- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mar . 07, 2025 02:01

Back to list

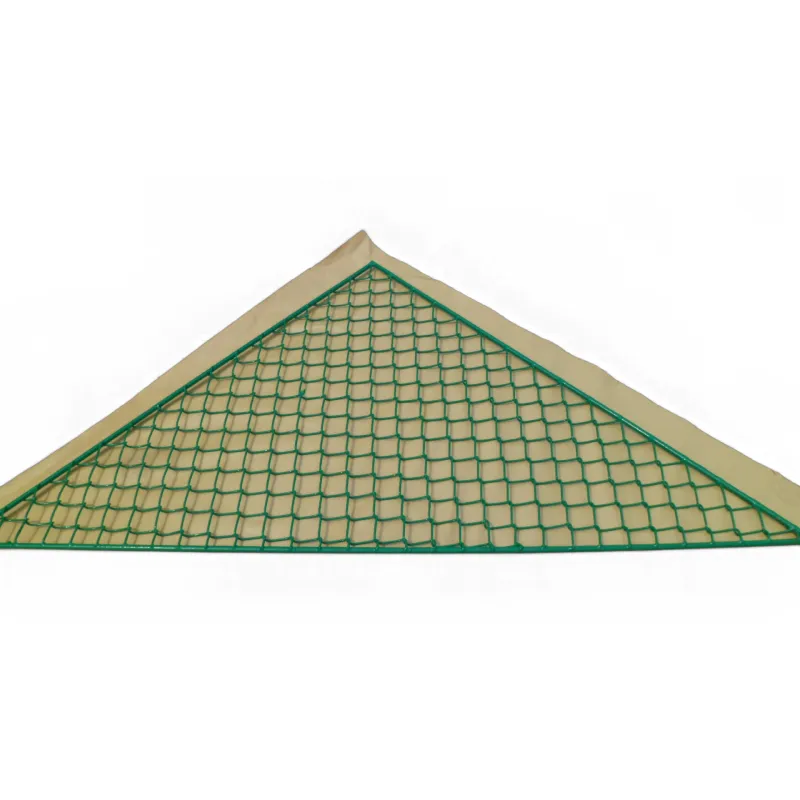

open floor grating

Open floor grating, a pivotal component in industrial and architectural settings, serves as both a functional and aesthetic solution for various flooring needs. The importance of selecting the appropriate open floor grating lies in its ability to provide durability, safety, and cost-effectiveness in high-traffic and demanding environments.

The authority in understanding open floor grating also comes from knowing industry standards and regulatory requirements. Compliance with health and safety standards is non-negotiable. The American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) regulations provide comprehensive guidelines that govern the manufacturing and usage of these gratings, ensuring they meet the required load-bearing capacities and anti-slip properties. Adherence to these standards is not just a matter of legal compliance but also a testament to a commitment to quality and safety. Building trustworthiness, our hands-on analysis and assessment of open floor grating installations reflect on its longevity and return on investment. Clients report significant reductions in maintenance costs and operational disruptions, thanks to the durability of high-quality gratings. Furthermore, the integration of anti-slip surfaces has drastically mitigated workplace accidents, a sentiment echoed across various case studies and industry feedback. These tangible benefits underscore the value proposition of investing in premium-grade grating solutions. In conclusion, open floor grating transcends its basic functional role to become a crucial element in optimizing workplace efficiency and safety. Its selection and implementation require a blend of experience, expertise, authority, and trustworthiness to maximize its benefits. By choosing the right grating, industries not only enhance operational flows but also safeguard their most valuable assets—their personnel. Consequently, understanding the nuances of open floor grating is not just an investment in infrastructure but a commitment to excellence in operational standards.

The authority in understanding open floor grating also comes from knowing industry standards and regulatory requirements. Compliance with health and safety standards is non-negotiable. The American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) regulations provide comprehensive guidelines that govern the manufacturing and usage of these gratings, ensuring they meet the required load-bearing capacities and anti-slip properties. Adherence to these standards is not just a matter of legal compliance but also a testament to a commitment to quality and safety. Building trustworthiness, our hands-on analysis and assessment of open floor grating installations reflect on its longevity and return on investment. Clients report significant reductions in maintenance costs and operational disruptions, thanks to the durability of high-quality gratings. Furthermore, the integration of anti-slip surfaces has drastically mitigated workplace accidents, a sentiment echoed across various case studies and industry feedback. These tangible benefits underscore the value proposition of investing in premium-grade grating solutions. In conclusion, open floor grating transcends its basic functional role to become a crucial element in optimizing workplace efficiency and safety. Its selection and implementation require a blend of experience, expertise, authority, and trustworthiness to maximize its benefits. By choosing the right grating, industries not only enhance operational flows but also safeguard their most valuable assets—their personnel. Consequently, understanding the nuances of open floor grating is not just an investment in infrastructure but a commitment to excellence in operational standards.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025