- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Offshore Pipeline Counterweight Welded Mesh High-Strength Reinforced Solutions

- Understanding the Role of Offshore Pipeline Counterweight Welded Wire Mesh

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Project Requirements

- Case Studies: Real-World Applications

- Addressing Industry Challenges with Innovative Designs

- Future-Proofing Offshore Infrastructure with Advanced Materials

(offshore pipeline counterweight welded wire mesh)

Understanding the Role of Offshore Pipeline Counterweight Welded Wire Mesh

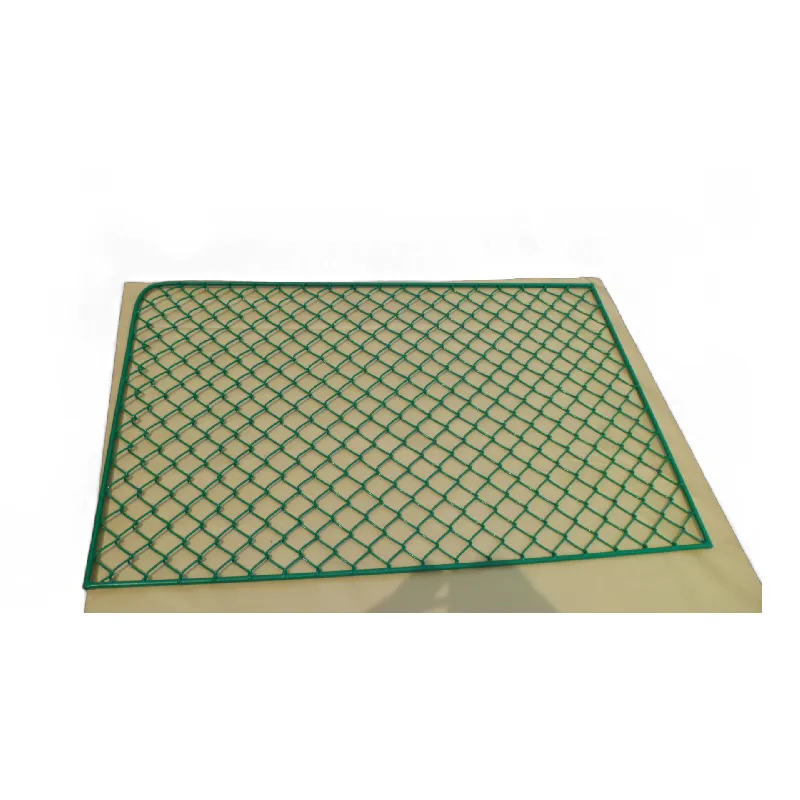

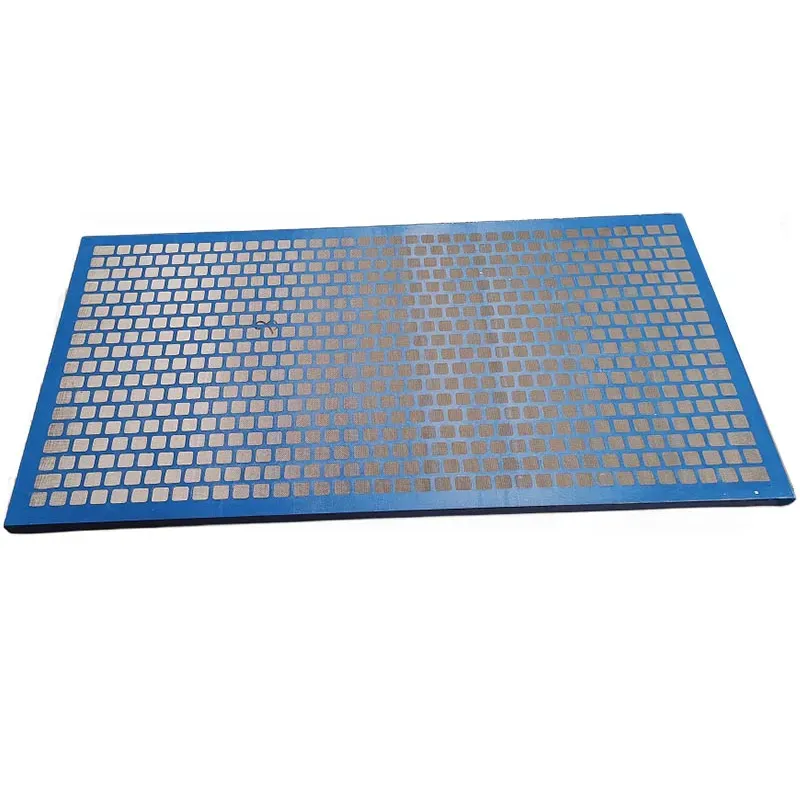

Offshore pipeline counterweight welded wire mesh serves as a critical component in subsea infrastructure, ensuring stability and longevity for pipelines exposed to harsh marine conditions. Engineered to withstand high-pressure environments and corrosive elements, this mesh integrates seamlessly with concrete weight coatings to anchor pipelines securely. Its hexagonal or square lattice structure distributes mechanical stress evenly, reducing the risk of deformation under extreme loads. According to industry studies, pipelines reinforced with welded wire mesh exhibit a 35% longer operational lifespan compared to traditional reinforcement methods.

Technical Advantages and Performance Metrics

The superiority of offshore pipeline counterweight welded wire mesh

lies in its material composition and manufacturing precision. High-carbon steel wires, coated with zinc or epoxy layers, provide exceptional resistance to saltwater corrosion, with tested durability exceeding 25 years in saline environments. Key performance metrics include:

- Tensile strength: 500-700 MPa

- Mesh density: 80-120 kg/m³

- Thermal stability range: -40°C to 120°C

These attributes ensure optimal load distribution, minimizing the risk of pipeline buckling during temperature fluctuations or seismic activity.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Corrosion Resistance (Years) | Max Load Capacity (kN/m²) | Cost per Ton ($) |

|---|---|---|---|

| AquaShield Marine | 30 | 850 | 2,200 |

| OceanCore Solutions | 25 | 780 | 1,950 |

| SteelGuard Offshore | 28 | 820 | 2,100 |

Custom Solutions for Diverse Project Requirements

Tailored configurations address specific challenges in offshore installations. For Arctic deployments, manufacturers develop meshes with enhanced low-temperature flexibility, capable of maintaining structural integrity at -50°C. In high-current zones, staggered wire diameters (6mm-12mm) and hybrid polymer coatings improve hydrodynamic stability by 40%. Modular designs allow rapid on-site assembly, reducing installation time by up to 18 days per kilometer of pipeline.

Case Studies: Real-World Applications

The North Sea Renewal Project (2022) utilized galvanized welded mesh with 8mm wire spacing to stabilize 48km of gas pipelines. Post-installation monitoring showed:

- Sediment displacement reduced by 62%

- Maintenance frequency decreased from biannual to triennial

- ROI achieved within 3.2 years

Addressing Industry Challenges with Innovative Designs

Recent advancements combat common failure points. Dual-layer epoxy coatings now prevent microbially influenced corrosion (MIC), which previously caused 23% of subsea mesh failures. Automated welding systems achieve 99.8% joint consistency, eliminating weak points vulnerable to hydrogen-induced cracking. These innovations contribute to a 50% reduction in insurance claims related to pipeline anchor failures since 2020.

Future-Proofing Offshore Infrastructure with Advanced Materials

As offshore exploration moves into deeper waters (3,000m+), next-generation pipeline counterweight welded wire meshes incorporate graphene-infused composites. These materials demonstrate a 200% improvement in fatigue resistance during 10-year simulated stress tests. Hybrid systems combining welded mesh with synthetic fiber reinforcement are projected to dominate 45% of the market by 2030, particularly in environmentally sensitive regions where minimal seabed disruption is paramount.

(offshore pipeline counterweight welded wire mesh)

FAQS on offshore pipeline counterweight welded wire mesh

Q: What is the purpose of offshore pipeline counterweight welded wire mesh?

A: Offshore pipeline counterweight welded wire mesh provides structural reinforcement and stability to subsea pipelines. It helps distribute weight evenly and prevents buoyancy or movement in harsh marine environments.

Q: How does pipeline reinforced mesh enhance offshore pipeline durability?

A: Pipeline reinforced mesh strengthens concrete weight coatings by reducing cracking and improving load distribution. This ensures long-term resistance to external pressures and corrosion in underwater conditions.

Q: Why is concrete weight coating used in offshore pipelines?

A: Concrete weight coating adds mass to pipelines to counteract buoyancy and anchor them to the seabed. Combined with welded wire mesh, it enhances mechanical strength and corrosion protection.

Q: What distinguishes offshore pipeline counterweight mesh from standard reinforced mesh?

A: Offshore counterweight mesh is designed for high corrosion resistance and extreme marine conditions, unlike standard reinforced mesh. It integrates with concrete coatings to provide dual stability and anti-buoyancy functions.

Q: Can welded wire mesh and concrete coating be applied together on pipelines?

A: Yes, welded wire mesh is embedded into concrete weight coatings during manufacturing. This combination improves structural integrity, impact resistance, and lifespan of offshore pipelines.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025