- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 08:49

Back to list

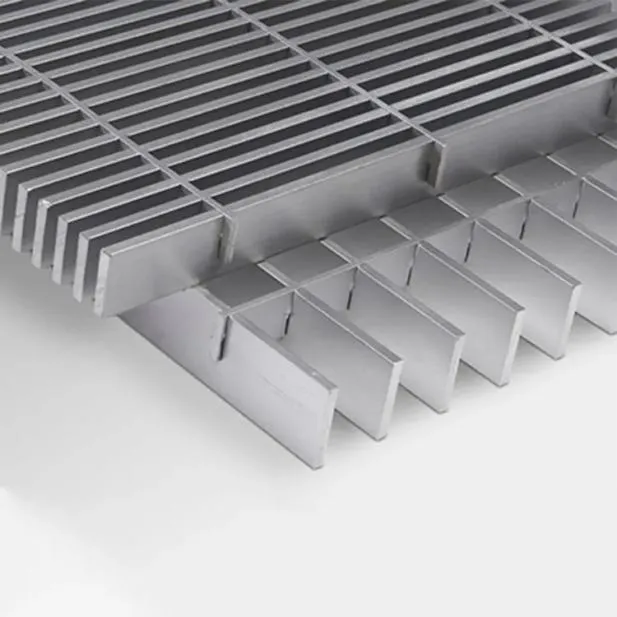

light duty grating

Understanding Light Duty Grating A Comprehensive Guide for Industry Professionals

Selecting the right type of light duty grating involves considering several aspects to ensure optimal performance and safety. Load-bearing capacity is a crucial factor, determining the grating's ability to support the weight of pedestrian or vehicular traffic. The span between supports must be appropriate to prevent deflection and maintain structural integrity. Surface conditions, such as slip resistance, are imperative in applications where safety is a priority, especially in wet or oily environments. Open area percentage is another consideration, affecting factors like ventilation, drainage, and light passage. Over the years, industry standards, such as those established by the National Association of Architectural Metal Manufacturers (NAAMM), have played a pivotal role in guiding the manufacturing and selection of grating. These standards ensure that products meet specific safety, quality, and performance benchmarks, establishing credibility and trust in light duty grating solutions. However, it’s equally essential for professionals to evaluate suppliers’ adherence to these standards, preferring those with a track record of compliance and excellence. Real-world experience with light duty grating underscores its value in enhancing workplace safety and functionality. Feedback from industry professionals highlights specific scenarios where light duty grating significantly contributed to project success. For instance, a manufacturing plant benefitted from the lightweight and durable nature of aluminum grating, facilitating quick installation and providing long-term reliability without compromising safety. Similarly, urban infrastructure projects reported reduced maintenance costs and increased longevity by utilizing stainless steel grating in drainage systems exposed to corrosive elements. In conclusion, light duty grating emerges as a sophisticated solution for myriad industrial applications, offering a balance between functionality, cost-efficiency, and safety. Its selection process demands careful consideration of material properties, application requirements, and compliance with industry standards. As industries advance towards more sustainable and efficient practices, light duty grating remains a fundamental element ensuring infrastructure safety and performance. Industry experts continue to advocate for informed decision-making and adherence to best practices in grating selection, reinforcing the standing of light duty grating as an indispensable asset in modern industrial design.

Selecting the right type of light duty grating involves considering several aspects to ensure optimal performance and safety. Load-bearing capacity is a crucial factor, determining the grating's ability to support the weight of pedestrian or vehicular traffic. The span between supports must be appropriate to prevent deflection and maintain structural integrity. Surface conditions, such as slip resistance, are imperative in applications where safety is a priority, especially in wet or oily environments. Open area percentage is another consideration, affecting factors like ventilation, drainage, and light passage. Over the years, industry standards, such as those established by the National Association of Architectural Metal Manufacturers (NAAMM), have played a pivotal role in guiding the manufacturing and selection of grating. These standards ensure that products meet specific safety, quality, and performance benchmarks, establishing credibility and trust in light duty grating solutions. However, it’s equally essential for professionals to evaluate suppliers’ adherence to these standards, preferring those with a track record of compliance and excellence. Real-world experience with light duty grating underscores its value in enhancing workplace safety and functionality. Feedback from industry professionals highlights specific scenarios where light duty grating significantly contributed to project success. For instance, a manufacturing plant benefitted from the lightweight and durable nature of aluminum grating, facilitating quick installation and providing long-term reliability without compromising safety. Similarly, urban infrastructure projects reported reduced maintenance costs and increased longevity by utilizing stainless steel grating in drainage systems exposed to corrosive elements. In conclusion, light duty grating emerges as a sophisticated solution for myriad industrial applications, offering a balance between functionality, cost-efficiency, and safety. Its selection process demands careful consideration of material properties, application requirements, and compliance with industry standards. As industries advance towards more sustainable and efficient practices, light duty grating remains a fundamental element ensuring infrastructure safety and performance. Industry experts continue to advocate for informed decision-making and adherence to best practices in grating selection, reinforcing the standing of light duty grating as an indispensable asset in modern industrial design.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025