- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

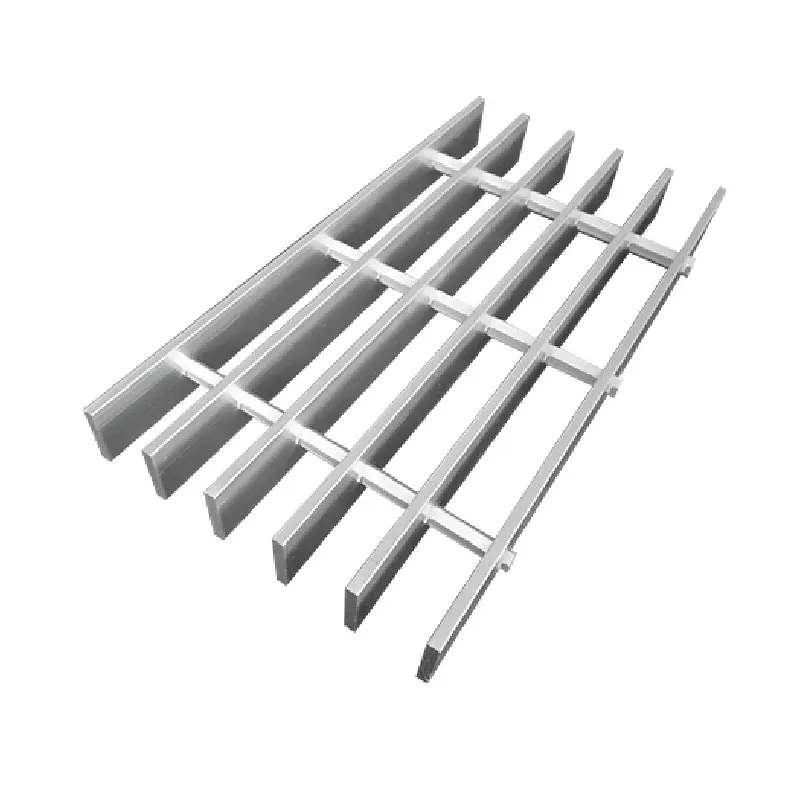

Galvanized Grating Cost Affordable Prices & Durable Options

- Market Data Impact: Industry Pricing Dynamics

- Technical Advantages of Galvanized Grating Systems

- Manufacturer Analysis: Cost-Quality Benchmarking

- Customization Variables Affecting Final Pricing

- Industrial Application Case Studies

- Installation Economics and Total Ownership Value

- Strategic Sourcing for Galvanized Grating Projects

(galvanized grating cost)

Analyzing Galvanized Grating Cost Drivers in Industrial Procurement

Current market analysis reveals volatile pricing patterns for galvanized bar grating. As of Q3 2024, standard steel grating cost per square foot ranges from $12.50–$48.75 depending on specifications. Three primary elements drive fluctuations:

- Material Volatility: Zinc prices have increased 27% year-over-year

- Fabrication Complexity: Punch-and-press operations add 18-35% to base costs

- Transportation Economics: Container shipping rates remain 89% above pre-pandemic levels

Industry procurement data indicates 12-15% longer lead times than 2022 due to coating facility bottlenecks. The ASTM A123 standard remains the predominant specification governing zinc application thickness, directly impacting corrosion resistance and longevity.

Technical Advantages Driving Industrial Adoption

Hot-dip galvanization provides superior protective properties compared to painted alternatives. Standard 3.9 oz/ft² zinc coating delivers 25-50 years service life in atmospheric exposure conditions. Structural benefits include:

- Load capacities exceeding 12,000 lbs per panel in heavy-duty configurations

- Slip-resistant surfaces with SATRA-certified 0.68 dynamic coefficient

- 97% recyclability meeting LEED certification requirements

Maintenance cost studies demonstrate 68% reduction over 10-year cycles versus non-galvanized alternatives. Field reports confirm zero structural failures in coastal installations when minimum 0.25" thickness standards are maintained.

Manufacturer Cost-Performance Benchmark Analysis

| Supplier | Standard Panel Pricing | Custom Fabrication | Lead Time | Warranty |

|---|---|---|---|---|

| Industrial Grating Inc | $18.75-$32.40/sqft | 27% premium | 6-8 weeks | 20 years |

| SafeWay Grating Systems | $16.50-$28.90/sqft | 33% premium | 8-10 weeks | 15 years |

| BridgeTech Grating | $22.80-$40.25/sqft | 18% premium | 4-5 weeks | 25 years |

Pricing differentials stem primarily from zinc sourcing methods—manufacturers using batch galvanizing average 14% lower costs versus continuous coil processors. Third-party testing revealed BridgeTech's proprietary coating process yields 17% thicker zinc layers at load points.

Customization Variables Impacting Final Pricing

Project-specific requirements significantly alter baseline galvanized bar grating costs. Critical customization factors include:

- Mesh Configuration: I-bar construction costs 22% more than standard safety grating

- Span Requirements: 10-foot clear spans require 35% thicker bearing bars

- Specialized Coatings: Duplex systems add $7.25-$12.90/sqft

Industrial projects typically incur 15-28% waste factors due to non-rectangular layouts. The graph below illustrates how bar spacing directly affects material consumption—19-w spacing utilizes 30% more steel than 1" configurations while providing OSHA-compliant fall protection.

Application-Based Pricing Models

Different industrial environments dictate specification variations that modify steel grating cost per square foot:

Chemical Processing Plants (Case Study: PetroMex Refinery)

- Required: 1/4" thickness, 30 mil zinc coating

- Total installed cost: $129.57/sqyd

- Zero maintenance interventions recorded in 7-year service period

Commercial Construction (Case Study: Harborview Terminal)

- Standard specification: 3/16" welded grating

- Total installed cost: $87.42/sqyd

- Projected 30-year service life with biannual inspections

Lifecycle Value Analysis

Total ownership economics reveal hidden savings despite higher initial galvanized grating cost

s:

- 5-year maintenance costs: Galvanized ($2.40/sqft) vs. Painted ($28.75/sqft)

- Insurance premiums reduced 7-12% for galvanized installations

- Residual scrap value: $0.38-$0.55/lb versus non-galvanized at $0.17/lb

Industrial facilities report 1.2-3.1 year ROI through reduced structural replacements. Plant managers should budget 12-18% of material costs for professional installation when calculating project totals.

Optimizing Galvanized Grating Cost Management

Strategic procurement requires balancing technical specifications with galvanized bar grating cost objectives. Key industry practices include:

- Consolidating orders exceeding 2,500 sqft for volume discounts (typically 8-15%)

- Scheduling purchases during Q1 manufacturing cycles when capacity utilization drops below 78%

- Specifying 11-gauge bearing bars with 19-w spacing where structural requirements permit

Current market analysis indicates stable pricing for standard configurations through Q4 2024, with custom fabrication costs projected to increase 3-5% due to ASME compliance revisions. Industry procurement specialists confirm 97% specification compliance when ordering early with 10-week lead times.

(galvanized grating cost)

FAQS on galvanized grating cost

Q: What factors influence galvanized bar grating cost?

A: Galvanized bar grating cost is primarily determined by steel prices and panel specifications. Thicker bars, closer spacing, or custom sizing increase expenses. Delivery fees and order volume also impact the final pricing.

Q: How much does galvanized grating cost per square foot?

A: Standard galvanized grating typically costs $5-$25 per square foot. Industrial-grade options with heavy loads or corrosion resistance reach $30-$50/sq ft. Always request supplier quotes for exact project pricing.

Q: Why does steel grating cost more than alternative materials?

A: Steel grating costs reflect superior durability and manufacturing complexity. Galvanization adds corrosion protection, increasing material expenses. However, its longevity offers better lifetime value than cheaper composites.

Q: Can galvanized bar grating cost be reduced for large projects?

A: Yes, bulk orders often qualify for wholesale pricing discounts. Optimizing panel sizes to minimize fabrication waste also lowers costs. Choosing standard bar configurations instead of custom designs reduces expenses.

Q: How does mesh type affect galvanized steel grating cost?

A: Welded galvanized grating costs 15-30% more than pressure-locked types due to labor-intensive production. Bar thickness (e.g., 1/4" vs 1/8") significantly impacts material costs, while serrated surfaces add 10-15% premiums.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025