- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 06, 2025 06:37

Back to list

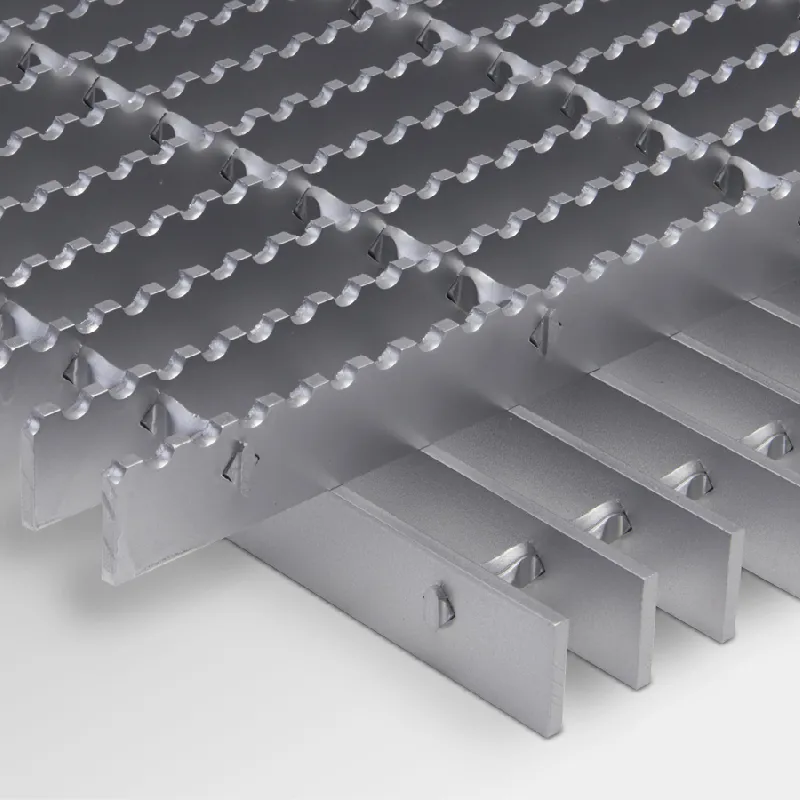

Swage-Locked Steel Grating

Navigating the complex world of metal grating prices can be a daunting task for anyone looking to make an informed purchase decision. As an experienced professional in the field, I understand the nuances that can impact pricing, and I aim to provide you with a comprehensive guide that enhances your purchasing experience by focusing on expertise, authoritativeness, and trustworthiness.

When considering metal grating, the dimensions and load requirements are essential elements that influence cost. Larger panels or those designed to bear heavier loads naturally require more material and stronger manufacturing processes, thereby increasing the price. It's crucial to work with a vendor who can provide detailed specifications to ensure the grating meets your functional requirements without overspending on unnecessary features. Geographic location and market demand also play significant roles in pricing. Grating prices can fluctuate based on regional manufacturing costs, shipping expenses, and local demand levels. For instance, areas with a thriving industrial sector may see higher grating prices due to increased demand, or conversely, lower prices if there are numerous suppliers. Keeping abreast of market trends and developing relationships with local suppliers can help mitigate these costs. Lastly, supplier trustworthiness can impact both the price and quality of the metal grating you purchase. It is imperative to work with suppliers who have established a reputation for reliability and quality in the industry. Look for suppliers who offer certifications for their products and have a track record of compliance with industry standards. An authoritative supplier not only provides high-quality products but also transparent pricing and meticulous customer service, ensuring you get value for your investment. In conclusion, understanding the various elements that impact metal grating prices allows you to make more informed decisions, ensuring safety, functionality, and cost-effectiveness. Whether considering the material type, manufacturing process, or supplier credibility, each aspect is integral to your purchasing experience. With this comprehensive understanding, you can confidently navigate the landscape of metal grating procurement, assured that you are investing in a product that aligns with your specific application needs and budget constraints.

When considering metal grating, the dimensions and load requirements are essential elements that influence cost. Larger panels or those designed to bear heavier loads naturally require more material and stronger manufacturing processes, thereby increasing the price. It's crucial to work with a vendor who can provide detailed specifications to ensure the grating meets your functional requirements without overspending on unnecessary features. Geographic location and market demand also play significant roles in pricing. Grating prices can fluctuate based on regional manufacturing costs, shipping expenses, and local demand levels. For instance, areas with a thriving industrial sector may see higher grating prices due to increased demand, or conversely, lower prices if there are numerous suppliers. Keeping abreast of market trends and developing relationships with local suppliers can help mitigate these costs. Lastly, supplier trustworthiness can impact both the price and quality of the metal grating you purchase. It is imperative to work with suppliers who have established a reputation for reliability and quality in the industry. Look for suppliers who offer certifications for their products and have a track record of compliance with industry standards. An authoritative supplier not only provides high-quality products but also transparent pricing and meticulous customer service, ensuring you get value for your investment. In conclusion, understanding the various elements that impact metal grating prices allows you to make more informed decisions, ensuring safety, functionality, and cost-effectiveness. Whether considering the material type, manufacturing process, or supplier credibility, each aspect is integral to your purchasing experience. With this comprehensive understanding, you can confidently navigate the landscape of metal grating procurement, assured that you are investing in a product that aligns with your specific application needs and budget constraints.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025