- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

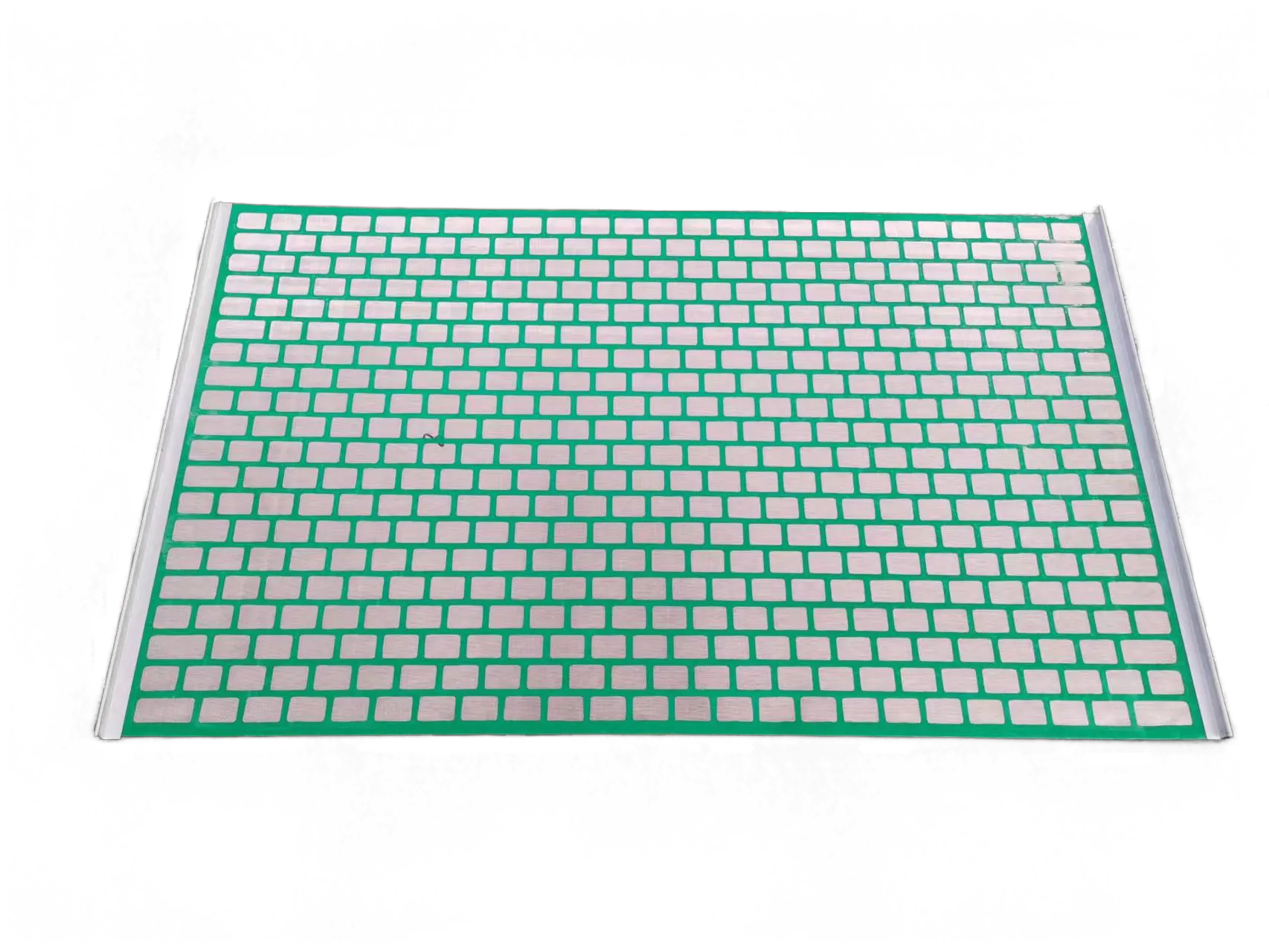

Offshore Pipeline Support Using Welded Wire Mesh Counterweights for Enhanced Stability

Offshore Pipeline Counterweight The Role of Welded Wire Mesh

In the world of offshore engineering, ensuring the stability and safety of submerged pipeline systems is an ongoing challenge. One innovative solution that has gained traction is the use of counterweights, particularly those incorporating welded wire mesh. This material not only enhances the structural integrity of the counterweight system but also addresses several environmental and operational challenges faced in the offshore sector.

Understanding Offshore Pipelines and Their Challenges

Offshore pipelines are vital for transporting oil, gas, and other resources from beneath the ocean floor to onshore processing facilities. However, these pipelines encounter numerous challenges such as buoyancy, ocean currents, and seabed instability. To mitigate these issues, engineers often employ counterweights designed to keep the pipelines securely in place, reducing the risk of damage from movements or environmental factors.

The Function of Counterweights

Counterweights serve a crucial function in stabilizing offshore pipelines. By providing additional weight, they counteract buoyancy forces that can cause pipelines to rise or shift out of position. This ensures that the pipelines remain buried under the seabed, reducing the likelihood of exposure to environmental hazards or damage caused by fishing activities.

The Role of Welded Wire Mesh

Welded wire mesh has emerged as a favored material in the construction of offshore pipeline counterweights. Its unique properties make it particularly well-suited for this application. The mesh is constructed from high-quality steel wire, which is welded at intersections to create a grid-like structure. This design offers several benefits

offshore pipeline counterweight welded wire mesh

1. Strength and Durability Welded wire mesh provides exceptional tensile strength, which is crucial in withstanding the harsh conditions of offshore environments. The corrosion resistance of the steel can also be enhanced through various coatings or galvanization, ensuring longevity.

2. Flexibility in Design The mesh can be customized to fit various shapes and sizes, allowing engineers to optimize the design according to specific pipeline needs. This adaptability is essential when dealing with diverse seabed conditions.

3. Weight Optimization Using welded wire mesh allows for the creation of lightweight yet strong counterweights. This is particularly important in offshore installations where heavy materials can be challenging to handle and transport.

4. Environmental Considerations The open structure of welded wire mesh promotes water and sediment flow, minimizing disruption to marine ecosystems. This is an important factor in environmentally sensitive areas where maintaining the ecological balance is critical.

5. Cost-Effectiveness Compared to solid materials, the use of welded wire mesh can reduce material costs and labor intensity. The ease of installation and maintenance further enhances its appeal throughout the lifecycle of the pipeline.

Conclusion

As the demand for offshore resources continues to grow, the challenges associated with the installation and maintenance of pipelines will persist. Utilizing innovative solutions like welded wire mesh in counterweight systems is not only a testament to engineering ingenuity but also an essential step toward ensuring safe and efficient offshore operations. The ability of welded wire mesh to provide strength, flexibility, and adaptability makes it an indispensable component in the ongoing quest for effective offshore pipeline solutions. As technology advances further, we can anticipate even more refined applications of this material, paving the way for safer and more sustainable offshore endeavors in the future.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025