- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

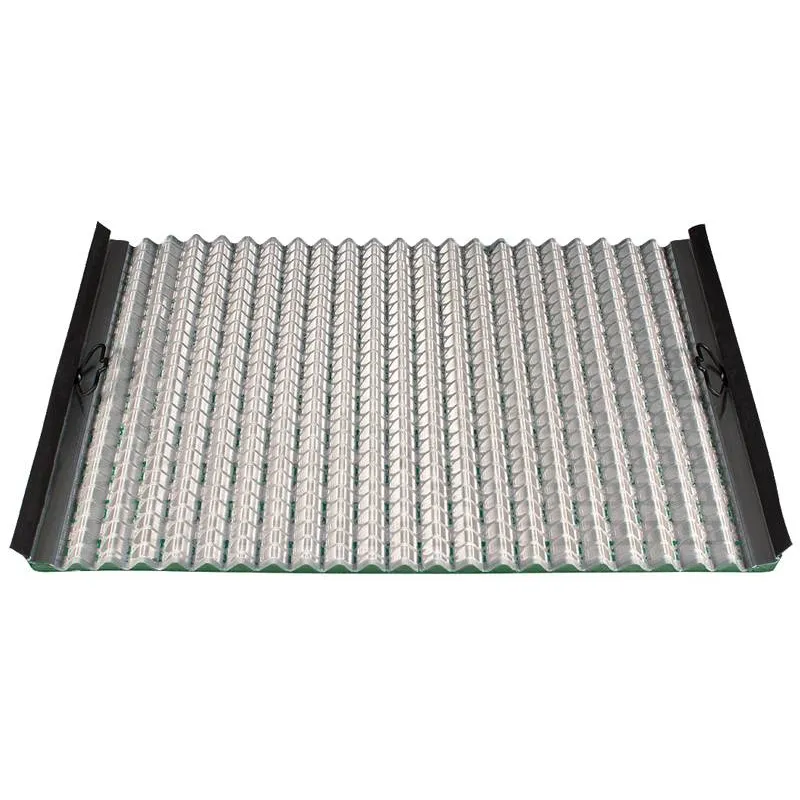

Durable Steel Grating Solutions for Industrial Applications and Heavy Load Requirements

The Advantages of Heavy-Duty Steel Grating

Heavy-duty steel grating has become an essential component in a range of industrial and commercial applications. Known for its robustness and durability, this type of grating is predominantly used in environments that require a reliable and strong flooring solution. In this article, we will explore the advantages of heavy-duty steel grating, its applications, and factors to consider when selecting the right grating for a specific project.

Understanding Heavy-Duty Steel Grating

Heavy-duty steel grating is manufactured from high-quality steel with thick bars, providing superior strength and load-bearing capacity compared to regular grating options. It is typically produced through a process of forging, where steel bars are welded into a grid-like pattern, creating a series of slots that allow for efficient drainage and airflow. This construction method enhances the grating's resistance to wear and tear, making it ideal for heavy loads and extreme conditions.

Advantages of Heavy-Duty Steel Grating

1. Strength and Durability One of the primary advantages of heavy-duty steel grating is its exceptional strength. The robust design can support significant weights, making it suitable for heavy machinery, vehicle traffic, and industrial processes. This durability translates into a long lifespan, reducing the need for frequent replacements.

2. Safety Features Safety is a critical consideration in industrial environments. Heavy-duty steel grating typically offers slip-resistant surfaces, reducing the risk of accidents associated with slipping. Additionally, the open design allows for easy visibility and drainage, minimizing hazards associated with pooling liquids.

3. Versatility Heavy-duty steel grating can be utilized in various applications, from walkways and platforms to trench covers and grating for HVAC systems. Its versatility extends across sectors including manufacturing, petrochemical, construction, and waste management. This adaptability makes it a preferred choice for many projects requiring a reliable flooring solution.

4. Cost-Effectiveness While the initial investment in heavy-duty steel grating might be higher than lighter alternatives, its longevity and low maintenance requirements result in lower overall costs. Businesses can save significantly by reducing repair and replacement expenses over time.

5. Ease of Installation Heavy-duty steel grating is designed for easy installation. The pre-fabricated panels can be quickly assembled on-site, facilitating efficient project timelines. Additionally, due to its lightweight nature compared to concrete solutions, it can be transported and maneuvered with relative ease.

6. Customizability Heavy-duty steel grating can be customized to meet specific project requirements. Various bar sizes, spacing options, and surface treatments (such as galvanization or powder coating) can be provided, allowing for tailored solutions that fit specific needs and aesthetic preferences.

heavy duty steel grating

Applications of Heavy-Duty Steel Grating

Heavy-duty steel grating is utilized in numerous applications, including

- Industrial Flooring Used in factories and warehouses to provide a stable surface for machinery and workers. - Catwalks and Walkways Providing safe passages for personnel in environments where slip-resistance is crucial. - Drains and Trench Covers Allowing for efficient water management while supporting vehicular traffic loads. - Platform and Support Structures Offering a reliable foundation for heavy equipment and storage.

Selecting the Right Heavy-Duty Steel Grating

When choosing heavy-duty steel grating, several factors should be considered to ensure optimal performance

1. Load Capacity Understanding the load requirements is crucial. It is important to choose a grating design that can safely accommodate the expected weights. 2. Environmental Conditions Consider factors such as exposure to chemicals, moisture, and temperature fluctuations, as these can affect the longevity and performance of the grating.

3. Safety Features Depending on the application, selecting grating with adequate slip resistance is essential for preventing accidents.

4. Aesthetic Requirements If the installation area is visible to clients or the public, aesthetic considerations may also come into play. Options such as powder coating can improve the appearance while providing additional corrosion resistance.

5. Compliance and Standards Ensure that the selected grating meets relevant industry standards and regulations for safety and performance.

Conclusion

Heavy-duty steel grating offers a multitude of advantages, including strength, durability, slip resistance, and versatility. Its applications span a variety of industries, making it a critical component for safe and efficient operations. By carefully considering specific project requirements and environmental conditions, businesses and contractors can select the most suitable heavy-duty grating solution, ultimately leading to enhanced safety and performance in their operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025