- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 25, 2025 23:42

Back to list

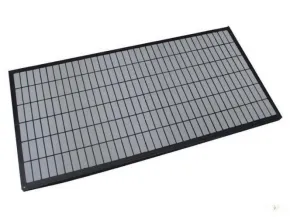

steel walkway mesh

In the realm of construction and industrial design, mild steel walkway mesh serves as a testament to versatility and functionality. This construction component is often favoured for its resilience and adaptability across different projects. It has become a staple for engineers and architects who strive to blend safety with design efficiency.

Trustworthiness and Long-Term Benefits Building trust in mild steel walkway mesh as a reliable construction commodity stems from its proven track record in real-world applications. Users frequently report its longevity and minimal maintenance needs as standout benefits. For instance, a pertinent example includes its use in high-traffic urban installations where routine upkeep might pose logistical challenges. Here, the low maintenance requirement complements modern demands for cost-efficient architectural solutions. This financial prudence, paired with its robust performance, reinforces trust in mild steel mesh as a preferable option over alternative materials like aluminum or plastic composites. Environmental Considerations and Sustainability In an era where sustainability dictates construction practices, mild steel's recyclability presents a significant advantage. The material can be easily repurposed and reformed into new components, supporting sustainable construction initiatives. This property not only lowers the environmental footprint of projects but also aligns with the growing demand for eco-friendly building solutions. Companies invested in green building certifications such as LEED (Leadership in Energy and Environmental Design) often prefer mild steel due to its ability to integrate seamlessly within such frameworks. Conclusion The strategic use of mild steel walkway mesh in construction projects is not only a reflection of its practical benefits but also an endorsement of quality over quantity in material selection. Its distinctive properties enhance safety, longevity, and structural efficiency, making it a staple in the toolkit of seasoned construction professionals. As the sector evolves, the emphasis on such high-performing materials will definitely intensify, bolstering projects that prioritize both aesthetic value and engineering sophistication.

Trustworthiness and Long-Term Benefits Building trust in mild steel walkway mesh as a reliable construction commodity stems from its proven track record in real-world applications. Users frequently report its longevity and minimal maintenance needs as standout benefits. For instance, a pertinent example includes its use in high-traffic urban installations where routine upkeep might pose logistical challenges. Here, the low maintenance requirement complements modern demands for cost-efficient architectural solutions. This financial prudence, paired with its robust performance, reinforces trust in mild steel mesh as a preferable option over alternative materials like aluminum or plastic composites. Environmental Considerations and Sustainability In an era where sustainability dictates construction practices, mild steel's recyclability presents a significant advantage. The material can be easily repurposed and reformed into new components, supporting sustainable construction initiatives. This property not only lowers the environmental footprint of projects but also aligns with the growing demand for eco-friendly building solutions. Companies invested in green building certifications such as LEED (Leadership in Energy and Environmental Design) often prefer mild steel due to its ability to integrate seamlessly within such frameworks. Conclusion The strategic use of mild steel walkway mesh in construction projects is not only a reflection of its practical benefits but also an endorsement of quality over quantity in material selection. Its distinctive properties enhance safety, longevity, and structural efficiency, making it a staple in the toolkit of seasoned construction professionals. As the sector evolves, the emphasis on such high-performing materials will definitely intensify, bolstering projects that prioritize both aesthetic value and engineering sophistication.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025