- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

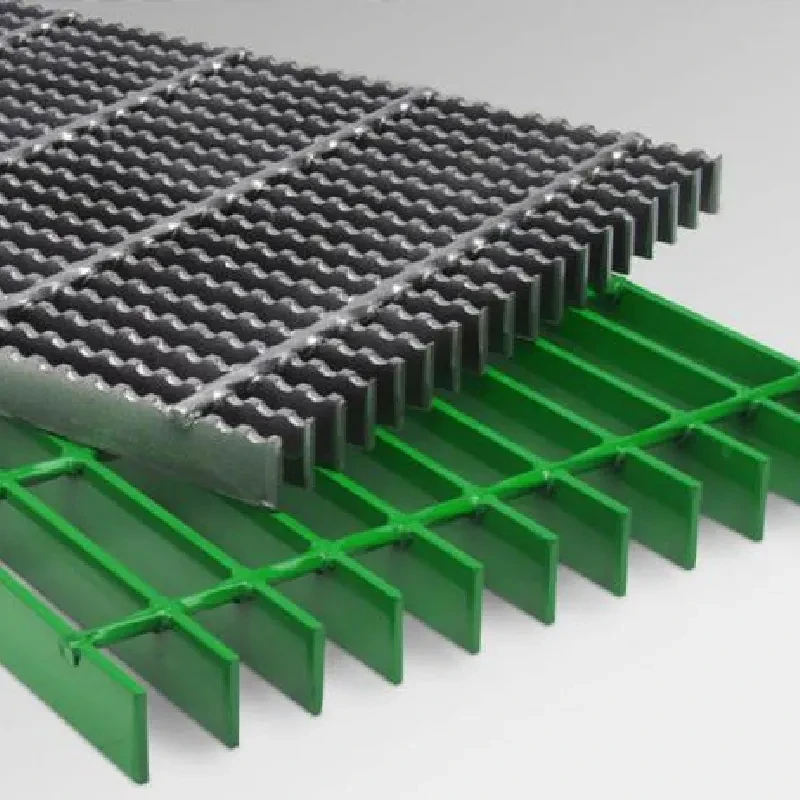

lightweight grating

Lightweight Grating Innovations and Applications

In the realm of optics and material science, a fascinating development has emerged in the form of lightweight grating. This technology has garnered significant attention for its potential applications in various fields, such as telecommunications, spectroscopy, and photonics. The combination of lightweight materials with diffraction grating principles offers a promising future for both scientific research and practical applications.

Understanding Lightweight Grating

At its core, a diffraction grating is an optical component that splits light into its component wavelengths. Traditional gratings are often made from heavy materials like glass or metal, which can limit their application in portable devices. Lightweight grating incorporates newer materials and manufacturing techniques, making them not only easier to handle but also more efficient in a variety of environments. Common materials used include plastics, thin films, and advanced composites, which substantially reduce weight without compromising performance.

The reduction in weight opens new avenues for innovation, especially in industries where weight constraints are critical, such as aerospace, automotive, and mobile electronics. From compact spectrometers to high-performance sensors, lightweight grating makes it possible to achieve superior optical performance while maintaining portability and ease of integration.

Manufacturing Techniques

The fabrication of lightweight gratings has evolved significantly in recent years. Traditional methods, such as ruling or etching on glass or metal substrates, have been largely supplemented by modern techniques like nanoimprint lithography, laser direct writing, and polymer-based processes. These advanced manufacturing methods not only allow for the production of various grating patterns with nanometer precision but also support mass production, which is essential for industrial applications.

One of the most remarkable aspects of these techniques is their ability to produce intricate geometries that would be impossible to achieve with older methods. This flexibility enables designers and engineers to create custom gratings tailored to specific wavelengths or applications, enhancing functionality and efficiency.

Applications in Industry

lightweight grating

The implications of lightweight grating technology span various sectors. In telecommunications, for example, lightweight optical components are crucial for developing fast and efficient networks. By utilizing lightweight gratings in wavelength division multiplexing systems, data can be transmitted more effectively, leading to faster internet speeds and improved overall performance.

In the field of spectroscopy, portable spectrometers equipped with lightweight gratings facilitate on-site analysis in fields such as environmental monitoring, food safety, and pharmaceuticals. These compact devices allow for rapid measurements without the need for bulky laboratory equipment, making it easier to gather data in remote locations or during field studies.

Furthermore, the integration of lightweight gratings into consumer electronics—such as smartphones and augmented reality devices—opens possibilities for advanced imaging systems. As these devices become increasingly sophisticated, lightweight optics play an essential role in enhancing visual quality while minimizing weight and size.

Challenges and Future Directions

Despite the numerous advantages of lightweight grating technology, challenges remain. The optical properties of lightweight materials must match or exceed those of traditional components to ensure that performance standards are maintained. Research is ongoing to address issues related to light scattering, thermal stability, and long-term durability.

Furthermore, as industries continue to evolve towards more sustainable practices, the development of eco-friendly materials for lightweight gratings is becoming critical. Innovations in biodegradable polymers and recyclable composites could pave the way for a more sustainable future in optics.

Conclusion

Lightweight grating represents a significant stride forward in optical technology, providing solutions to long-standing challenges associated with traditional diffraction gratings. Its myriad applications across various industries highlight its transformative potential, from enhancing telecommunications to enabling portable spectroscopic analysis. As research progresses and manufacturing techniques improve, the future of lightweight grating is poised to reshape our interaction with light and advance many technological frontiers. Embracing this innovation will lead not only to enhanced optical devices but also to a more connected and capable world.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025