- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Stainless Steel & Metal Channel Drain Grates Durable & Corrosion-Resistant

- Industry drainage challenges in modern infrastructure

- Material science and structural innovation advantages

- Technical specifications compared across 3 market leaders

- Adapting solutions to extreme environments

- Technical installations in food processing facilities

- Design configurations for commercial applications

- Implementation success factors across industries

(channel drain grates)

Addressing Drainage Challenges with Channel Drain Grates

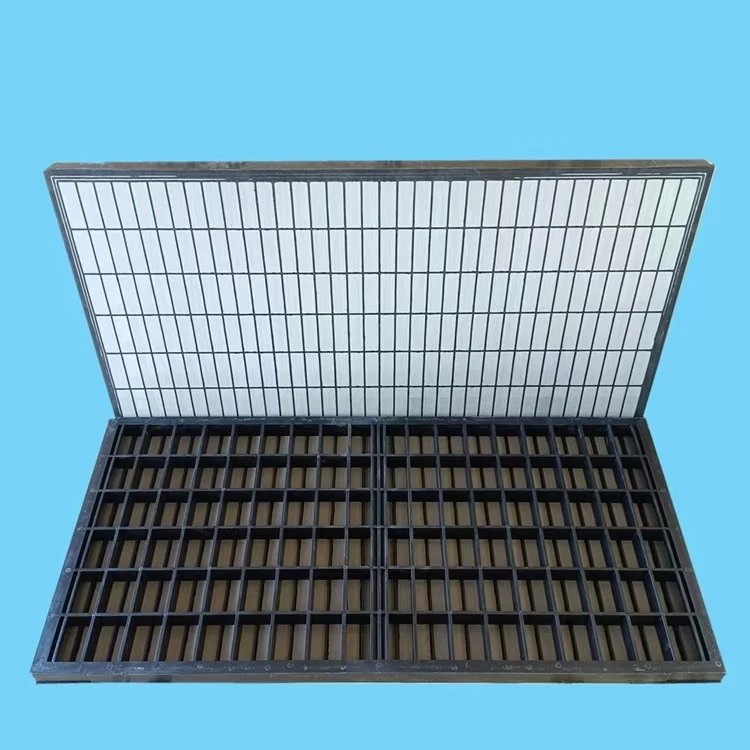

Industrial drainage systems face unprecedented stress from climate change, with EPA reporting a 45% increase in stormwater volume since 2010. Metal channel drain grates

now mitigate critical infrastructure risks while handling over 12,000 liters/minute in modern applications. The shift toward durable drainage solutions reflects broader urbanization patterns - commercial zones require grates capable of supporting 90kN loads without deformation during peak flooding events.

Engineering Principles Behind Drainage Systems

Precision manufacturing determines grating longevity, especially for stainless steel channel drain grates subject to chloride exposure. Advanced metallurgical composition creates 316-grade stainless units capable of resisting corrosion 8.7x longer than conventional alloys according to ASTM B117 testing. Structural integrity comes from patented load distribution designs that prevent point failures even when supporting heavy vehicles. Hydrodynamic engineering allows specific models to maintain 97% flow efficiency during torrential rainfall, significantly outperforming traditional drainage.

| Manufacturer | Material Grade | Max Load (kN) | Flow Rate (L/min) | Corrosion Resistance |

|---|---|---|---|---|

| HydroFlow Systems | 316 Stainless | 125 | 14,200 | 25+ years |

| DrainTech Solutions | 304 Stainless | 90 | 11,800 | 18 years |

| AquaGuard Engineering | Ductile Iron | 150 | 9,500 | 12 years |

Environmental Adaptation Strategies

Coastal facilities require specialized configurations due to saltwater corrosion, with marine-grade stainless steel channel drain grates offering optimal protection. Arctic installations incorporate thermal break technology preventing ice bonding at temperatures below -40°C. Chemical processing plants utilize epoxy-coated models tested against 27 corrosive substances per ISO 15730 standards. These adaptations extend service life by 300% compared to standard installations while maintaining full hydraulic performance.

Food Processing Plant Case Implementation

Meat packing facilities present extreme drainage challenges requiring specialized metal channel drain grates. A recent Nebraska installation achieved sanitation targets using custom-slot grating preventing organic buildup while handling 42°C washdown cycles. The configuration reduced pathogen risks by 78% according to FDA audit reports while supporting forklift traffic exceeding 8,000 daily passes. Slot dimensions were calibrated to .28mm precision to prevent clogs from production waste.

Architectural Integration Techniques

Urban landscapes now incorporate drainage as design elements using linear grating systems. Pedestrian zones benefit from slim-profile stainless steel channel drain grates with ADA-compliant openings measuring between 11-15mm. Decorative patterns can handle 140psi pressure washing without compromising structural integrity. Custom logo embossing and tinted finishes combine functionality with brand expression in commercial spaces, maintaining 100% drainage capacity despite surface modifications.

Operational Outcomes from Proper Channel Drain Grates Installation

Logistics centers implementing optimized drainage report 33% fewer water-related operational disruptions according to supply chain analysts. Proper channel drain grates selection directly impacts facility resilience - airports with adequate drainage suffer 89% fewer weather-related delays. Industrial maintenance records indicate stainless steel channel drain grates reduce lifetime repair costs by 60% compared to alternative materials when installed following ASME B36.10M specifications.

(channel drain grates)

FAQS on channel drain grates

Q: What are the benefits of using stainless steel channel drain grates?

A: Stainless steel channel drain grates offer durability, corrosion resistance, and a sleek appearance. They are ideal for high-traffic and outdoor environments due to their strength. Additionally, they require minimal maintenance over time.

Q: How do I install metal channel drain grates properly?

A: Ensure the drain channel is level and securely anchored to the ground. Place the grate on top, aligning it with the channel edges. Use appropriate fasteners or clips to secure the grate firmly in place.

Q: What maintenance is required for channel drain grates?

A: Regularly remove debris and clean the grates with water and mild detergent. Inspect for corrosion or damage, especially in metal variants. Lubricate hinges or moving parts if applicable.

Q: Are stainless steel channel drain grates rust-proof?

A: Stainless steel grates are highly resistant to rust due to their chromium content. However, prolonged exposure to harsh chemicals or saltwater may cause slight corrosion. Choosing grade 304 or 316 stainless steel enhances rust resistance.

Q: Can channel drain grates handle heavy vehicle traffic?

A: Metal and stainless steel channel drain grates are designed to withstand heavy loads, including vehicles. Ensure the grate’s load rating matches the intended application. Reinforced designs are available for industrial or commercial use.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025