- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 20, 2025 06:06

Back to list

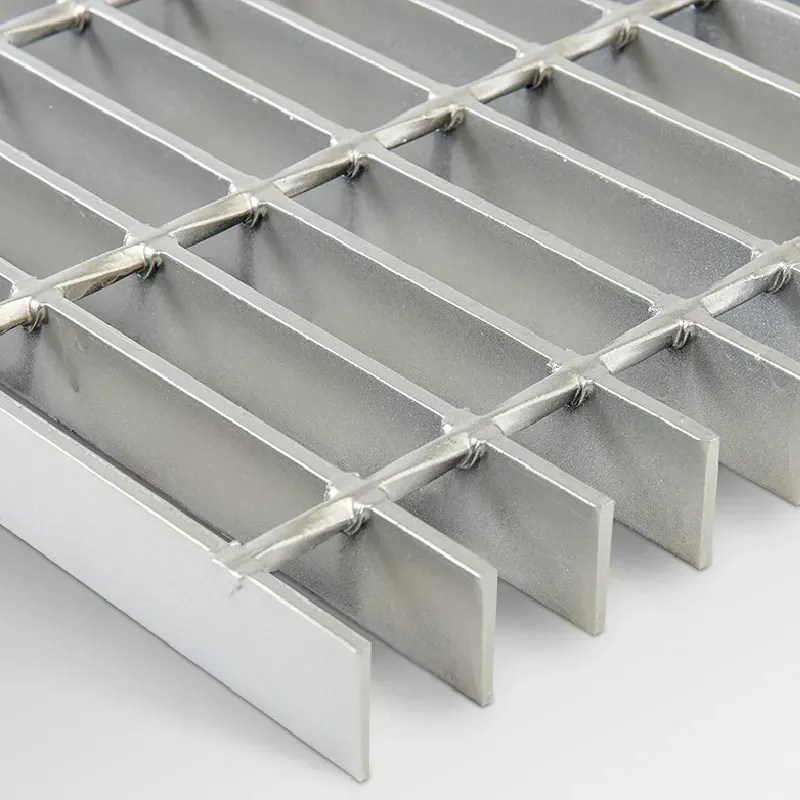

metal walkways gratings

Galvanized steel walkways stand as a remarkable innovation in the world of construction and architecture, providing unparalleled benefits that cater to various industries. Renowned for their durability, safety, and low maintenance, these walkways have revolutionized how businesses ensure secure and efficient passage across different environmental conditions. Companies across the globe are now more frequently opting for galvanized steel, recognizing the long-term advantages it offers in terms of both performance and cost-effectiveness.

From an operational perspective, the low maintenance requirements of galvanized steel walkways contribute to cost savings over time. Unlike other materials that may require frequent inspections or repairs due to corroding issues, galvanized steel offers peace of mind. The structural integrity remains intact over years, leading to fewer disruptions in operations and lower maintenance budgets. This reliability also contributes to environmental sustainability, as longer-lasting materials reduce the frequency of replacements and associated resource consumption. Moreover, galvanized steel is recyclable, making it a sustainable choice in today's environmentally conscious market. After serving its purpose, the material can be recycled and repurposed, supporting circular economic principles. This aspect further elevates its standing as a preferred material in industries moving towards greener solutions. To further enhance the safety and utility of galvanized steel walkways, additional features such as anti-slip surfaces and customizable designs are available. These adaptations are critical in areas prone to wet or oily conditions, where slip hazards could pose significant safety risks. Custom designs also allow businesses to optimize walkways for specific operational needs, whether it’s accommodating heavy loads or ensuring smooth access for equipment. In conclusion, the expertise brought by galvanized steel walkways transcends beyond basic infrastructure. Its development reflects a deep understanding of industrial needs, merging safety, durability, and sustainability. Businesses seeking reliable solutions for walkway installations find galvanized steel to be a trusted choice, supported by a legacy of performance and adaptability to future challenges. Embracing such innovations not only enhances operational efficiency but also demonstrates a commitment to employee safety and environmental responsibility.

From an operational perspective, the low maintenance requirements of galvanized steel walkways contribute to cost savings over time. Unlike other materials that may require frequent inspections or repairs due to corroding issues, galvanized steel offers peace of mind. The structural integrity remains intact over years, leading to fewer disruptions in operations and lower maintenance budgets. This reliability also contributes to environmental sustainability, as longer-lasting materials reduce the frequency of replacements and associated resource consumption. Moreover, galvanized steel is recyclable, making it a sustainable choice in today's environmentally conscious market. After serving its purpose, the material can be recycled and repurposed, supporting circular economic principles. This aspect further elevates its standing as a preferred material in industries moving towards greener solutions. To further enhance the safety and utility of galvanized steel walkways, additional features such as anti-slip surfaces and customizable designs are available. These adaptations are critical in areas prone to wet or oily conditions, where slip hazards could pose significant safety risks. Custom designs also allow businesses to optimize walkways for specific operational needs, whether it’s accommodating heavy loads or ensuring smooth access for equipment. In conclusion, the expertise brought by galvanized steel walkways transcends beyond basic infrastructure. Its development reflects a deep understanding of industrial needs, merging safety, durability, and sustainability. Businesses seeking reliable solutions for walkway installations find galvanized steel to be a trusted choice, supported by a legacy of performance and adaptability to future challenges. Embracing such innovations not only enhances operational efficiency but also demonstrates a commitment to employee safety and environmental responsibility.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025