- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Factors Influencing the Cost of Steel Grating and Its Applications in Construction

The Cost of Steel Grating Factors, Applications, and Economic Impact

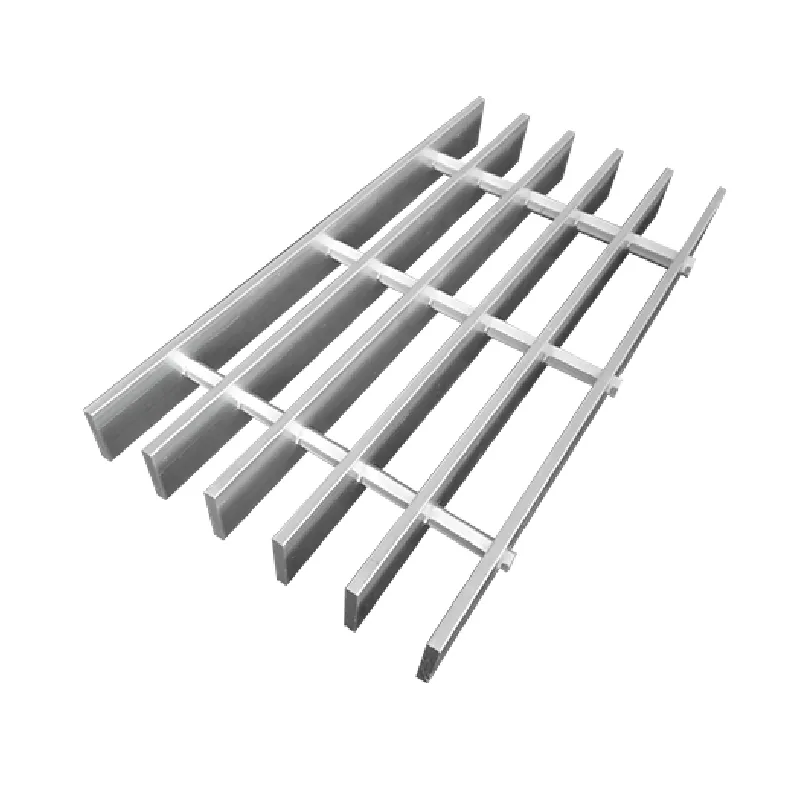

Steel grating is a widely utilized material in various industries, known for its strength, durability, and versatility. It consists of a series of metal bars, typically welded together to create a load-bearing surface. While its applications span from industrial flooring to pedestrian walkways and drainage covers, an essential aspect that businesses must consider is the cost of steel grating. Understanding the factors influencing this cost can help organizations make informed decisions about their projects.

Factors Influencing the Cost of Steel Grating

1. Material Type The cost of steel grating is significantly influenced by the type of steel used. There are various grades of steel, each with different price points based on their strength, corrosion resistance, and manufacturing processes. Common types include carbon steel, stainless steel, and aluminum, with stainless steel often being the most expensive due to its anti-corrosive properties.

2. Manufacturing Process The way steel grating is manufactured also affects its cost. Options include welded, press-locked, and swage-locked grating. Welded grating, while robust and suited for heavy loads, may have higher production costs due to labor intensity. In contrast, press-locked grating can be less expensive but may not provide the same level of strength under heavy loads.

3. Thickness and Mesh Size The thickness of the bars and the size of the openings in the grating directly impact the cost. Thicker bars typically mean higher load capacity, but they also increase material costs. Similarly, smaller mesh sizes can enhance safety and usability in certain applications but might come at a premium.

4. Custom Fabrication Many projects require custom sizes and specifications for steel grating. Custom fabrication increases costs due to the additional labor and materials required. Organizations must weigh the benefits of a tailored product against the potential for higher expenses.

5. Market Conditions The price of raw steel fluctuates based on global market conditions, supply and demand dynamics, and tariffs. During periods of high demand or shortage, costs can rise significantly. Businesses should keep abreast of market trends to time their purchases effectively.

cost of steel grating

Applications of Steel Grating

Steel grating finds applications across various sectors, including

- Industrial Facilities Used for flooring and walkways in factories and warehouses, where durability and safety are critical. - Construction Serves as a platform for scaffolding or as functional elements in building design. - Transportation Commonly featured in bridges and walkways over water, providing lightweight yet high-strength solutions. - Waste Management Utilized in drainage systems to allow for effective runoff while preventing larger debris from clogging systems.

Economic Impact

Investing in steel grating can initially appear costly, but its durability and longevity often translate into lower maintenance and replacement costs over time. Businesses that opt for steel grating typically find that it enhances safety and efficiency in their operations, contributing to overall productivity improvements.

Moreover, sustainable practices are becoming increasingly significant, and steel grating is often recyclable, further providing economic and environmental benefits. As the emphasis on sustainability grows, the demand for durable materials like steel grating is expected to rise.

Conclusion

The cost of steel grating is influenced by a multitude of factors, including material type, manufacturing processes, and market dynamics. Understanding these components aids businesses in making informed decisions, optimizing their investments, and benefitting from the long-term value steel grating offers. As industries continue to grow and evolve, steel grating will remain a critical material, balancing cost with performance across various applications.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025