- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Shk . 10, 2025 10:32

Back to list

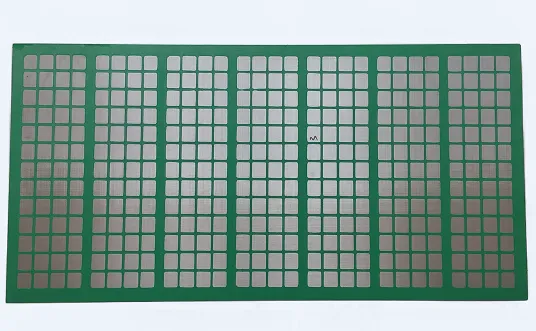

Steel Grating

Enhancing efficiency and safety in industrial environments often begins with a single, underestimated component the metal grid walkway. Universally valued for its robustness and practicality, these walkways are integral to industries ranging from manufacturing to oil and gas, providing operators and maintenance staff with a reliable and secure platform.

Trustworthiness in walkway systems is bolstered by regular maintenance regimes. Keeping walkways clean and inspecting them for signs of wear and tear—such as corrosion on fasteners or loss of structural integrity—is vital. An effective maintenance program prolongs the viable life of the walkway system, creating a dependable environment that fosters trust among users and compliance with regulatory inspections. For industries looking to expand or modernize their infrastructure, integrating automated monitoring technologies into metal grid walkway systems can revolutionize the scope of their utility. Sensors that detect stress levels or structural deformations in real-time can alert maintenance teams before issues escalate, thereby preventing unforeseen accidents and maintaining operational flow. Metal grid walkways are not just a product but a vital cog in the vast machinery of industry. Their strategic deployment, backed by empirical insights and professional expertise, enhances their role beyond mere access pathways. These walkways become instrumental in maintaining safety, reliability, and efficiency across industrial operations, a testament to their engineered excellence and indispensable functionality. In making a purchasing decision, consulting with experts in industrial safety and grid walkway technology empowers businesses to decide on systems that align perfectly with their operational demands and environmental conditions. Such a dedicated approach ensures investment in metal grid walkways is not only cost-effective but also catalytic in propelling industrial efficiency and safety to new heights.

Trustworthiness in walkway systems is bolstered by regular maintenance regimes. Keeping walkways clean and inspecting them for signs of wear and tear—such as corrosion on fasteners or loss of structural integrity—is vital. An effective maintenance program prolongs the viable life of the walkway system, creating a dependable environment that fosters trust among users and compliance with regulatory inspections. For industries looking to expand or modernize their infrastructure, integrating automated monitoring technologies into metal grid walkway systems can revolutionize the scope of their utility. Sensors that detect stress levels or structural deformations in real-time can alert maintenance teams before issues escalate, thereby preventing unforeseen accidents and maintaining operational flow. Metal grid walkways are not just a product but a vital cog in the vast machinery of industry. Their strategic deployment, backed by empirical insights and professional expertise, enhances their role beyond mere access pathways. These walkways become instrumental in maintaining safety, reliability, and efficiency across industrial operations, a testament to their engineered excellence and indispensable functionality. In making a purchasing decision, consulting with experts in industrial safety and grid walkway technology empowers businesses to decide on systems that align perfectly with their operational demands and environmental conditions. Such a dedicated approach ensures investment in metal grid walkways is not only cost-effective but also catalytic in propelling industrial efficiency and safety to new heights.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025