- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

CWC Pipe Coating Solutions for Enhanced Durability and Protection of Infrastructure Systems

The Importance of CWC Pipe Coating in Industrial Applications

In today’s industrial landscape, the integrity and longevity of pipelines are paramount. Many sectors, including oil and gas, water treatment, and chemical manufacturing, rely on extensive piping systems to transport fluids safely and efficiently. One of the key technologies developed to enhance the performance of these systems is CWC (Cold Water Cured) pipe coating. This innovative solution plays a critical role in protecting pipes from various environmental and chemical stresses, thereby extending their service life and reducing maintenance costs.

Understanding CWC Pipe Coating

CWC pipe coating refers to a specialized coating process that involves applying a protective layer to pipelines. Unlike traditional coatings that require high-temperature curing processes, CWC technology cures at ambient temperatures. This method not only speeds up the application but also minimizes energy costs, making it a cost-effective choice for many industries.

The main materials used in CWC coatings typically include epoxy, polyurethane, and other polymer-based compounds. These materials are chosen for their exceptional adhesion properties and resistance to corrosion, abrasion, and chemicals. The coatings can be customized to suit specific environmental conditions, ensuring that pipelines remain protected even in the most challenging environments.

Benefits of CWC Pipe Coating

1. Corrosion Resistance One of the most significant benefits of CWC pipe coatings is their ability to resist corrosion. Pipelines are often exposed to moisture, soil, and various chemicals that can lead to degradation over time. CWC coatings act as a barrier, preventing corrosive substances from coming into direct contact with the pipe material. This is especially important in regions with high humidity or where pipelines are buried in soil with high salinity.

cwc pipe coating

2. Improved Durability CWC coatings enhance the physical durability of pipes. They provide a tough outer layer that safeguards against mechanical wear and tear, impacts, and environmental factors. This increased durability helps to reduce the frequency of repairs and replacements, leading to substantial cost savings for companies.

3. Environmental Protection By extending the life of pipelines, CWC coatings contribute to environmental sustainability. Leaks from corroded pipes can lead to significant environmental disasters, affecting water supplies, ecosystems, and communities. The use of high-quality coatings helps to minimize the risk of leaks, ensuring that industrial operations are not just efficient but also environmentally responsible.

4. Ease of Application The cold curing process associated with CWC coatings allows for application in various weather conditions, including cold temperatures. This flexibility means that projects can proceed without delays caused by unfavorable conditions, facilitating quicker installation and reduced downtime for essential infrastructure.

5. Cost-Effectiveness While the initial investment in CWC coating technology might be higher than traditional methods, the long-term savings are undeniable. Reduced maintenance, extended lifespan of pipelines, and lower risk of environmental fines all contribute to a strong return on investment. Companies can allocate saved resources towards other critical areas, enhancing overall operational efficiency.

Conclusion

In conclusion, CWC pipe coating represents a significant advancement in the field of pipeline protection. As industries face increasing challenges related to corrosion, environmental regulations, and maintenance costs, investing in robust solutions like CWC coatings is essential. The benefits of enhanced corrosion resistance, improved durability, environmental protection, ease of application, and overall cost-effectiveness make CWC pipe coating an attractive option for businesses looking to safeguard their infrastructure.

As we move towards a more sustainable and responsible industrial future, technologies like CWC coating will play a crucial role in ensuring that our piping systems remain safe, efficient, and environmentally sound. By understanding and utilizing CWC coatings, industries can not only protect their assets but also contribute positively to the global environment, fostering a commitment to sustainability in all operational practices.

-

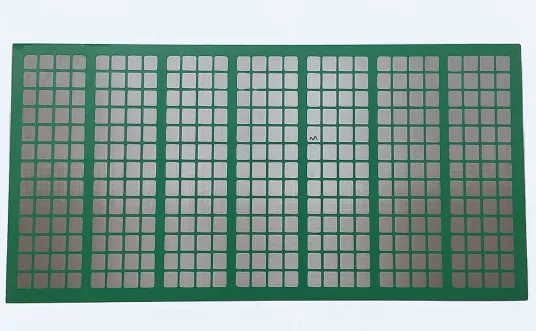

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025