- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

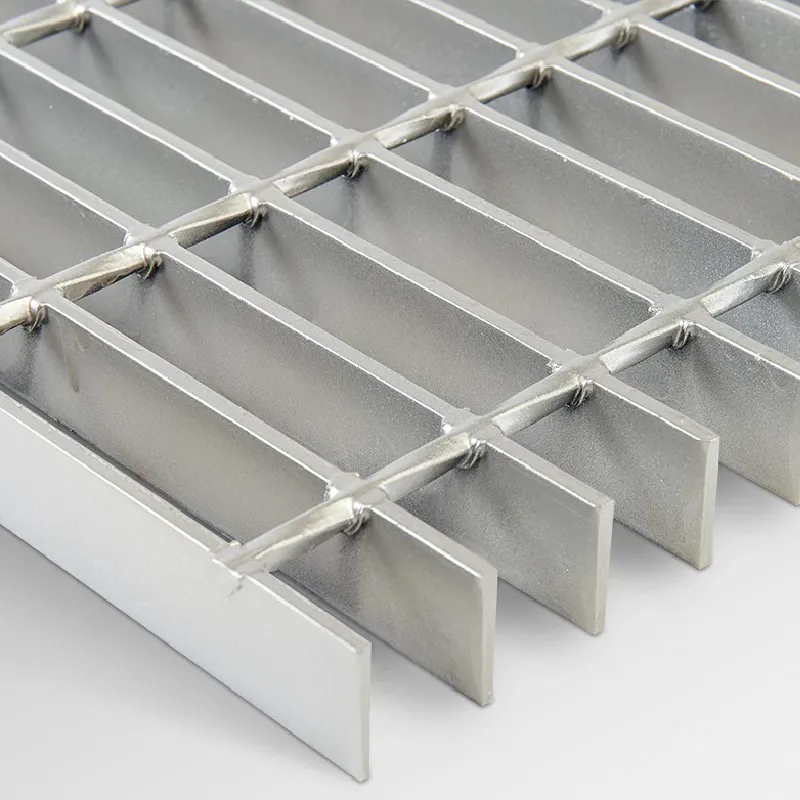

banded bar grating

Understanding Banded Bar Grating An Overview

Banded bar grating, a type of engineered material used in various industrial and architectural applications, has gained prominence due to its unique combination of strength, durability, and aesthetic appeal. This innovative structure consists of a grid-like pattern formed by interwoven bars that offer not only functional benefits but also visual considerations in design.

The Composition and Structure

Banded bar grating is typically made from metals such as steel or aluminum, though fiberglass variants exist for specific applications. The composition of the bars, which can vary in thickness and spacing, is crucial for determining the load-bearing capacity and overall performance of the grating. The banding adds an extra layer of strength, often aligning vertically or horizontally to create a robust system that can support heavy loads while remaining easy to navigate.

The intrinsic design allows for flexibility in applications. Due to its modular nature, designers can create custom sizes and configurations, catering to specific requirements across various sectors, including construction, transportation, and manufacturing. The lightweight nature of the grating, combined with its high strength-to-weight ratio, makes it an ideal choice for walkways, platforms, and drainage covers.

Applications in Industry and Architecture

In industrial settings, banded bar grating is utilized extensively for walkways and platforms. Its slip-resistant surface significantly reduces the risk of accidents, which is crucial in environments where safety is paramount. Additionally, the open design allows for drainage and ventilation, making it suitable for water treatment plants, chemical processing facilities, and other sectors where spills or exposure to corrosive substances are common.

banded bar grating

Architecturally, banded bar grating has become a favored choice due to its modern aesthetic appeal. Designers often incorporate it into building facades and decorative elements, as the interplay of light and shadows through the grating adds a dynamic quality to structures. Moreover, the material can be coated or painted to suit various design themes, enhancing its versatility as a design element.

Advantages of Using Banded Bar Grating

One of the primary benefits of banded bar grating is its strength. The design inherently distributes weight across its surface, allowing for the support of heavy machinery and pedestrian traffic without compromising safety. Additionally, maintenance is relatively low; the durable materials resist corrosion and damage from environmental factors, extending the lifespan significantly compared to traditional materials.

Another advantage is the ease of installation. Banded bar grating can be easily cut to size and fitted into various frameworks, reducing labor costs and installation time. This flexibility is particularly beneficial in retrofitting existing structures where precise measurements are crucial.

Conclusion

Banded bar grating presents a unique blend of strength, safety, and aesthetic appeal, making it a preferred choice in many industrial and architectural applications. Its ability to support heavy loads while allowing for efficient drainage and airflow not only enhances functionality but also promotes safety in the workplace. As industries continue to evolve, the demand for versatile, durable materials like banded bar grating is likely to grow, leading to further innovations in design and application.

In a world increasingly focused on sustainability and efficiency, banded bar grating stands as a testament to how functional requirements can coexist with creative design, providing solutions that are both practical and visually compelling.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025