- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 10, 2025 12:29

Back to list

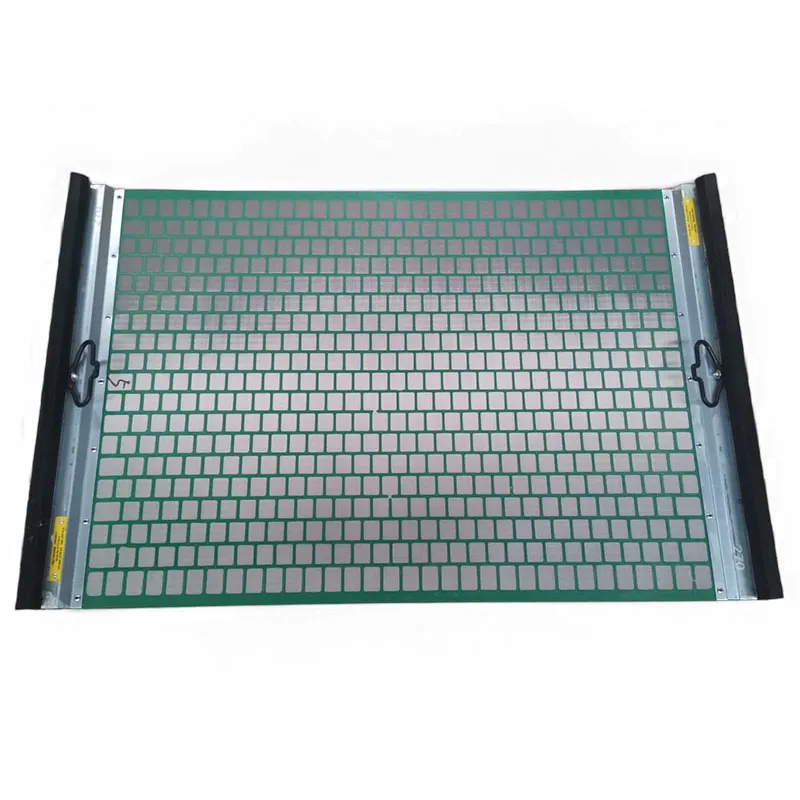

Steel Frame Shale Shaker Screen

Industrial shaker screens play a pivotal role in the separation and classification processes across various industries, from mining to pharmaceuticals. Understanding the intricacies of these screens is essential for ensuring optimal performance and efficiency in screening applications.

From an authoritativeness perspective, industry standards and guidelines are invaluable resources. Organizations such as the American Society for Testing and Materials (ASTM) provide standardized specifications that help manufacturers produce reliable shaker screens. Compliance with such standards is often a mark of quality and reliability, signaling to potential customers that the products will perform as expected under the specified conditions. These standards also facilitate easier integration into existing systems, saving time and reducing the risk of errors during installation. Trustworthiness in the context of industrial shaker screens can be enhanced through comprehensive testing and quality assurance processes. Before deployment, leading manufacturers subject their screens to rigorous testing under simulated operational conditions. This includes assessing the screen’s ability to retain its structural integrity under stress and its resistance to wear and tear over extended periods. Feedback from these tests is used to refine designs and materials further, ensuring the final product meets the highest standards of reliability. For businesses considering investment in industrial shaker screens, partnering with reputable manufacturers with a track record of delivering high-quality products is crucial. Additionally, ongoing training and support ensure that personnel are equipped to operate and maintain these screens effectively, further enhancing trust in the product and the company behind it. Such partnerships often extend to after-sales services, providing vital maintenance and upgrade paths that keep equipment running efficiently, even as operational demands evolve. In conclusion, the effectiveness of industrial shaker screens hinges on numerous factors, including material selection, mesh size, adherence to industry standards, and the thoroughness of quality assurance processes. Stakeholders must leverage experience and expertise while aligning with authoritative industry guidelines to ensure their separation processes are both efficient and reliable. Trust is built not only through product excellence but also via strong partnerships with manufacturers dedicated to supporting their clients throughout the product's lifecycle.

From an authoritativeness perspective, industry standards and guidelines are invaluable resources. Organizations such as the American Society for Testing and Materials (ASTM) provide standardized specifications that help manufacturers produce reliable shaker screens. Compliance with such standards is often a mark of quality and reliability, signaling to potential customers that the products will perform as expected under the specified conditions. These standards also facilitate easier integration into existing systems, saving time and reducing the risk of errors during installation. Trustworthiness in the context of industrial shaker screens can be enhanced through comprehensive testing and quality assurance processes. Before deployment, leading manufacturers subject their screens to rigorous testing under simulated operational conditions. This includes assessing the screen’s ability to retain its structural integrity under stress and its resistance to wear and tear over extended periods. Feedback from these tests is used to refine designs and materials further, ensuring the final product meets the highest standards of reliability. For businesses considering investment in industrial shaker screens, partnering with reputable manufacturers with a track record of delivering high-quality products is crucial. Additionally, ongoing training and support ensure that personnel are equipped to operate and maintain these screens effectively, further enhancing trust in the product and the company behind it. Such partnerships often extend to after-sales services, providing vital maintenance and upgrade paths that keep equipment running efficiently, even as operational demands evolve. In conclusion, the effectiveness of industrial shaker screens hinges on numerous factors, including material selection, mesh size, adherence to industry standards, and the thoroughness of quality assurance processes. Stakeholders must leverage experience and expertise while aligning with authoritative industry guidelines to ensure their separation processes are both efficient and reliable. Trust is built not only through product excellence but also via strong partnerships with manufacturers dedicated to supporting their clients throughout the product's lifecycle.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025