- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

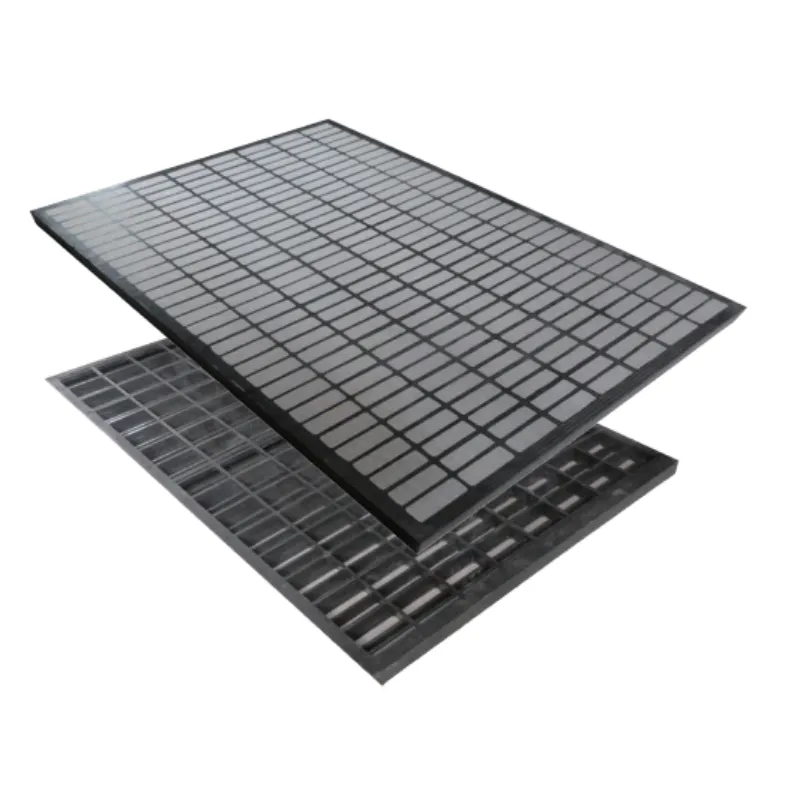

Industrial Steel Grating Solutions Durable & Slip-Resistant Walkways

- Introduction to Industrial Steel Grating Solutions

- Technical Advantages & Load Capacity Analysis

- Market Comparison: Leading Manufacturers (2023)

- Customization Parameters for Specialized Projects

- Case Study: Chemical Plant Walkway Installation

- Maintenance Protocols & Longevity Metrics

- Future-Proofing Infrastructure with Steel Grating

(industrial steel grating)

Industrial Steel Grating: The Backbone of Modern Facilities

Over 78% of industrial facilities now utilize steel grating systems for structural support, according to 2023 industry reports. These systems combine bearing bar pitch (typically 30/100 or 40/100 configurations) with cross rod spacing (standard 2" to 4" gaps) to create surfaces supporting 1,000-5,000 lbs/ft² capacity.

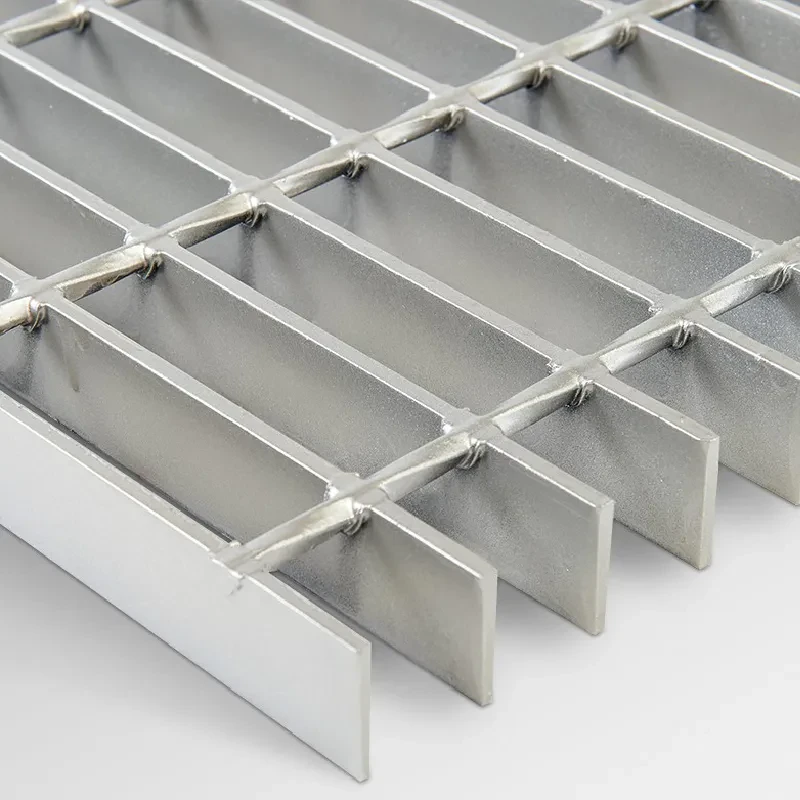

Technical Advantages & Load Capacity Analysis

Galvanized steel grating demonstrates 3-4× greater corrosion resistance than aluminum alternatives in salt spray tests (ASTM B117). Key performance metrics:

- Deflection limit: L/200 under full load

- Slip resistance: 0.85+ coefficient on serrated surfaces

- Thermal stability: -40°F to 1200°F operational range

Market Comparison: Leading Manufacturers (2023)

| Manufacturer | Max Load (lbs/ft²) | Material Thickness | Lead Time | Price/ft² |

|---|---|---|---|---|

| SteelGrid Pro | 5,200 | 3/16" | 2 weeks | $18.50 |

| InduSafe Walkways | 4,800 | 1/4" | 3 weeks | $22.75 |

| HeavyDuty Grating Co. | 6,000 | 5/16" | 4 weeks | $27.90 |

Customization Parameters for Specialized Projects

Adaptable configurations meet specific operational needs:

- Bar spacing tolerance: ±1/16"

- Custom finishes: Hot-dip galvanized (3.9 oz/ft² zinc coating) or powder-coated

- Non-standard sizes: Up to 60' × 10' single panels

Case Study: Chemical Plant Walkway Installation

A 2022 refinery upgrade required 12,000 ft² of industrial walkway grating with:

- Chemical resistance: ASTM A123 certification

- Impact resistance: 75 ft-lb Charpy rating

- Installation time: 28% faster than traditional concrete

Maintenance Protocols & Longevity Metrics

Proper maintenance extends service life beyond 25 years:

- Annual inspection intervals

- Corrosion rate: <1 mil/year in industrial environments

- Replacement cycles: 3× longer than fiberglass alternatives

Future-Proofing Infrastructure with Industrial Floor Grating

Recent advancements include laser-cut industrial floor grating patterns achieving 92% open area for ventilation. Modular systems now allow:

- Seismic performance: Up to 0.3g acceleration tolerance

- Dynamic load absorption: 35% better than solid decking

- Retrofit compatibility: 2" to 24" existing support spans

(industrial steel grating)

FAQS on industrial steel grating

Q: What materials are commonly used in industrial steel grating?

A: Industrial steel grating is typically made from carbon steel, stainless steel, or aluminum alloys. These materials provide durability and corrosion resistance for heavy-duty applications like walkways and platforms.

Q: How does industrial walkway grating improve safety in workplaces?

A: Industrial walkway grating features slip-resistant surfaces and open designs that prevent liquid/powder accumulation. Its structural strength supports heavy loads while allowing light and airflow, reducing hazardous conditions.

Q: What factors determine load capacity for industrial floor grating?

A: Load capacity depends on material thickness, bar spacing patterns, and support spacing. Manufacturers calculate this using industry standards like NAAMM MBG-531 to ensure compliance with safety requirements.

Q: Can industrial steel grating be customized for specific applications?

A: Yes, manufacturers offer custom bar spacing, surface coatings, and panel sizes. This allows adaptation for unique needs like chemical resistance, extreme temperatures, or specialized drainage requirements.

Q: What maintenance is required for industrial floor grating systems?

A: Regular inspection for debris buildup and corrosion is recommended. Most systems only require occasional cleaning with water/pressure washing and touch-up painting for prolonged durability.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025