- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

феб . 07, 2025 03:11

Back to list

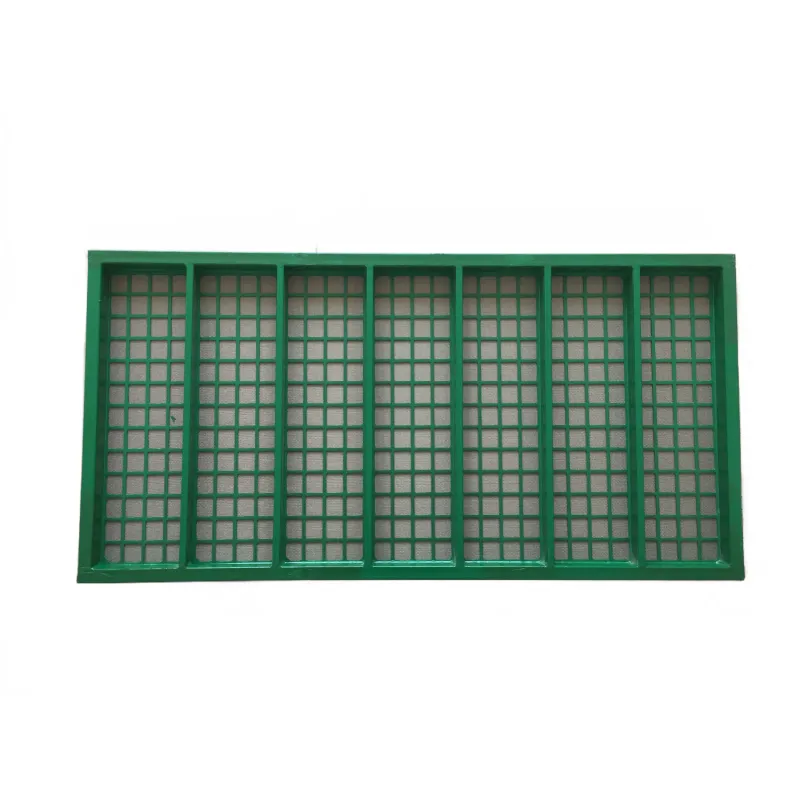

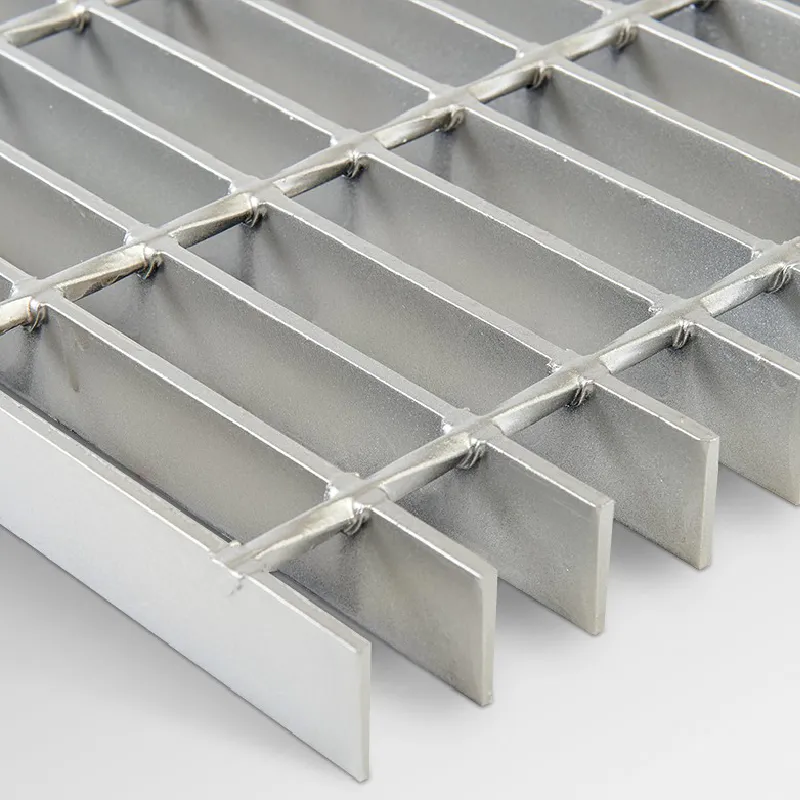

metal grating for sale

Metal grating is a versatile material widely used across various industries, offering exceptional strength, durability, and adaptability. This article delves into the intricacies of metal grating, exploring its types, applications, and esteemed significance in enhancing industrial processes.

The adaptability of metal grating makes it invaluable in a myriad of applications. Industrially, it is employed for walkways, platforms, safety barriers, drainage covers, and stair treads. Its ability to withstand heavy loads while providing a non-slip surface is crucial for workplace safety and efficiency. Furthermore, in architectural domains, metal grating is utilized in facades, ceiling panels, and sunscreens, offering a modern aesthetic while maintaining structural integrity. In the realm of environmental sustainability, metal grating offers exceptional benefits. Materials used in its construction, such as steel, are highly recyclable. This recyclability reduces waste and supports the circular economy, an increasingly important consideration in contemporary industrial practice. Moreover, the open pattern of metal grating facilitates environmental integration, allowing for natural light and air penetration, which contributes to energy savings in building designs. The expertise and craftsmanship involved in producing metal grating underline its authoritative position in industrial components. Manufacturers adhere to stringent quality controls and standards, such as ISO certifications, ensuring each piece of metal grating meets the precise specifications needed for its intended application. This attention to detail augments the trustworthiness of metal grating products, providing end-users with peace of mind regarding their investment's durability and reliability. In environments where corrosion resistance is vital, particularly in coastal or chemical exposure locations, stainless steel grating is often preferred. Its resilience against rust and chemical wear extends its lifecycle, thereby reducing maintenance costs and downtime. Ultimately, metal grating stands as a testament to engineering ingenuity, where function meets form in creating a material that not only supports but also enhances the diverse demands of modern industries. Whether incorporated into infrastructural builds or industrial machinery, the reliable performance of metal grating continues to be a cornerstone of advanced manufacturing practices. In conclusion, understanding what metal grating is, and recognizing its various forms and applications, underscores its indispensable role in both industrial and commercial contexts. By integrating metal grating into projects, stakeholders can ensure optimized performance, safety, and sustainability—a trifecta of benefits that defines the modern industrial landscape.

The adaptability of metal grating makes it invaluable in a myriad of applications. Industrially, it is employed for walkways, platforms, safety barriers, drainage covers, and stair treads. Its ability to withstand heavy loads while providing a non-slip surface is crucial for workplace safety and efficiency. Furthermore, in architectural domains, metal grating is utilized in facades, ceiling panels, and sunscreens, offering a modern aesthetic while maintaining structural integrity. In the realm of environmental sustainability, metal grating offers exceptional benefits. Materials used in its construction, such as steel, are highly recyclable. This recyclability reduces waste and supports the circular economy, an increasingly important consideration in contemporary industrial practice. Moreover, the open pattern of metal grating facilitates environmental integration, allowing for natural light and air penetration, which contributes to energy savings in building designs. The expertise and craftsmanship involved in producing metal grating underline its authoritative position in industrial components. Manufacturers adhere to stringent quality controls and standards, such as ISO certifications, ensuring each piece of metal grating meets the precise specifications needed for its intended application. This attention to detail augments the trustworthiness of metal grating products, providing end-users with peace of mind regarding their investment's durability and reliability. In environments where corrosion resistance is vital, particularly in coastal or chemical exposure locations, stainless steel grating is often preferred. Its resilience against rust and chemical wear extends its lifecycle, thereby reducing maintenance costs and downtime. Ultimately, metal grating stands as a testament to engineering ingenuity, where function meets form in creating a material that not only supports but also enhances the diverse demands of modern industries. Whether incorporated into infrastructural builds or industrial machinery, the reliable performance of metal grating continues to be a cornerstone of advanced manufacturing practices. In conclusion, understanding what metal grating is, and recognizing its various forms and applications, underscores its indispensable role in both industrial and commercial contexts. By integrating metal grating into projects, stakeholders can ensure optimized performance, safety, and sustainability—a trifecta of benefits that defines the modern industrial landscape.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025