- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

feb . 15, 2025 00:45

Back to list

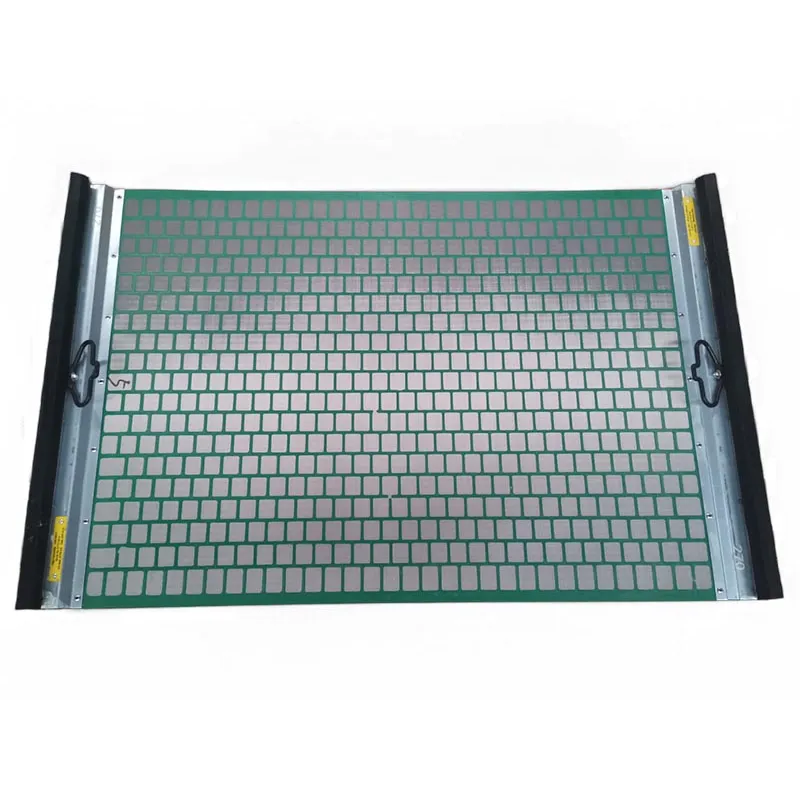

steel grating cost

Steel grating cost is a significant consideration for construction and industrial projects. This article provides an in-depth analysis of the factors influencing steel grating costs, drawing from years of industry experience and expertise.

Labor costs also contribute to the overall expense of steel grating projects. Installation is an intricate process requiring skilled labor, particularly for complex designs or tight deadlines. Choosing a reputable installer with a proven track record can save money in the long run by preventing costly errors and ensuring the grating performs as expected. Shipping and logistics are another critical consideration. Steel grating is heavy, and shipping costs can be substantial, especially if the project is in a remote location. Companies must factor in these expenses when calculating the total cost of steel grating. Working with suppliers who have efficient logistics networks can mitigate these costs and streamline project timelines. The lifecycle cost of steel grating should not be overlooked. Although the initial investment might appear significant, grating made from high-quality materials and installed correctly can offer long-term savings through decreased maintenance needs and enhanced durability. Projects that prioritize upfront quality often benefit from lower total costs over the product's lifespan. In recent years, market dynamics such as fluctuating steel prices and tariff regulations have also impacted steel grating costs. Staying abreast of these trends is crucial for businesses to anticipate price changes and budget accordingly. Engaging with suppliers and industry experts regularly can provide invaluable insights into how market conditions may affect future pricing. In conclusion, the cost of steel grating is influenced by material choice, production methods, customization, labor, shipping, and market dynamics. By understanding these factors and applying industry expertise, businesses can make cost-effective decisions that meet their specific project needs. With the right approach, steel grating can be a financially sound investment, delivering both performance and value over its operational life.

Labor costs also contribute to the overall expense of steel grating projects. Installation is an intricate process requiring skilled labor, particularly for complex designs or tight deadlines. Choosing a reputable installer with a proven track record can save money in the long run by preventing costly errors and ensuring the grating performs as expected. Shipping and logistics are another critical consideration. Steel grating is heavy, and shipping costs can be substantial, especially if the project is in a remote location. Companies must factor in these expenses when calculating the total cost of steel grating. Working with suppliers who have efficient logistics networks can mitigate these costs and streamline project timelines. The lifecycle cost of steel grating should not be overlooked. Although the initial investment might appear significant, grating made from high-quality materials and installed correctly can offer long-term savings through decreased maintenance needs and enhanced durability. Projects that prioritize upfront quality often benefit from lower total costs over the product's lifespan. In recent years, market dynamics such as fluctuating steel prices and tariff regulations have also impacted steel grating costs. Staying abreast of these trends is crucial for businesses to anticipate price changes and budget accordingly. Engaging with suppliers and industry experts regularly can provide invaluable insights into how market conditions may affect future pricing. In conclusion, the cost of steel grating is influenced by material choice, production methods, customization, labor, shipping, and market dynamics. By understanding these factors and applying industry expertise, businesses can make cost-effective decisions that meet their specific project needs. With the right approach, steel grating can be a financially sound investment, delivering both performance and value over its operational life.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025