- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

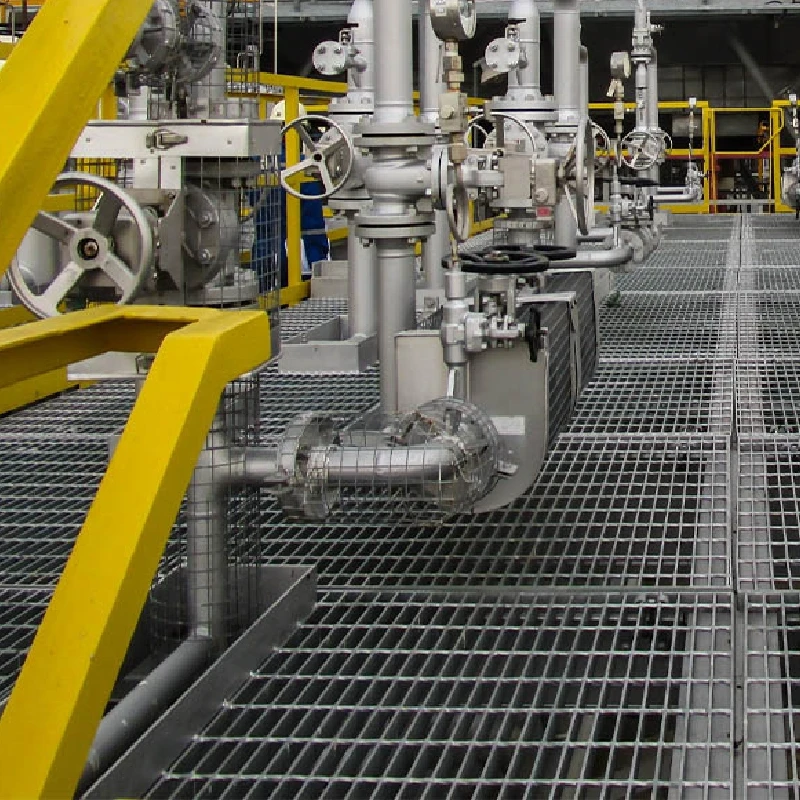

High-Strength Metal Grating Load Tables Accurate Steel Bar Grating Load & Span Charts

Are You Confident in Your Metal Grating's Strength? Here’s What You’re Missing!

Ever worried about whether your metal or steel grating can withstand heavy loads—and found yourself buried in vague data? You’re not alone. In warehouses, industrial sites, and public spaces, structural failures from improper grating selection cause over $1.2 billion in damages every year in the U.S. alone. The peace of mind that comes from choosing the right metal grating load tables

is priceless—let’s show you how easy it can be.

(metal grating load tables)

Technical Advantages: Why Accurate Metal Grating Load Tables Matter

Metal grating load tables are your blueprint to safety. They offer precise data on the safe load capacity, maximum span, and deflection for each grating type. A reliable load table helps you prevent accidents, minimize downtime, and avoid costly repairs. When you select grating based on proper load tables, you know each panel supports the intended weight—no guesswork here.

Let’s take a close look at a typical steel bar grating load table:

Pinpointing your needs with these numbers helps eliminate miscalculations. Whether you’re looking at steel grating span tables or metallic alternatives, this technical foundation matters—no short cuts allowed.

Manufacturer Comparison: What Sets the Best Apart?

Not all manufacturers approach metal grating load tables the same way. Some provide only generic charts, while others, like industry leaders, offer engineered tables tailored to every situation—and tested to meet ANSI/NAAMM MBG 531 standards. Here’s how top suppliers stand out:

- Precision engineering with certified load and span tables

- Comprehensive testing for real-world applications

- Clear, easy-to-read documentation

- Responsive tech support and field assistance

- Robust after-sales warranties

Compare that to low-tier producers who cut corners. Would you risk your team’s safety—or your project budget—on vague info? Of course not. That’s why seasoned buyers always check the specifics behind those steel bar grating load tables. The right data makes all the difference.

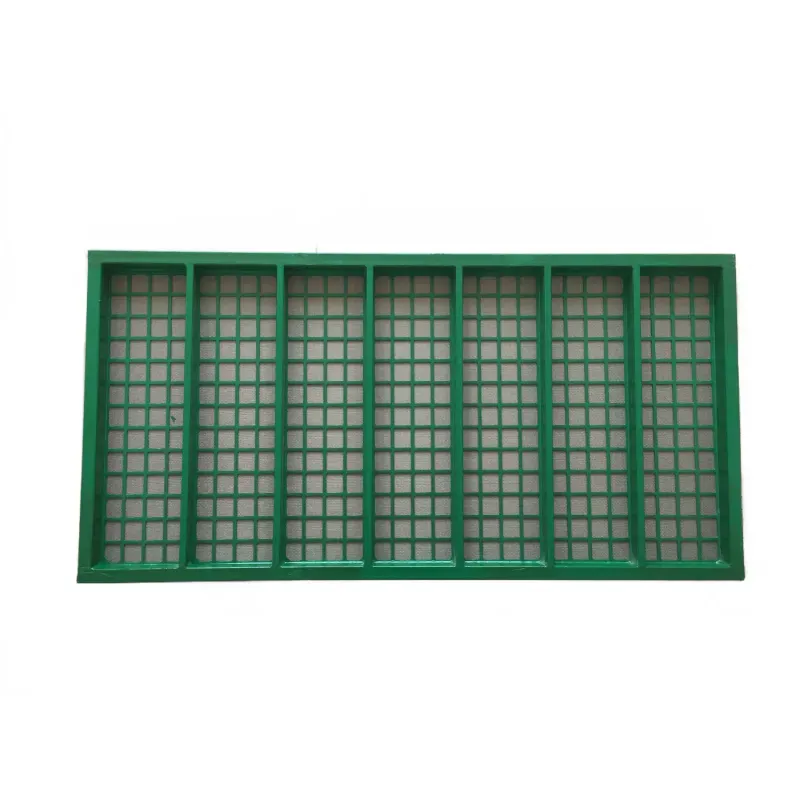

Customized Solutions: Tailoring Metal Grating Load Tables to Your Project

No two installations are alike. From highway overpasses to factory catwalks, your structural demands are unique. Want to optimize cost and safety? That’s where customized load tables step in. Reputable manufacturers analyze:

- Span distances between supports

- Load expectations: uniform, concentrated, or rolling

- Deflection limits for comfort and compliance

- Grating material and finish (galvanized, carbon steel, stainless, aluminum)

Let’s say you’re building a platform with heavy forklift traffic—standard charts won’t cut it. You’ll need project-specific steel grating span tables. Experts supply engineered recommendations, minimizing waste and maximizing lifespan. That’s the real ROI you can show your boss—or your clients.

Eager for a recommendation? Fire over your specs and receive a tailored solution in less than 24 hours. That’s service you can count on.

Application Case: How Load Tables Safeguarded a Mega Distribution Center

Consider this real-world win: A 400,000 square foot logistics center faced issues with overloaded mezzanine walkways. Previous grating, chosen using outdated data, warped within three years, forcing a $500,000 early replacement.

After partnering with a certified manufacturer offering precise metal grating load tables and engineered drawings, the center’s managers:

- Specified the correct bar size and spacing for pedestrian and vehicle loads

- Reduced installation costs by 15% with optimal panel sizing

- Created a safer, more productive environment

- Secured a 10-year warranty

It’s not just about tables. It’s about uptime—and peace of mind. With accurate steel bar grating load tables in hand, their grating has stood the test of time.

Conclusion: The Smart Way to Select Metal Grating – Your Path to Zero Guesswork

Choosing the right grating isn’t something you want to leave to chance—or to outdated information. Authentic, up-to-date metal grating load tables are your one-way ticket to cost savings, regulatory compliance, and above all, safety. Don’t settle for “almost right.” Go with solutions engineered for your needs—and backed by real data.

Upgrade with America’s Leading Provider – [Your Company Name]

At [Your Company Name], we’ve helped thousands of contractors and plant managers eliminate guesswork and boost efficiency. Our professional support team offers:

- Certified metal grating load tables

- Custom engineering for your application

- Competitive pricing—fast delivery

- Unmatched product warranties

Ready to see your project excel? Contact us today for your free consultation and get access to our full set of steel grating span tables. Build it stronger. Build it right—the first time.

Frequently Asked Questions: Metal Grating Load Tables

Q1: What is a metal grating load table?

A metal grating load table is a chart that displays the load-carrying capacity and allowable span of various grating types. It helps engineers and builders select the right material for different applications safely.

Q2: How are steel bar grating load tables calculated?

Manufacturers test sample grating panels using industry standards like ANSI/NAAMM MBG 531. They measure maximum uniform loads, deflection, and span to ensure accurate data.

Q3: What is the difference between a load table and a span table?

A load table shows the maximum load supported at various spans. A span table focuses on the maximum allowable span for specific loads and grating sizes. Both are crucial for planning.

Q4: Why should I use certified steel grating span tables?

Certified tables guarantee your project meets safety codes and load requirements. They are backed by real testing, eliminating the risk of underestimating load capacity.

Q5: Can load tables be customized for special projects?

Yes! Leading manufacturers can create project-specific load and span tables based on your unique load conditions, span lengths, and application needs.

Q6: What happens if I select grating without a proper load table?

You risk structural failure, expensive repairs, or safety violations. Always insist on documented metal grating load tables from trusted suppliers.

Q7: Where can I get professional advice about steel bar grating load tables?

Contact [Your Company Name] today! Our engineers will help you interpret load tables, select products, and supply customized solutions—all backed by expert support.

(metal grating load tables)

FAQS on metal grating load tables

Q: What are metal grating load tables?

A: Metal grating load tables provide information on the load-carrying capacity of different grating types. They help determine which grating can support various weights. These tables are essential for safe and effective grating selection.Q: How do I use steel bar grating load tables?

A: Find your intended span and the load type in the table. Then, select a grating size that meets or exceeds the required load capacity. Always check both uniform and concentrated loads.Q: What are steel grating span tables?

A: Steel grating span tables show maximum span lengths for specific load conditions. They help you choose the right grating size for your structural needs. These tables ensure both safety and efficiency in design.Q: Where can I find accurate metal grating load tables?

A: Accurate metal grating load tables are typically available from manufacturers and industry standards books. Visit reputable supplier websites or request technical data sheets. Always use certified data for your project.Q: Why are load tables important when selecting steel bar grating?

A: Load tables ensure your grating will support necessary loads without failure. They assist in picking the proper bar size and spacing. Using the right table helps prevent costly structural issues.-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025