- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 02:33

Back to list

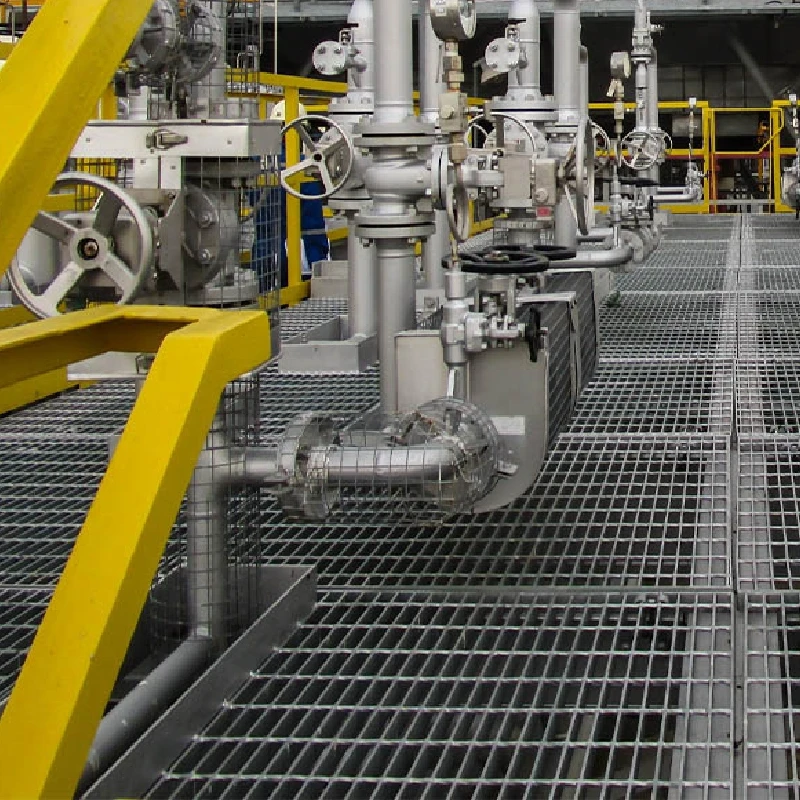

steel walkway grating

Steel grating is an essential component in industrial and commercial settings, offering high strength, durability, and utility. When selecting steel grating for specific applications, understanding the specifications is crucial for ensuring optimal performance and safety. Drawing on years of experience in engineering and product design, this article delves into the various specifications of steel grating, helping stakeholders make informed decisions.

Surface treatment focuses on enhancing the performance and longevity of the steel grating. Common treatments include galvanization, powder coating, and painting. Galvanization is highly popular for its ability to significantly increase corrosion resistance, essential for outdoor installations or environments exposed to harsh chemical conditions. Powder coating offers a similar protective layer with the added benefit of customizable colors, which can help meet visual design standards. Painting, although less durable than galvanization, serves as an economical alternative where environmental conditions are less strenuous. To further ensure safety and effectiveness, take into consideration the attachment methods and finishes. Securing gratings with weld lugs, saddle clips, or threaded studs ensures stability, essential for high-traffic industrial zones. Additionally, options for serrated or plain surfaces address concerns about slip resistance, tailoring safety features to meet regulatory and environmental demands. In terms of credibility and trust, selecting gratings compliant with industry standards, such as those from the American National Standards Institute (ANSI) or the National Association of Architectural Metal Manufacturers (NAAMM), is imperative. Compliance not only affirms product quality but also adheres to safety and performance guidelines universally recognized and respected within the industry. To summarize, specifying the correct steel grating involves a detailed understanding of its material composition, load-bearing prowess, size customization options, and protective treatments. Experts and professionals in engineering, construction, and design rely on these specifications to curate safe, functional, and aesthetically pleasing environments. By emphasizing thorough assessment and industry-standard compliance, stakeholders can ensure that they select the most appropriate steel grating that aligns with both practical needs and safety considerations.

Surface treatment focuses on enhancing the performance and longevity of the steel grating. Common treatments include galvanization, powder coating, and painting. Galvanization is highly popular for its ability to significantly increase corrosion resistance, essential for outdoor installations or environments exposed to harsh chemical conditions. Powder coating offers a similar protective layer with the added benefit of customizable colors, which can help meet visual design standards. Painting, although less durable than galvanization, serves as an economical alternative where environmental conditions are less strenuous. To further ensure safety and effectiveness, take into consideration the attachment methods and finishes. Securing gratings with weld lugs, saddle clips, or threaded studs ensures stability, essential for high-traffic industrial zones. Additionally, options for serrated or plain surfaces address concerns about slip resistance, tailoring safety features to meet regulatory and environmental demands. In terms of credibility and trust, selecting gratings compliant with industry standards, such as those from the American National Standards Institute (ANSI) or the National Association of Architectural Metal Manufacturers (NAAMM), is imperative. Compliance not only affirms product quality but also adheres to safety and performance guidelines universally recognized and respected within the industry. To summarize, specifying the correct steel grating involves a detailed understanding of its material composition, load-bearing prowess, size customization options, and protective treatments. Experts and professionals in engineering, construction, and design rely on these specifications to curate safe, functional, and aesthetically pleasing environments. By emphasizing thorough assessment and industry-standard compliance, stakeholders can ensure that they select the most appropriate steel grating that aligns with both practical needs and safety considerations.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025