- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

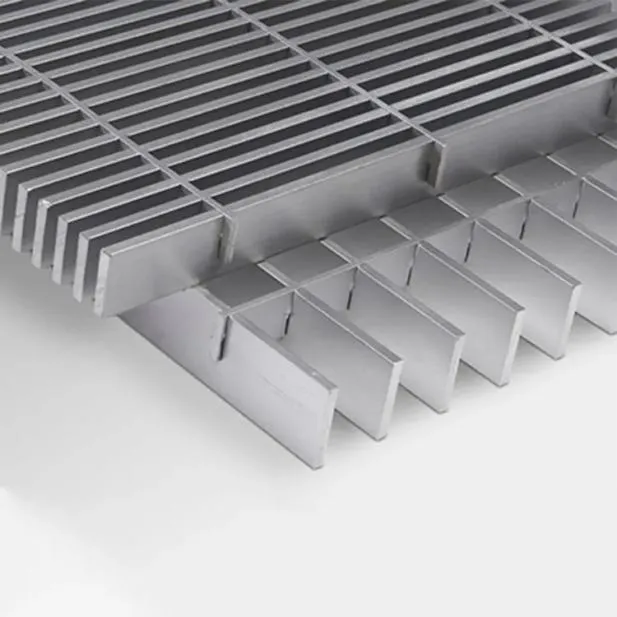

Aluminum Grating Design Guidelines and Technical Specifications for Optimal Performance

Aluminum Grating Specifications A Comprehensive Guide

Aluminum grating is a versatile and robust solution widely used in a variety of industrial applications due to its lightweight, corrosion resistance, and high strength-to-weight ratio. When selecting aluminum grating, it is essential to understand the specifications that govern its design, performance, and suitability for specific projects. This article provides an overview of aluminum grating specifications, helping you make informed choices for your application needs.

Material Composition

The primary material used for aluminum grating is typically aluminum alloy 6061 or 6063, known for their excellent corrosion resistance and weldability. These alloys are standard in structural applications, offering good mechanical properties and durability. The choice of alloy will depend on the specific load requirements and environmental conditions where the grating will be installed.

Types of Aluminum Grating

Aluminum grating comes in several types, each suited for different applications

1. Bar Grating Comprising parallel bars that run in one direction, this type is ideal for heavy-duty applications where high load-bearing capacity is required.

2. Expanded Metal Grating This type features a series of expanded metal sheets that provide a lightweight, slip-resistant surface, making it suitable for walkways and platforms.

3. Perforated Grating Designed with holes punched into the material, perforated grating offers superior drainage and is often used in areas exposed to liquids.

Each type has its specific load ratings, which should align with the intended use to ensure safety and performance

.Load Capacity

aluminum grating specifications

Understanding load capacity is critical in selecting aluminum grating. Load capacity is typically categorized into a few specific ratings

- Live Load This represents the weight of people and movable objects that the grating can support. - Dead Load This accounts for the weight of the grating itself plus any permanent fixtures.

Manufacturers often provide load tables that detail the maximum loads permissible for different spans and configurations. It is crucial to calculate the anticipated load and choose grating that exceeds this value for safety.

Dimensions and Spacing

Aluminum grating is available in various dimensions, including different thicknesses, widths, and lengths. Furthermore, the spacing between the bars or expanded sections can also vary. Typical bar thickness ranges from 1/8 to 1/4, while widths can be anywhere from 1 to 4. Manufacturers can customize grating to meet specific project requirements, including special dimensions or shapes for irregularly shaped areas.

Surface Treatment

While aluminum is naturally resistant to rust, surface treatment can enhance its aesthetic appeal and longevity. Options such as anodizing or powder coating can provide additional layers of protection, improve slip resistance, and add color choices. Anodizing involves electrochemically treating the aluminum, making it more durable, while powder coating offers various colors and finishes.

Safety Considerations

When installing aluminum grating, safety is paramount. It is essential to ensure that the grating complies with relevant safety codes and regulations for slip resistance and load bearing. Non-slip surface treatments may be advisable in high-traffic areas to prevent accidents.

Conclusion

In summary, aluminum grating is a highly effective material used across various industries due to its strengths and adaptability. Understanding the specifications surrounding aluminum grating—including types, load capacities, dimensions, surface treatments, and safety considerations—empowers engineers and architects to select the right product for their projects. By prioritizing these specifications, you can ensure the longevity, safety, and efficiency of your aluminum grating installations.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025