- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 20, 2025 05:10

Back to list

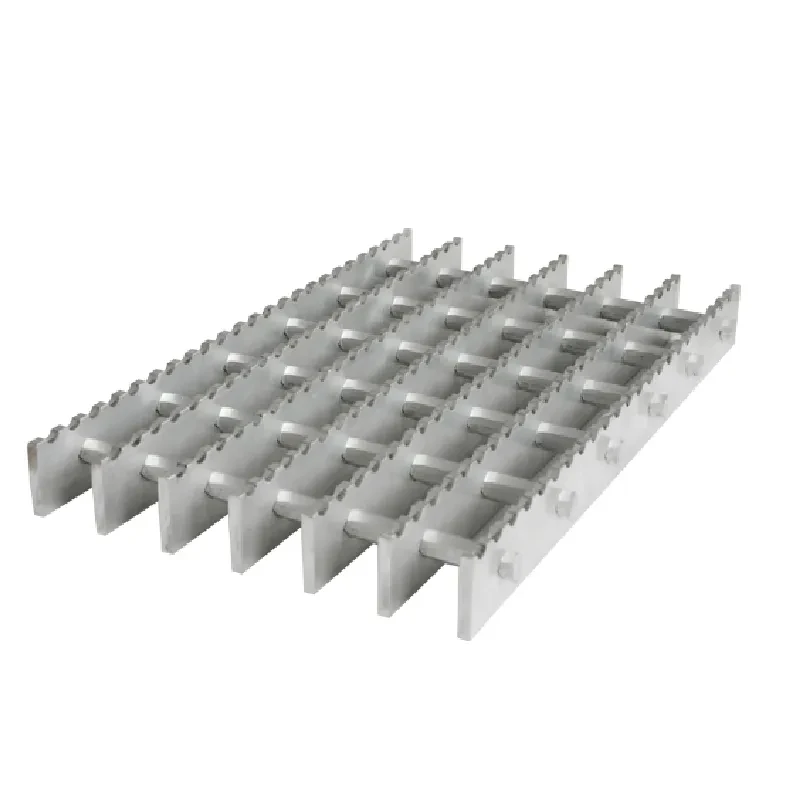

grating stainless

Grating stainless steel is a revolutionary solution transforming industries that prioritize durability, hygiene, and corrosion resistance. As demand continues to rise across various sectors, understanding the unique attributes and applications of stainless steel grating has become essential for industry experts and stakeholders seeking innovative solutions.

The benefits of stainless steel grating extend to environmental considerations as well. As industries strive towards sustainable practices, the recyclability of stainless steel becomes a compelling factor. Unlike other materials, stainless steel can be recycled without loss of quality. This aligns with global sustainability goals, making stainless steel grating a responsible choice for environmentally conscious businesses. Furthermore, choosing the right type of stainless steel grating can optimize performance based on specific operational needs. For instance, considering factors such as mesh size, thickness, and panel size can greatly influence the performance outcome, catering to unique applications for maximum efficiency. Understanding and utilizing stainless steel grating requires a thorough appreciation of the product's engineering excellence and adaptability across various industry applications. It is paramount for decision-makers and engineers to collaborate with trusted manufacturers who adhere to stringent quality standards. This collaboration ensures the grating solutions implemented meet safety and performance requirements, thus bolstering trust and reliability in infrastructure. Ultimately, grating stainless steel is not merely a choice of material but a strategic decision that impacts operational efficiency, safety, and longevity. As industries evolve, the need for innovative, sustainable, and reliable materials continues to grow, with stainless steel grating standing at the forefront of this transformation. By capitalizing on its unique properties, industries can achieve new heights of performance and reliability, meeting the demands of today's rapidly changing world. Industries seeking to incorporate stainless steel grating should prioritize partnering with knowledgeable providers who can offer expertise and tailored solutions. This ensures the material selected not only meets the current demands but is poised to offer enduring performance well into the future.

The benefits of stainless steel grating extend to environmental considerations as well. As industries strive towards sustainable practices, the recyclability of stainless steel becomes a compelling factor. Unlike other materials, stainless steel can be recycled without loss of quality. This aligns with global sustainability goals, making stainless steel grating a responsible choice for environmentally conscious businesses. Furthermore, choosing the right type of stainless steel grating can optimize performance based on specific operational needs. For instance, considering factors such as mesh size, thickness, and panel size can greatly influence the performance outcome, catering to unique applications for maximum efficiency. Understanding and utilizing stainless steel grating requires a thorough appreciation of the product's engineering excellence and adaptability across various industry applications. It is paramount for decision-makers and engineers to collaborate with trusted manufacturers who adhere to stringent quality standards. This collaboration ensures the grating solutions implemented meet safety and performance requirements, thus bolstering trust and reliability in infrastructure. Ultimately, grating stainless steel is not merely a choice of material but a strategic decision that impacts operational efficiency, safety, and longevity. As industries evolve, the need for innovative, sustainable, and reliable materials continues to grow, with stainless steel grating standing at the forefront of this transformation. By capitalizing on its unique properties, industries can achieve new heights of performance and reliability, meeting the demands of today's rapidly changing world. Industries seeking to incorporate stainless steel grating should prioritize partnering with knowledgeable providers who can offer expertise and tailored solutions. This ensures the material selected not only meets the current demands but is poised to offer enduring performance well into the future.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

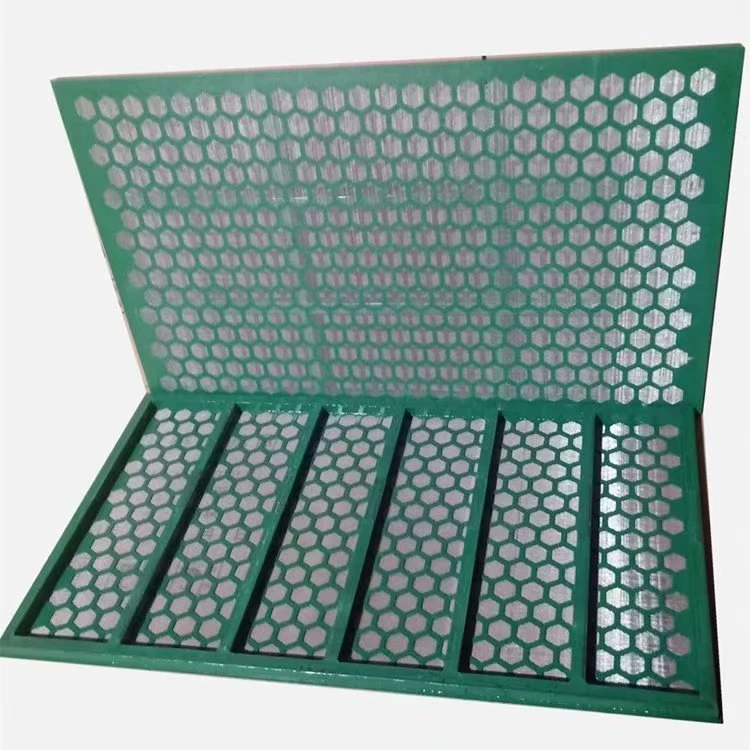

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025