- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1 aluminum grating

Understanding 1% Aluminum Grating

When it comes to industrial applications, structural materials play a crucial role in ensuring safety and efficiency. One such material that has gained popularity over the years is aluminum grating. Among various specifications and designs, 1% aluminum grating has emerged as a noteworthy option, particularly in settings that require lightweight but sturdy support systems. In this article, we will delve into the characteristics, advantages, applications, and maintenance of 1% aluminum grating.

What is Aluminum Grating?

Aluminum grating is a type of engineered flooring or roofing material made from aluminum. It consists of a series of parallel bars that are joined together with perpendicular bars, creating a grid-like pattern. This design allows for safe passage while also enabling the efficient flow of light, air, water, and other substances. Aluminum grating is renowned for its durability, resistance to corrosion, and lightweight properties, making it suitable for a variety of applications.

Characteristics of 1% Aluminum Grating

The term 1% aluminum grating typically refers to the amount of alloying elements and impurities allowed in the aluminum used to produce the grating. This specification often refers to the purity level of the aluminum. Higher purity aluminum typically has about 99% aluminum content, while 1% indicates a small percentage of other alloying elements such as manganese, silicon, or magnesium. This minor addition helps improve specific properties such as strength, durability, and resistance to corrosion without significantly compromising the overall lightweight nature of the material.

1% aluminum grating maintains a fine balance between strength and weight. The combination of low density and high tensile strength makes it ideal for structural applications where weight is a critical factor. Furthermore, aluminum grating is often anodized or coated to enhance its resistance to wear and tear, further increasing its lifespan and functionality.

Advantages of Using 1% Aluminum Grating

One of the primary advantages of 1% aluminum grating is its lightweight nature. This allows for easy installation and reduces transport costs when moving materials on-site. Moreover, because aluminum is naturally resistant to corrosion, 1% aluminum grating can withstand harsh environmental conditions without significant degradation. This makes it an excellent choice for outdoor applications or in industries where exposure to chemicals is common.

Another vital advantage is the slip resistance that aluminum grating offers. With various surface finishes available, including serrated patterns, users can select a grating style that minimizes slip risk, thus enhancing safety in pedestrian and vehicular traffic areas.

1 aluminum grating

Additionally, the versatility of aluminum grating allows for customization in shape, size, and design. This adaptability ensures that it can fit into various architectural and structural frameworks, meeting the unique needs of different industries, from aerospace to construction.

Applications

1% aluminum grating finds its use in a wide array of applications. In the construction industry, it is often utilized for walkways, platforms, and stair treads, where safety and structural integrity are paramount. In the industrial sector, it can be found in flooring for machinery, maintenance platforms, and catwalks.

Moreover, in municipal infrastructure, aluminum grating is employed in drainage covers, bridge decks, and ventilation grates. Its lightweight and corrosion-resistant properties make it particularly suitable for these applications, enhancing both functionality and longevity.

Maintenance of 1% Aluminum Grating

While 1% aluminum grating is low maintenance, periodic checks and cleaning can extend its lifespan. Routine cleaning can be achieved using mild detergents and water to remove dirt and debris that could accumulate over time. For more severe corrosion, specialized cleaning solutions may be necessary.

Inspections should focus on identifying any signs of wear, loose fittings, or structural deficiencies. If any damages are noted, prompt repairs or replacements should be undertaken to maintain safety standards.

Conclusion

In summary, 1% aluminum grating represents an exceptional solution for numerous applications across various industries. Its lightweight characteristics, corrosion resistance, slip prevention, and versatility make it an indispensable choice for modern construction and industrial projects. As industries continue to evolve and demand innovative solutions, 1% aluminum grating is well-positioned to meet those needs while ensuring safety and efficiency in a variety of settings. The thoughtful use and maintenance of this material not only enhance structural integrity but also contribute to long-term sustainability in infrastructure development.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

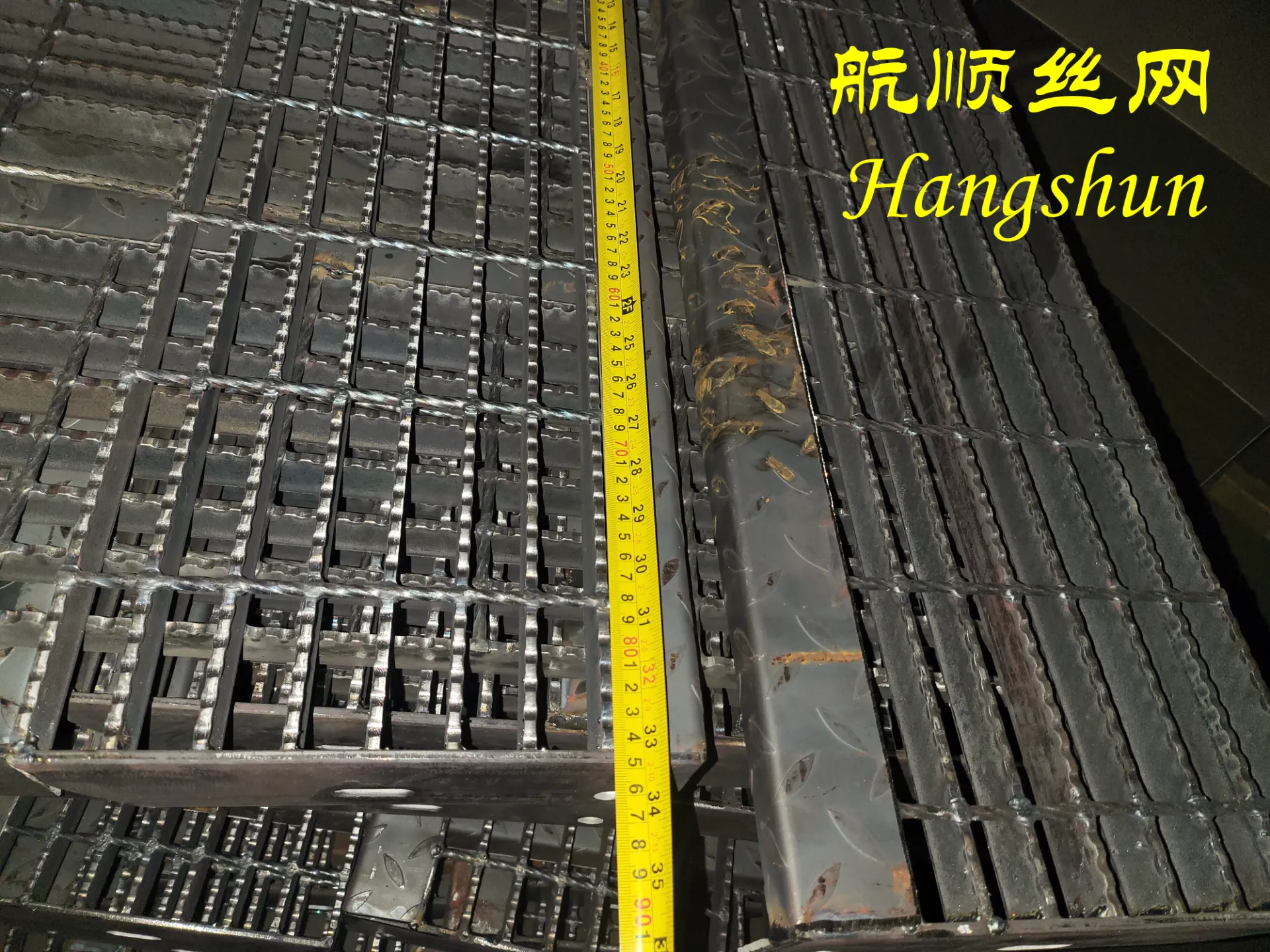

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025