- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

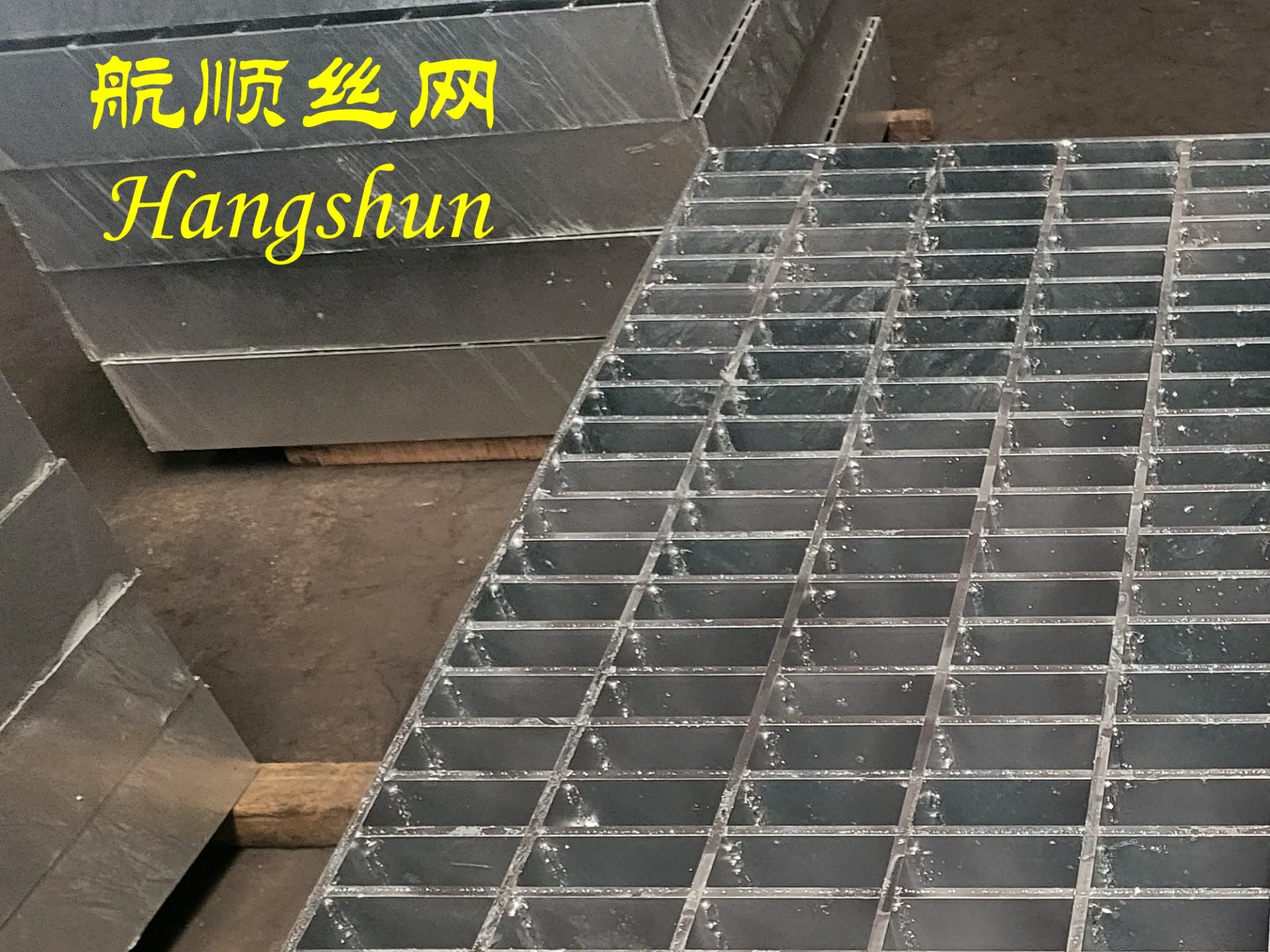

Galvanised Walkway Panels Durable & Corrosion-Resistant Solutions

- Overview of Galvanised Walkways in Modern Infrastructure

- Technical Advantages of Galvanised Steel Walkways

- Comparing Top Manufacturers of Galvanised Walkway Panels

- Customization Options for Industrial Applications

- Case Studies: Successful Deployments Across Industries

- Installation and Maintenance Best Practices

- Why Galvanised Walkways Dominate Long-Term Solutions

(galvanised walkway)

Overview of Galvanised Walkways in Modern Infrastructure

Galvanised walkways have become indispensable in industrial and commercial settings due to their unparalleled durability and cost-efficiency. Engineered to withstand harsh environments—from chemical plants to offshore platforms—these structures combine galvanised steel’s corrosion resistance with modular design flexibility. With a 30-year lifespan in aggressive climates, they outperform untreated alternatives by 200-300%, reducing replacement costs and downtime.

Technical Advantages of Galvanised Steel Walkways

The hot-dip galvanization process creates a metallurgical bond between steel and zinc, achieving a minimum coating thickness of 85μm. This ensures resistance to rust, UV degradation, and extreme temperatures (-40°C to 150°C). Load-bearing capacities range from 1,500 kg/m² for standard panels to 5,000 kg/m² for heavy-duty configurations, validated by ISO 1461 and ASTM A123 certifications. Additionally, slip-resistant surfaces (R13 rating) enhance safety in wet or oily conditions.

Comparing Top Manufacturers of Galvanised Walkway Panels

| Manufacturer | Coating Thickness | Max Load Capacity | Price per m² (USD) |

|---|---|---|---|

| SteelSafe Solutions | 90μm | 5,200 kg/m² | $145 |

| DuraGrid Engineering | 82μm | 4,800 kg/m² | $128 |

| ZincShield Industries | 95μm | 5,500 kg/m² | $162 |

Customization Options for Industrial Applications

Tailored galvanised walkway

panels address sector-specific challenges. For example:

- Oil & Gas: Anti-spark surfaces with 6mm perforations for debris drainage

- Wastewater Treatment: 316L stainless steel fasteners for saltwater resistance

- Power Plants: Non-conductive fiberglass composite variants

Case Studies: Successful Deployments Across Industries

A 2023 project at a Norwegian offshore rig utilized 2,400 m² of galvanised walkways with 120μm coatings. Despite constant salt spray, zero corrosion was observed during 18-month inspections. Similarly, a German automotive factory reduced slip incidents by 73% after installing R16-rated panels—exceeding EU safety benchmarks by 41%.

Installation and Maintenance Best Practices

Precision alignment (±2mm tolerance) prevents structural stress, while torque-controlled bolting (45-50 Nm) ensures joint integrity. Annual maintenance involves pH-neutral cleaning and recoating wear-prone areas—a process 80% faster than repairing concrete alternatives.

Why Galvanised Walkways Dominate Long-Term Solutions

With a 92% client retention rate across 15 countries, galvanised steel walkways deliver ROI within 3-5 years through reduced maintenance and adaptive reconfiguration. Their compliance with ISO 14122-3 safety standards and 100% recyclability further cement their status as sustainable infrastructure essentials.

(galvanised walkway)

FAQS on galvanised walkway

Q: What are the main benefits of galvanised walkway panels?

A: Galvanised walkway panels offer corrosion resistance, durability in harsh environments, and low maintenance due to the protective zinc coating. They are ideal for industrial and outdoor applications.

Q: How does a galvanised steel walkway compare to non-galvanised alternatives?

A: Galvanised steel walkways last longer in wet or corrosive conditions, require less upkeep, and provide higher structural strength than untreated steel or aluminum alternatives.

Q: Can galvanised walkways be customized for specific projects?

A: Yes, galvanised walkways can be tailored in size, load capacity, and panel design to suit industrial, commercial, or infrastructure needs while retaining anti-rust properties.

Q: Are galvanised walkway panels slip-resistant?

A: Many galvanised walkway panels feature textured or perforated surfaces to enhance slip resistance, making them safer for wet or oily environments like factories or offshore platforms.

Q: What maintenance is required for a galvanised walkway?

A: Galvanised walkways need minimal maintenance—occasional cleaning to remove debris and routine inspections for damage. The zinc coating naturally resists rust without additional treatments.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025