- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

පෙබ. . 16, 2025 12:24

Back to list

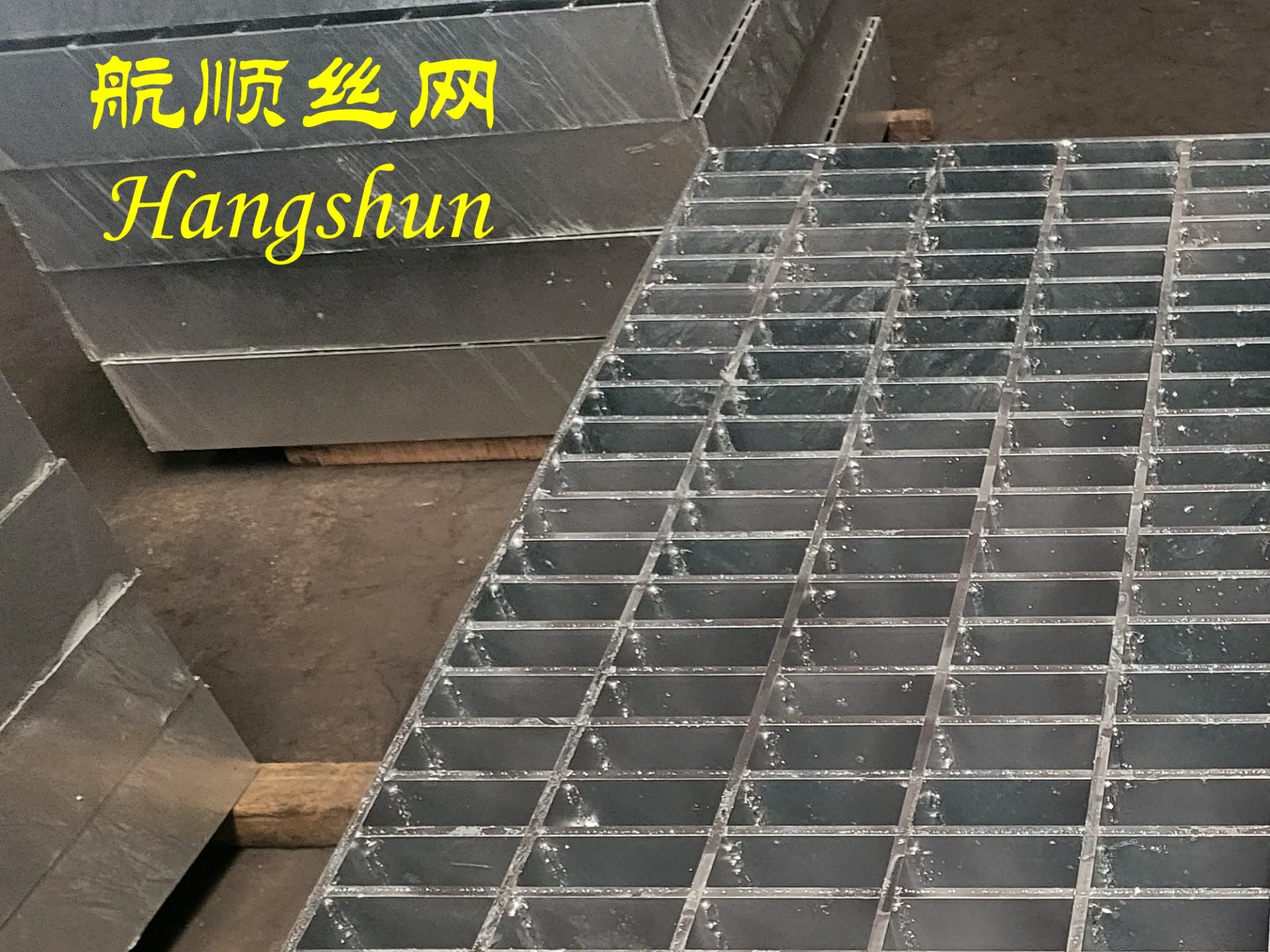

Steel Grating

Industrial floor grates play a crucial role in various sectors, from manufacturing facilities to commercial kitchens and public spaces. These robust grates are pivotal in ensuring safety, hygiene, and functionality within any setting they are employed. Let’s delve into the impeccable craftsmanship and functionality of industrial floor grates, harnessing true expertise and practical experience.

Installing these grates requires a level of precision and understanding that is fostered through experience. It’s a nuanced process, from securing the grate frames within the flooring structure to ensuring alignment and load distribution are optimal. Poor installation can lead to premature wear, noise issues, or even structural failures. Training and experience in handling these tasks ensure that the installation maximizes the grate’s lifespan and performance metrics. Industry veterans know the importance of routinely inspecting and maintaining these installations to ensure longevity and performance reliability. The authoritative stance of companies specializing in industrial flooring solutions comes from decades of refining their products in response to industry shifts and technological advancements. Their roles extend beyond manufacturing to advisory capacities, helping industries navigate regulatory compliance, sustainability impacts, and bespoke design requirements. This commitment enhances their trustworthiness, allowing businesses to rely on their expertise to supply not just a product but a comprehensive solution tailored to their specific operational demand. Trusting in companies with a proven track record is paramount, as this instills confidence that the products delivered will perform flawlessly under expected conditions. Customer testimonials and case studies are illuminating in this regard, providing real-world evidence of product efficacy. Reviews often highlight the seamless integration of floor grates into existing systems, their robustness in high-demand environments, and the tangible benefits observed in organizational safety metrics. Ultimately, industrial floor grates are more than just a flooring component—they are an integral aspect of industrial safety and efficiency. Investing in high-quality grates designed with expert precision and installed by seasoned professionals opens pathways to safer, more efficient, and compliant work environments. For facilities seeking to elevate their operational standards, entrusting the role of floor safety to trustworthy, authoritative providers of industrial floor grates is a strategic decision underscored by long-term benefits in safety, functionality, and compliance.

Installing these grates requires a level of precision and understanding that is fostered through experience. It’s a nuanced process, from securing the grate frames within the flooring structure to ensuring alignment and load distribution are optimal. Poor installation can lead to premature wear, noise issues, or even structural failures. Training and experience in handling these tasks ensure that the installation maximizes the grate’s lifespan and performance metrics. Industry veterans know the importance of routinely inspecting and maintaining these installations to ensure longevity and performance reliability. The authoritative stance of companies specializing in industrial flooring solutions comes from decades of refining their products in response to industry shifts and technological advancements. Their roles extend beyond manufacturing to advisory capacities, helping industries navigate regulatory compliance, sustainability impacts, and bespoke design requirements. This commitment enhances their trustworthiness, allowing businesses to rely on their expertise to supply not just a product but a comprehensive solution tailored to their specific operational demand. Trusting in companies with a proven track record is paramount, as this instills confidence that the products delivered will perform flawlessly under expected conditions. Customer testimonials and case studies are illuminating in this regard, providing real-world evidence of product efficacy. Reviews often highlight the seamless integration of floor grates into existing systems, their robustness in high-demand environments, and the tangible benefits observed in organizational safety metrics. Ultimately, industrial floor grates are more than just a flooring component—they are an integral aspect of industrial safety and efficiency. Investing in high-quality grates designed with expert precision and installed by seasoned professionals opens pathways to safer, more efficient, and compliant work environments. For facilities seeking to elevate their operational standards, entrusting the role of floor safety to trustworthy, authoritative providers of industrial floor grates is a strategic decision underscored by long-term benefits in safety, functionality, and compliance.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025