevent build-up of debris are sufficient to maintain its functionality and aesthetic quality over time. This maintenance simplicity ensures long-term reliability and performance, saving resources and ensuring ongoing safety in operational environments. In conclusion, the multifaceted virtues of 15w4 grating make it a cornerstone component in various industrial and commercial implementations. Its strength, longevity, and versatility are underpinned by a foundation of reputable expertise and stringent adherence to industry standards. Whether it’s the build quality secured through precision manufacturing or the reliable performance backed by user experience, the case for 15w4 grating as a primary choice in industrial applications is compelling and well-supported. Choosing 15w4 grating is a proactive step towards ensuring structural resilience, operational efficiency, and an enhanced safety profile in high-demand environments.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025