- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Selecting the Right Shale Shaker Screen Mesh for Optimal Performance

Understanding Shale Shaker Screen Mesh Key to Efficient Drilling Operations

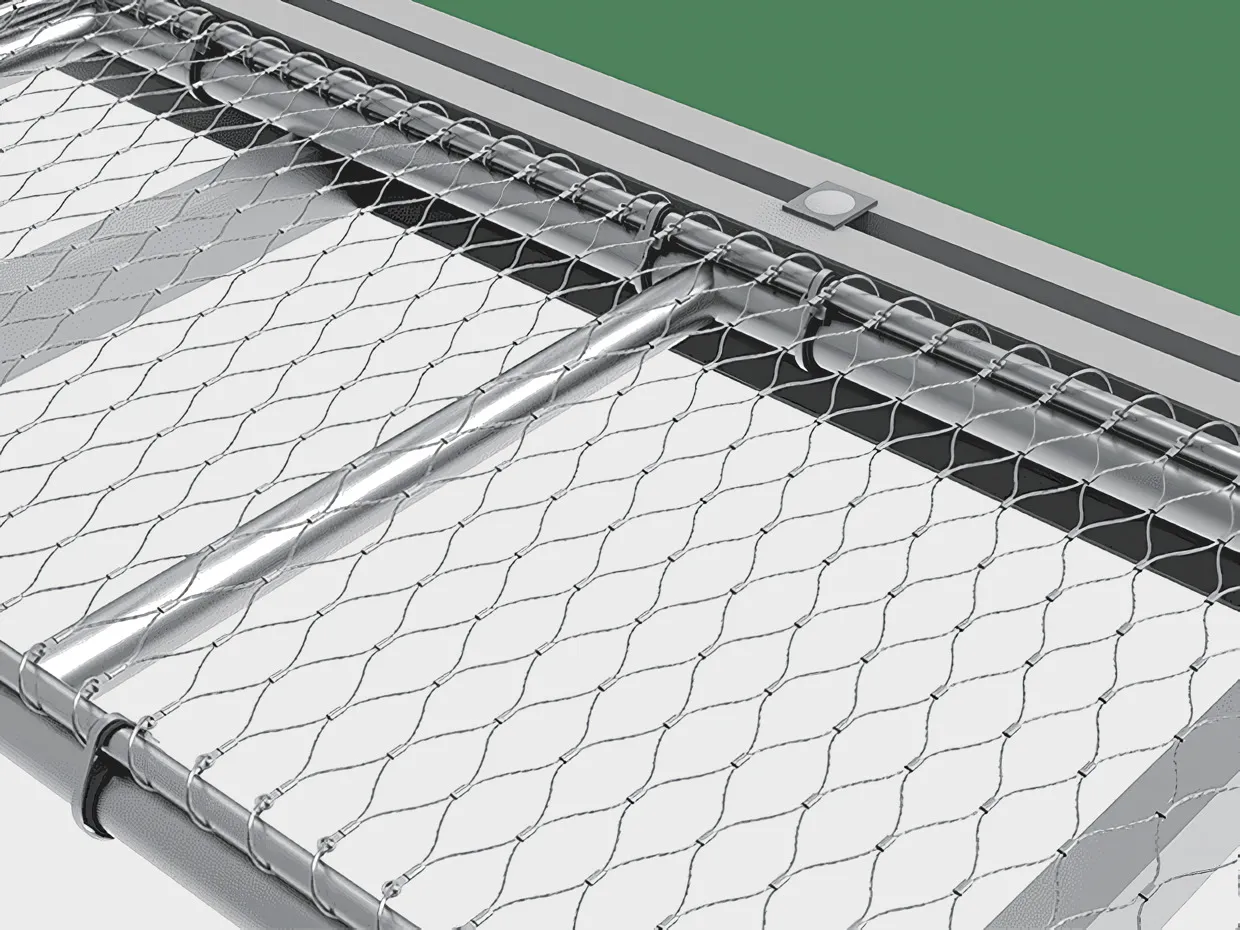

In the oil and gas industry, drilling operations are complex and require precision and efficiency to ensure success. One pivotal element in this process is the shale shaker, which plays a crucial role in the separation of drilling fluids and cuttings. Central to the effectiveness of a shale shaker is the screen mesh, often referred to as shale shaker screen mesh. This article delves into the importance of shale shaker screen mesh, its types, materials, and the factors influencing its performance.

What is Shale Shaker Screen Mesh?

Shale shaker screen mesh serves as a filtering layer that enables the separation of solid particles from liquid drilling fluids. During the drilling process, rock cuttings and debris accumulate in the drilling fluids, which must be removed to maintain the fluid's properties and ensure efficient drilling. The shale shaker utilizes a series of screens to stratify and separate these materials based on their size, allowing the recycling of drilling fluids and minimizing waste.

Types of Shale Shaker Screen Mesh

Shale shaker screens come in various types, classified mainly by their mesh size and configuration. The two most common types are

1. Flat Screens These are the most widely used type of screens. They provide a large surface area for effective separation and can handle a significant volume of drilling fluid. Flat screens can typically be manufactured with multiple layers of mesh, enabling them to filter out different particle sizes effectively.

2. Hook Strip Screens These screens have a reinforced edge that hooks onto the shaker frame, providing better stability and durability. They are particularly useful for high-flow-rate applications, as their design minimizes the likelihood of screen deformation under pressure.

3. Pyramid Screens This modern design has a three-dimensional structure that enhances the separation process. The pyramid shape allows for multiple layers of filtration in a compact design, ensuring high-performance efficiency.

Materials Used in Shale Shaker Screen Mesh

The choice of material is crucial for the durability and effectiveness of shale shaker screens. Common materials include

shale shaker screen mesh

- Wire Mesh Most traditional screens are made from stainless steel or carbon steel wire mesh due to their strength and resistance to corrosion. The choice of mesh type impacts the screen's life expectancy and performance.

- Composite Materials Advanced shale shaker screens are increasingly being made from composite materials. These screens offer enhanced performance, including improved wear resistance and reduced plugging.

- Polymers Some modern screens utilize polymer-based materials, which provide flexibility and can be customized for specific applications. These screens are often lighter, which can reduce operational costs.

Factors Influencing Performance

The performance of shale shaker screen mesh is influenced by several factors

1. Mesh Size The size of the openings in the screen directly affects its filtering ability. A finer mesh captures smaller particles but may lead to increased fluid resistance, while a coarser mesh allows for a higher flow rate at the cost of efficiency in particle removal.

2. Screen Tension Proper tensioning of the screen is essential for effective filtration. If the screen is too loose, it can deform, leading to reduced separation efficiency. Conversely, excessive tension can cause premature wear.

3. Fluid Properties The characteristics of the drilling fluid, including viscosity and solids content, also play a significant role in determining the optimal screen mesh type and configuration.

Conclusion

In summary, shale shaker screen mesh is integral to successful drilling operations in the oil and gas industry. Understanding the various types of screens, materials used, and factors influencing their performance enables operators to optimize drilling efficiency and minimize costs. As technology continues to advance, the development of more effective and durable screen meshes will remain a focal point for improving drilling processes worldwide.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025