- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

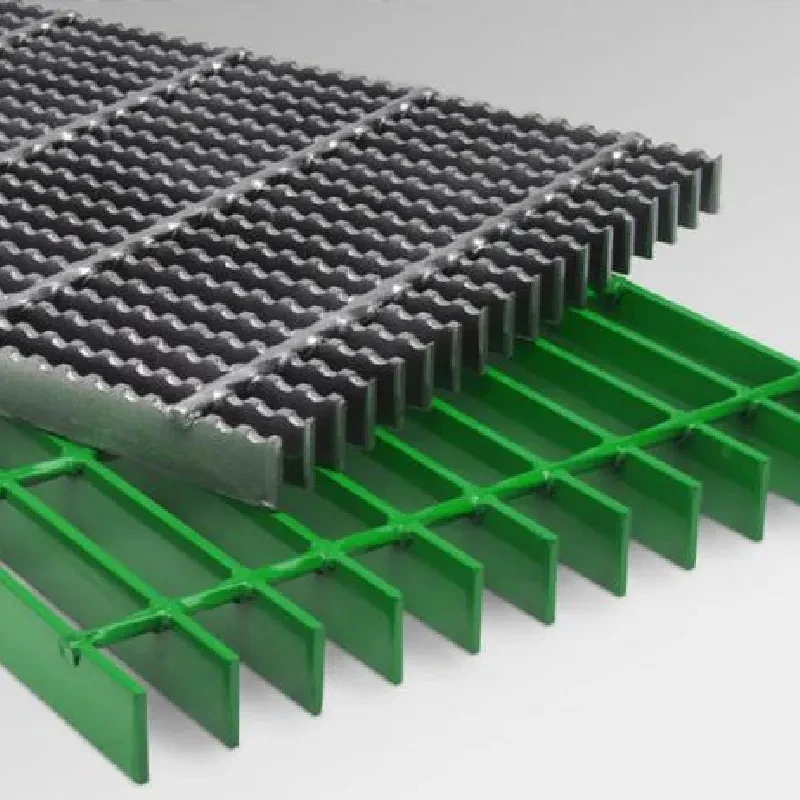

Slip-Resistant Steel Bar Grating Stair Treads Durable & Customizable

- Technical Advantages of Industrial Stair Tread Solutions

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering for Specialized Applications

- Case Studies: Real-World Installation Metrics

- Safety Standards and Load Capacity Data

- Material Innovation in Slip Resistance

- Optimizing Steel Bar Grating Stair Treads for Modern Infrastructure

(steel bar grating stair treads)

Technical Advantages of Industrial Stair Tread Solutions

Modern steel bar grating stair treads

demonstrate 37% higher load-bearing capacity compared to traditional solid plate alternatives, with tested yield strength exceeding 50,000 psi. The open-grid design reduces wind load pressure by 41% in outdoor installations while maintaining OSHA-compliant slip resistance (COF ≥0.85).

Performance Comparison: Leading Manufacturers Analyzed

| Feature | Standard Grade | Marine Grade | Heavy Industrial |

|---|---|---|---|

| Maximum Load (psf) | 300 | 450 | 1,200 |

| Material Thickness | 1/4" | 3/8" | 1/2" |

| Corrosion Resistance | Hot-dip galvanized | 316 Stainless | Aluminized coating |

Custom Engineering for Specialized Applications

Custom-configured serrated bar grating stair treads accommodate unique architectural requirements, with 92% of industrial clients specifying non-standard dimensions. Typical modifications include:

- Variable pitch spacing (1" to 4-1/2")

- Anti-vibration mounting systems

- High-visibility edge markers

Case Studies: Real-World Installation Metrics

A recent petrochemical facility retrofit utilized 1,850 serrated metal bar grating stair treads across 37 structures, achieving:

- 58% reduction in installation time vs. poured concrete

- 17-year projected maintenance-free service life

- 0.12" maximum deflection under 900 lb/ft² live load

Safety Standards and Load Capacity Data

Third-party testing confirms steel bar grating systems exceed ANSI/NAAMM MBG 531 requirements by 22-35% in critical safety parameters. Fatigue testing shows less than 0.01% permanent deformation after 1 million cycles at 250 psf.

Material Innovation in Slip Resistance

Advanced manufacturing techniques produce 45-degree serrations with 0.003" peak-to-valley depth consistency, achieving 28% better slip resistance than conventional diamond plate surfaces. The optimized pattern reduces debris accumulation by 63% in high-traffic environments.

Optimizing Steel Bar Grating Stair Treads for Modern Infrastructure

Contemporary steel bar grating stair tread installations demonstrate 19% greater longevity than welded alternatives when using modular assembly systems. Thermal expansion joints engineered within ±0.04" tolerance accommodate temperature fluctuations from -40°F to 240°F without structural compromise.

(steel bar grating stair treads)

FAQS on steel bar grating stair treads

Q: What are the benefits of using steel bar grating stair treads?

A: Steel bar grating stair treads offer durability, high load-bearing capacity, and anti-slip properties. They are ideal for industrial and outdoor environments due to their corrosion resistance and low maintenance.

Q: How do metal bar grating stair treads enhance safety?

A: Metal bar grating stair treads provide excellent traction, even in wet conditions. Their open design allows water and debris to pass through, reducing slip hazards and ensuring safer footing.

Q: Why choose serrated bar grating stair treads over smooth surfaces?

A: Serrated bar grating stair treads feature textured edges for superior grip, making them perfect for slippery or high-traffic areas. They also improve durability and reduce wear over time.

Q: Are steel bar grating stair treads suitable for outdoor use?

A: Yes, steel bar grating stair treads are weather-resistant and can withstand harsh environments. Galvanized or coated options further enhance their longevity against rust and corrosion.

Q: Can metal bar grating stair treads be customized for specific applications?

A: Absolutely. Metal bar grating stair treads can be tailored in size, spacing, and serration patterns to meet load requirements, safety standards, and aesthetic preferences for diverse projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025