- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 19, 2025 23:53

Back to list

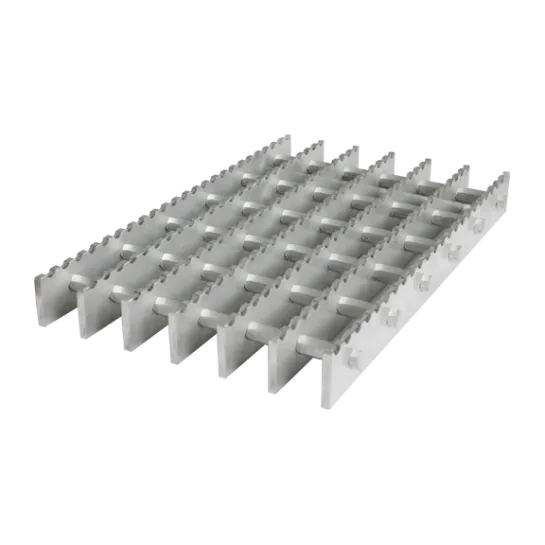

galvanized steel grid

Galvanized steel grids have long been revered in industries ranging from construction to energy due to their unmatched durability and versatile applications. This article delves into the top reasons galvanized steel grids stand out as an optimal choice, discussing authentic experiences, technical expertise, authoritative insights, and factors contributing to their trustworthiness.

Authoritativeness in the industry is reinforced by reputable organizations that endorse the use of galvanized steel grids. Agencies such as the American Institute of Steel Construction (AISC) and the International Association for Bridge and Structural Engineering (IABSE) often point to the technical superiority of galvanized options in their published guidelines. By leveraging insights from these experts, companies can make informed decisions about material selection, confident in the comprehensive backing of the industry. Trustworthiness in the context of galvanized steel grids is often established through demonstrable performance, third-party certifications, and comprehensive testing. For example, corrosion resistance is typically measured using salt spray or humidity tests according to standardized procedures, with results that consistently showcase the material's endurance over time. Manufacturers often offer warranties that further ensure client confidence in long-term performance, providing peace of mind and reducing the perceived risk associated with large infrastructural investments. In conclusion, galvanized steel grids offer an ideal blend of durability, minimal maintenance, and authoritative endorsement that make them a compelling choice for a wide variety of applications. Through expert manufacturing processes, backed by years of empirical evidence and industry recognition, these products exemplify the principles of reliability and excellence. As engineers and decision-makers prioritize materials that align with these attributes, the role of galvanized steel grids solidifies as a trustworthy and expert-backed solution for the challenges of modern construction and beyond.

Authoritativeness in the industry is reinforced by reputable organizations that endorse the use of galvanized steel grids. Agencies such as the American Institute of Steel Construction (AISC) and the International Association for Bridge and Structural Engineering (IABSE) often point to the technical superiority of galvanized options in their published guidelines. By leveraging insights from these experts, companies can make informed decisions about material selection, confident in the comprehensive backing of the industry. Trustworthiness in the context of galvanized steel grids is often established through demonstrable performance, third-party certifications, and comprehensive testing. For example, corrosion resistance is typically measured using salt spray or humidity tests according to standardized procedures, with results that consistently showcase the material's endurance over time. Manufacturers often offer warranties that further ensure client confidence in long-term performance, providing peace of mind and reducing the perceived risk associated with large infrastructural investments. In conclusion, galvanized steel grids offer an ideal blend of durability, minimal maintenance, and authoritative endorsement that make them a compelling choice for a wide variety of applications. Through expert manufacturing processes, backed by years of empirical evidence and industry recognition, these products exemplify the principles of reliability and excellence. As engineers and decision-makers prioritize materials that align with these attributes, the role of galvanized steel grids solidifies as a trustworthy and expert-backed solution for the challenges of modern construction and beyond.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025