- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Evaluation of Load Capacity for Metal Gratings in Construction Applications

Understanding Metal Grating Load Tables

Metal grating is an essential component in various industrial and architectural applications, providing safety, support, and ventilation. From walkways and stair treads to platforms and drainage covers, metal grating is a versatile material often made from carbon steel, stainless steel, or aluminum. One crucial aspect of working with metal grating is understanding the load tables associated with it. These tables provide vital information about the loads that different types of grating can safely support.

What are Load Tables?

Load tables for metal grating provide a reference for engineers, architects, and contractors regarding how much weight a specific grating design can handle. They typically include data on the maximum allowable load per square foot, the span (or distance between supports), and the size and material of the grating bars. The tables also consider the type of load—whether it is uniformly distributed or concentrated—enabling users to choose the appropriate grating for their applications.

Factors Affecting Load Capacity

Several factors influence the load capacity of metal grating

1. Material Type The material from which the grating is made significantly impacts its strength. For example, stainless steel grating typically has a higher load capacity than carbon steel grating due to its superior strength and corrosion resistance.

2. Grating Design The design of the grating, including the spacing between bars and the thickness of the bars themselves, affects how much weight the grating can support. Wider spacing between bars may lead to reduced load capacity.

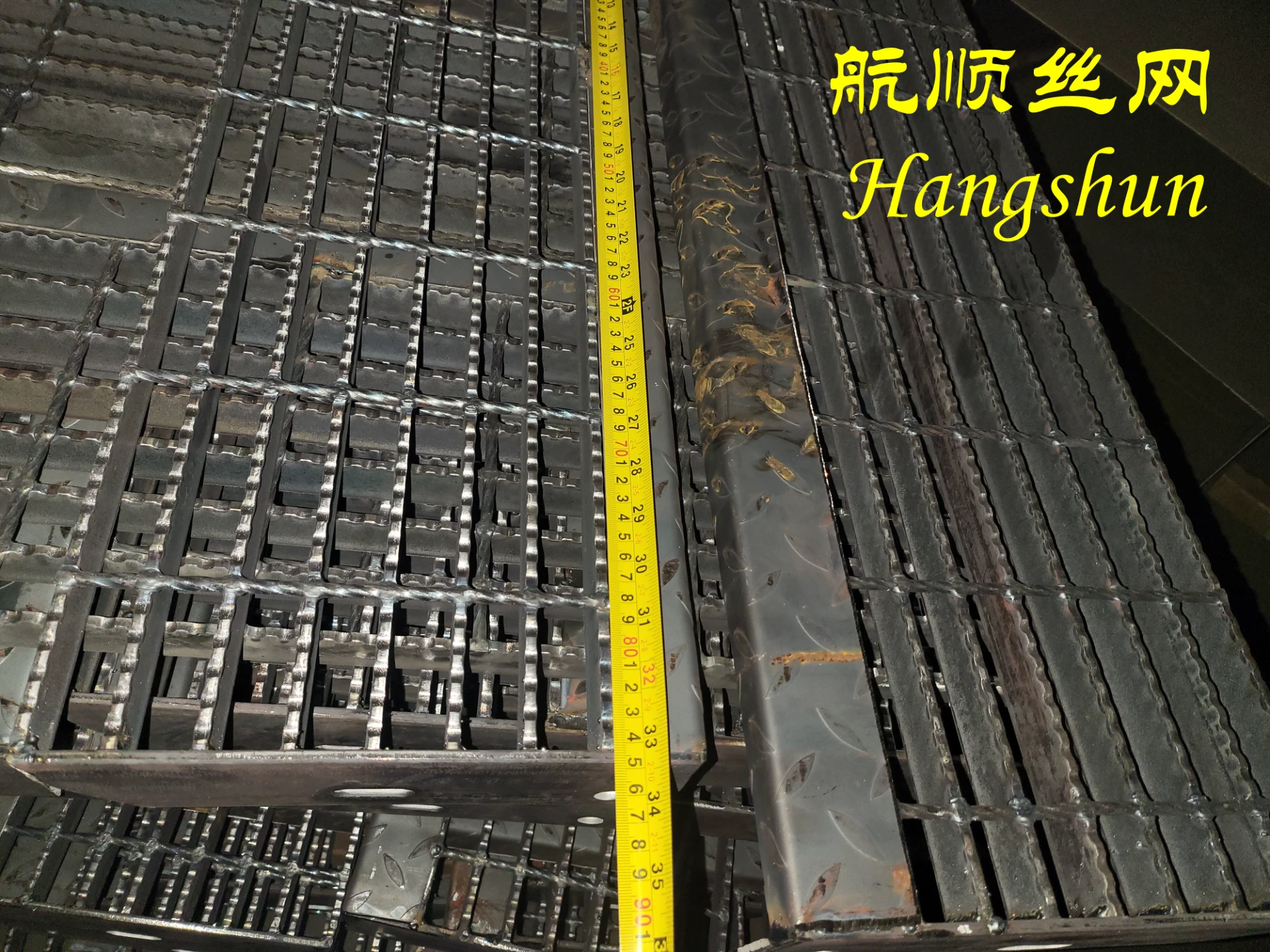

metal grating load tables

3. Span Length The distance between the supports of the grating is another critical factor. As the span increases, the load capacity typically decreases. Load tables will provide guidance on how to optimize span length for various grating designs.

4. Type of Load The tables differentiate between live loads (loads that are temporary and can change, such as people and equipment) and dead loads (permanent loads, such as the weight of the grating itself). Understanding these distinctions is essential for accurate calculations.

5. Environmental Factors Additional factors such as temperature changes, weather conditions, and exposure to chemicals can affect the performance and longevity of metal grating. These should be considered when selecting grating for a specific environment.

Importance of Proper Load Calculation

Using load tables responsibly is crucial in ensuring safety and performance in grating applications. Overloading a grating can lead to catastrophic failures, resulting in injuries or property damage. Therefore, it is imperative for engineers and designers to reference the correct load tables, considering all relevant factors to make informed decisions.

Before commencing any project requiring metal grating, it is advisable to consult with manufacturers or engineering professionals. They can provide insights into the appropriate type of grating, necessary load calculations, and any additional considerations that may apply to specific project conditions.

Conclusion

Metal grating load tables are an indispensable resource in various applications, guiding the selection process based on empirical data and engineering principles. By understanding the variables that influence load capacity and consulting the appropriate tables, designers and engineers can ensure both safety and efficiency in their projects. Proper planning and knowledge of the materials and their limitations will lead to successful and enduring applications of metal grating in our built environment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025