- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Metal Floor Grating Durable, Slip-Resistant & Heavy-Duty Solutions

- The Essential Guide to Durable and Versatile Floor Metal Grating

- Unmatched Strength and Technical Advantages

- Performance Data That Impresses

- Industry Leaders Comparison

- Custom Solutions for Unique Requirements

- Proven Applications Across Industries

- Selecting Your Ideal Floor Metal Grating

(floor metal grating)

The Essential Guide to Durable and Versatile Floor Metal Grating

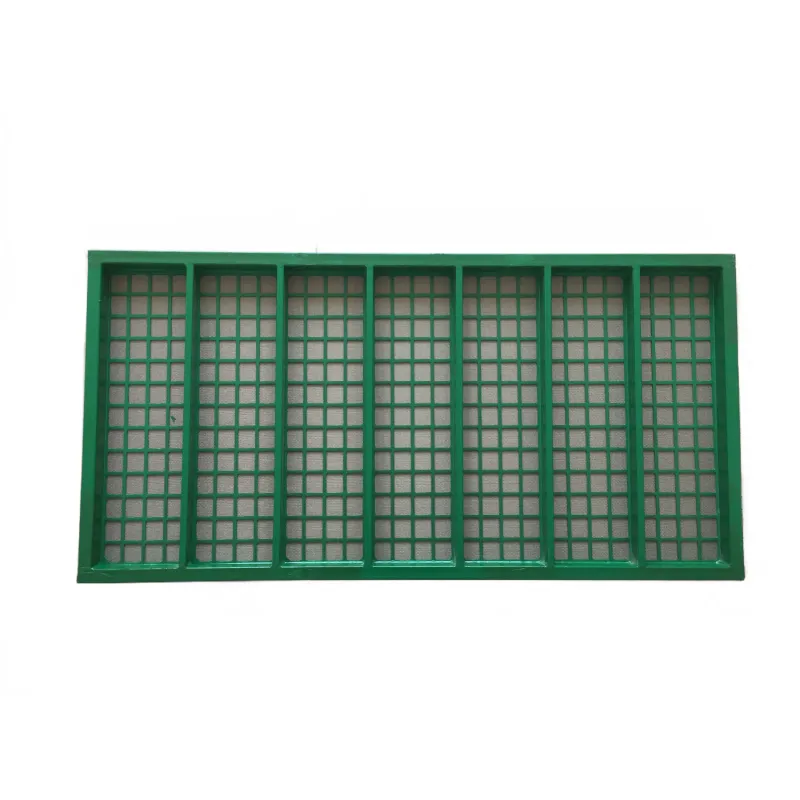

Industrial architects and construction engineers increasingly specify metal floor grating for critical infrastructure projects. This engineered solution combines structural integrity with functional design, delivering safety and longevity in demanding environments. Unlike traditional solid flooring, expanded metal floor grating provides superior drainage, corrosion resistance, and slip prevention - qualities essential in manufacturing plants, offshore platforms, and wastewater treatment facilities.

Contemporary manufacturing techniques have transformed steel grating into a precision component. Galvanization processes now offer 20+ years of corrosion-free performance even in coastal environments. The characteristic open-grid pattern reduces material weight by up to 45% compared to solid alternatives while maintaining impressive load-bearing capacities. Recent innovations include composite polymer coatings that extend service life beyond 30 years in chemical processing plants.

Unmatched Strength and Technical Advantages

Professional-grade expanded metal floor grating demonstrates extraordinary mechanical properties. The interlocking diamond pattern creates a truss-like structure that distributes loads efficiently across multiple bearing points. Industrial testing reveals:

- Average load capacity of 1,000 PSI for standard carbon steel models

- Deflection ratings below L/200 at maximum working loads

- Slip resistance coefficients exceeding OSHA's 0.5 requirement

Environmental adaptability sets modern metal grating apart. Aluminum variants withstand salt spray without coating degradation, while hot-dip galvanized steel options resist corrosion at temperatures up to 390°F. Ventilation properties prevent heat buildup in mechanical rooms, reducing cooling energy consumption by approximately 15% compared to solid decking. Maintenance requirements remain minimal due to self-cleaning designs that prevent debris accumulation.

Performance Data That Impresses

Material science breakthroughs have significantly enhanced grating performance metrics. Stainless steel grating tested in marine environments maintains structural integrity after 25,000+ salt spray exposure hours. Anti-fatigue properties allow carbon steel models to withstand over 10 million load cycles without deformation - critical for busy warehouse mezzanines.

| Material Type | Weight Capacity | Corrosion Resistance | Temperature Range |

|---|---|---|---|

| Galvanized Steel | 1,200 PSI | 25 years urban | -40°F to 750°F |

| Stainless Steel | 1,150 PSI | 40+ years | -100°F to 1500°F |

| Aluminum | 800 PSI | 35+ years coastal | -150°F to 400°F |

Industry Leaders Comparison

Top manufacturers differentiate through proprietary production methods and material formulations. McNICHOLS® utilizes automated laser cutting to achieve dimensional tolerances within 0.01 inches, while Indiana Gratings specializes in press-locking techniques that eliminate weak points at bearing bar connections.

| Manufacturer | Lead Time | Custom Options | Testing Compliance |

|---|---|---|---|

| Nucor Grating | 3-5 days | 15+ surface patterns | NAAMM MBG-531 |

| Ohio Gratings | 7-10 days | 100+ sizing options | ASTM A1011 |

| Marco Specialty | 5-8 days | Hybrid composites | ISO 9001 |

Custom Solutions for Unique Requirements

Modern fabricators accommodate specialized specifications through advanced CNC manufacturing. Industrial facilities frequently require unconventional parameters like:

- Asymmetric bar spacing for chemical drainage optimization

- Compound curvature grating for structural interfaces

- Non-standard alloy blends for extreme temperature applications

Design flexibility includes perforation patterns tailored to specific slip requirements and custom coating thicknesses measured in mils rather than standard micrometers. For pharmaceutical cleanrooms, manufacturers have developed electro-polished stainless steel models that meet FDA 21 CFR Part 11 surface smoothness requirements. Structural engineers can specify localized reinforcement zones beneath heavy machinery to reduce total steel consumption.

Proven Applications Across Industries

Case studies demonstrate how customized floor metal grating

solutions solve persistent industry challenges:

Automotive Manufacturing: Ford's Louisville Assembly Plant installed serrated-surface grating on robotic work cells, reducing liquid pooling by 83% while meeting 6,000 PSI impact resistance requirements. This specialized expanded metal floor grating configuration withstood 15 years of continuous operation before replacement.

Renewable Energy: Offshore wind platforms in the North Sea utilize duplex stainless steel grating that achieves 50-year service projections despite constant salt exposure. The pattern incorporates 60° bearing bars to accommodate dynamic structural loading during 70mph wind events.

Municipal Infrastructure: Chicago's water treatment facilities leveraged aluminum grating in filter beds, cutting installation time by 40% compared to poured concrete while eliminating corrosion concerns associated with chlorine exposure. The design included custom drop-out panels for maintenance access.

Selecting Your Ideal Floor Metal Grating

Project specifications should incorporate both technical requirements and lifecycle considerations when choosing metal floor grating components. Environmental factors like chloride exposure or temperature extremes dictate material selection more than initial cost considerations. Engineering teams should request mill certifications verifying material composition and coating thickness.

Future maintenance accessibility influences grating pattern selection - wider openings facilitate debris clearance in food processing areas while tighter spacing prevents small tool drop-through in maintenance platforms. Consultation with grating specialists during the design phase typically identifies cost-saving opportunities through:

- Load-specific thickness optimization

- Panel size standardization to reduce cutting waste

- Predictive corrosion modeling

The extensive configurability of modern expanded metal floor grating enables engineering solutions unavailable through conventional building materials. Manufacturers continue refining coatings, alloys, and production techniques to extend service life and enhance performance across diverse industrial applications.

(floor metal grating)

FAQS on floor metal grating

Q: What are the benefits of using metal floor grating?

A: Metal floor grating offers durability, high load-bearing capacity, and slip resistance. It is ideal for industrial and outdoor environments requiring ventilation and drainage.

Q: How is expanded metal floor grating different from standard metal grating?

A: Expanded metal floor grating features a woven, diamond-shaped pattern, providing enhanced traction and lightweight strength. It allows airflow and light penetration while maintaining structural integrity.

Q: Where is metal floor grating commonly installed?

A: It is used in factories, platforms, walkways, and drainage areas. Its corrosion-resistant properties make it suitable for harsh or wet conditions.

Q: Can floor metal grating be customized for specific projects?

A: Yes, metal floor grating can be tailored in size, material (steel, aluminum), and finish. Custom options include varying bar spacing and coatings for added protection.

Q: How to maintain expanded metal floor grating?

A: Regular cleaning and periodic inspections for rust or damage are recommended. Coatings like galvanization or paint can extend its lifespan in corrosive environments.

-

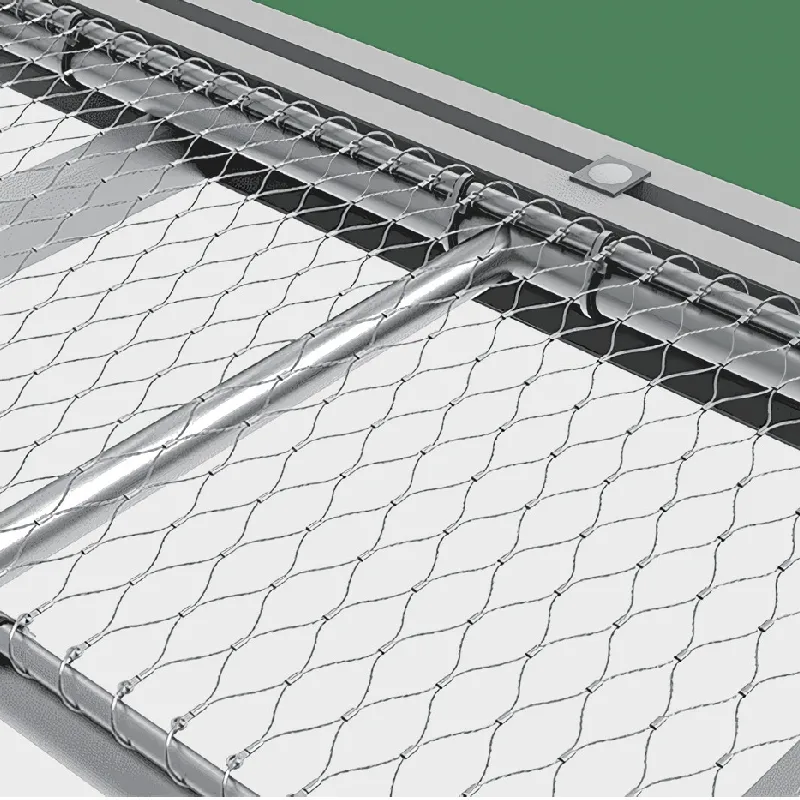

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025