- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

јан . 23, 2025 03:38

Back to list

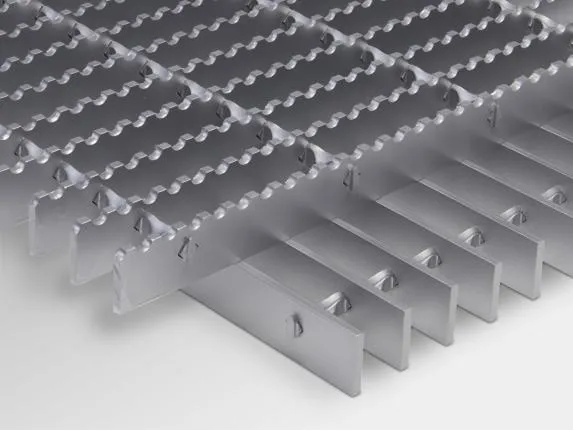

heavy-duty welded bar grating

Bar grating metal is an essential component across multiple sectors, known for its durability, strength, and versatility. This product is integral in creating safe, efficient environments for industries ranging from manufacturing to public infrastructure. By understanding the different facets of bar grating metal, businesses can optimize their facilities for safety, efficiency, and cost-effectiveness.

Moreover, the expertise involved in the manufacturing of bar grating metal further elevates its reliability. Advanced techniques such as electro-forging, where high voltage is used to secure the intersections, ensure maximum strength and durability. This process, along with strict quality control measures, guarantees that each piece of grating meets the required specifications and performs reliably under pressure. Trustworthiness is another crucial factor in the selection of bar grating metal. Industry leaders invest heavily in research and development, alongside stringent testing protocols, to ensure their products maintain the highest safety and performance standards. Furthermore, they often provide extensive warranties and guarantees, offering peace of mind in high-stakes industrial applications. Transparent communication regarding material sourcing, manufacturing processes, and testing outcomes solidifies trust with clients, ensuring long-term relationships. From a practical experience perspective, businesses that have integrated bar grating metal into their operations frequently report increased safety and efficiency. The non-slip surface of grating dramatically reduces accident risks, particularly in areas prone to moisture or lubricants. Additionally, the low-maintenance nature of metal grating frees up resources, allowing teams to focus on productivity rather than upkeep. Companies can also customize grating to fit specific dimensions and requirements, making it a versatile choice for various applications. In conclusion, bar grating metal is more than just a functional component; it is a foundational element for creating safe and efficient industrial environments. With its unmatched strength, versatility, and reliability, it plays a critical role in the infrastructure of modern business operations. By collaborating with reputable manufacturers and leveraging expert insights, businesses can ensure they select the most suitable grating solutions tailored to their specific needs, thereby enhancing both safety and productivity across their facilities.

Moreover, the expertise involved in the manufacturing of bar grating metal further elevates its reliability. Advanced techniques such as electro-forging, where high voltage is used to secure the intersections, ensure maximum strength and durability. This process, along with strict quality control measures, guarantees that each piece of grating meets the required specifications and performs reliably under pressure. Trustworthiness is another crucial factor in the selection of bar grating metal. Industry leaders invest heavily in research and development, alongside stringent testing protocols, to ensure their products maintain the highest safety and performance standards. Furthermore, they often provide extensive warranties and guarantees, offering peace of mind in high-stakes industrial applications. Transparent communication regarding material sourcing, manufacturing processes, and testing outcomes solidifies trust with clients, ensuring long-term relationships. From a practical experience perspective, businesses that have integrated bar grating metal into their operations frequently report increased safety and efficiency. The non-slip surface of grating dramatically reduces accident risks, particularly in areas prone to moisture or lubricants. Additionally, the low-maintenance nature of metal grating frees up resources, allowing teams to focus on productivity rather than upkeep. Companies can also customize grating to fit specific dimensions and requirements, making it a versatile choice for various applications. In conclusion, bar grating metal is more than just a functional component; it is a foundational element for creating safe and efficient industrial environments. With its unmatched strength, versatility, and reliability, it plays a critical role in the infrastructure of modern business operations. By collaborating with reputable manufacturers and leveraging expert insights, businesses can ensure they select the most suitable grating solutions tailored to their specific needs, thereby enhancing both safety and productivity across their facilities.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025