- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 19, 2025 05:09

Back to list

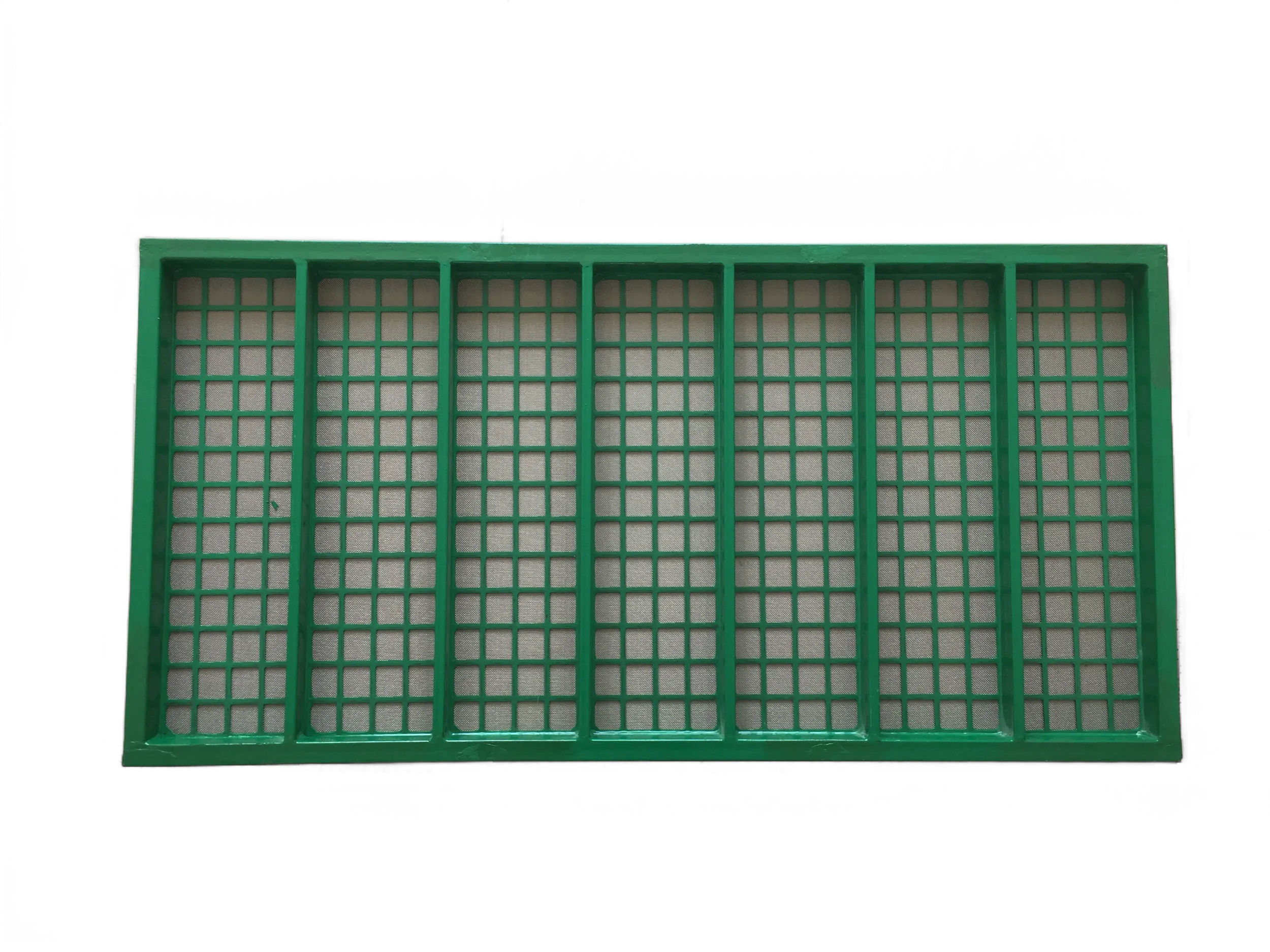

heavy-duty welded bar grating

Heavy-duty welded bar grating stands as a pinnacle of strength and versatility in industrial flooring and structural element design. This robust product is crafted by the fusion of cross bars and bearing bars. The process involves intense pressure welding, ensuring that the structure not only holds up under significant weight but also retains its integrity over extended periods and in challenging environments.

Ease of installation and adaptability further enhance the appeal of heavy-duty welded bar grating. Available in a variety of sizes, configurations, and bar depths, these gratings can be customized to fit specific spatial constraints and design requirements. Whether for new construction projects or retrofitting existing installations, they provide a straightforward solution that saves time and labor costs. Since the panels can often be cut on-site and adjusted as needed, the implementation of this product is streamlined and efficient. Professionals within engineering and architecture repeatedly acclaim the aesthetic and functional benefits of heavy-duty welded bar grating. Its clean lines and industrial aesthetic not only perform functionally but elevate the design of projects by adding a modern, orderly appearance which complements contemporary architectural styles. The integration of these gratings can transform utilitarian areas into spaces that also offer visual appeal. Reliability is a key component when considering the procurement of heavy-duty welded bar grating. Sourced from reputable manufacturers who pride themselves on delivering products meeting stringent quality controls, these gratings offer unmatched confidence in performance. With industry certifications and compliance to international manufacturing standards, procurement decisions are backed by significant authority and credibility. In conclusion, heavy-duty welded bar grating is more than just a grid of metal—it’s an investment in safety, longevity, and design. With a proven track record of performance in some of the toughest industries, it's a choice that offers peace of mind alongside economic and operational efficiencies. For organizations looking to incorporate a product that balances functionality with aesthetic appeal, heavy-duty welded bar grating presents an unparalleled solution. In an ever-evolving industrial landscape, this grating continues to meet demands for robust and dependable flooring systems, creating pathways towards safer and more reliable infrastructure.

Ease of installation and adaptability further enhance the appeal of heavy-duty welded bar grating. Available in a variety of sizes, configurations, and bar depths, these gratings can be customized to fit specific spatial constraints and design requirements. Whether for new construction projects or retrofitting existing installations, they provide a straightforward solution that saves time and labor costs. Since the panels can often be cut on-site and adjusted as needed, the implementation of this product is streamlined and efficient. Professionals within engineering and architecture repeatedly acclaim the aesthetic and functional benefits of heavy-duty welded bar grating. Its clean lines and industrial aesthetic not only perform functionally but elevate the design of projects by adding a modern, orderly appearance which complements contemporary architectural styles. The integration of these gratings can transform utilitarian areas into spaces that also offer visual appeal. Reliability is a key component when considering the procurement of heavy-duty welded bar grating. Sourced from reputable manufacturers who pride themselves on delivering products meeting stringent quality controls, these gratings offer unmatched confidence in performance. With industry certifications and compliance to international manufacturing standards, procurement decisions are backed by significant authority and credibility. In conclusion, heavy-duty welded bar grating is more than just a grid of metal—it’s an investment in safety, longevity, and design. With a proven track record of performance in some of the toughest industries, it's a choice that offers peace of mind alongside economic and operational efficiencies. For organizations looking to incorporate a product that balances functionality with aesthetic appeal, heavy-duty welded bar grating presents an unparalleled solution. In an ever-evolving industrial landscape, this grating continues to meet demands for robust and dependable flooring systems, creating pathways towards safer and more reliable infrastructure.

Share

Prev:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025