- صنعتي زون، Anping ٽائون جي ڏکڻ، Hengshui، Hebei، چين.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  انگريزي

انگريزي  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- انگريزي

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

The Role of Shale Shaker Screens

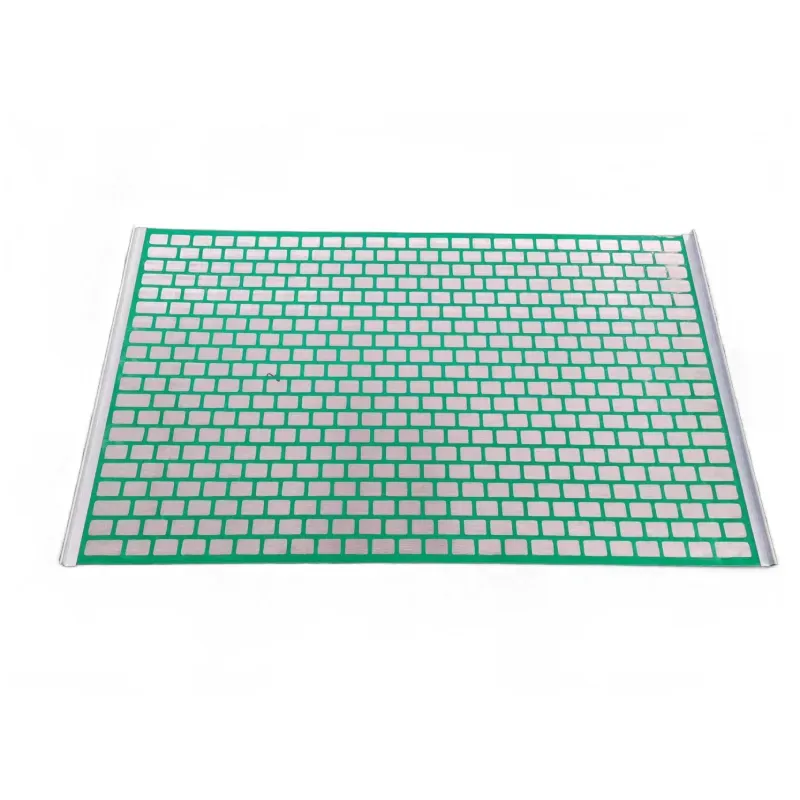

In today’s highly technical and cost-sensitive drilling industry, shale shaker screens play an essential role in the separation of solids from drilling fluids. These screens, placed on top of the shale shakers, are the first line of defense in the solids control system. Without effective shaker screens, valuable drilling fluids would be lost, and equipment efficiency would drastically decrease.

Shale shaker screens are designed to remove large solids such as cuttings from drilling mud as it circulates back to the surface. As the mud passes through vibrating screens, debris is removed while the fluid returns to the active system for reuse. This process reduces waste and saves money on both disposal and fluid replacement. The more effective the screen, the cleaner the drilling fluid remains, which contributes directly to the productivity and safety of the drilling operation.

Modern shale shaker screens come in different mesh sizes and designs to match specific drilling conditions. Whether for oil, gas, geothermal, or water well drilling, the appropriate mesh count and layering system determine the screen’s ability to handle solids while maintaining flow rates. Advanced screen technology has also led to better resistance to wear and tear, allowing screens to last longer under harsh conditions.

Where to Find the Best Shale Shaker Screens for Sale Today

Drilling contractors and mud engineers know the value of finding high-quality shale shaker screens for sale. With so many options on the market, it’s important to choose products that meet both your operational needs and budget constraints. The ideal shale shaker screens for sale should be built to match your shaker’s specifications, whether it's a linear motion, elliptical motion, or balanced elliptical shaker.

When considering shale shaker screens for sale, there are a few important criteria to evaluate: mesh count, screen area, layer configuration (single, double, or triple), screen material, and compatibility with existing equipment. Manufacturers now offer both OEM and replacement screens designed to fit popular brands like Derrick, Swaco, and Brandt. Buying from a reliable source ensures that you receive durable screens with consistent quality.

In addition, leading providers often offer both framed and hook-strip screens, depending on your shaker type. Framed screens tend to be stronger and more durable, while hook-strip screens can be more economical and easier to install. A professional supplier will help assess your fluid loss challenges and recommend the best mesh size and screen type for your operation.

If you’re sourcing shale shaker screens for sale, also look for value-added services like screen customization, fast delivery times, and bulk purchase options. Some suppliers even provide wear-resistant coatings, layered mesh systems, and pre-tensioned panels to extend screen life and efficiency.

Why Choosing the Right Shale Shaker Screen Supplier Matters

Selecting a trustworthy shale shaker screen supplier can significantly affect your drilling performance. A dependable supplier doesn’t just sell screens—they partner with you to understand your operation and provide tailored solutions. Top-tier shale shaker screen suppliers maintain large inventories, support global logistics, and offer technical consulting to help clients minimize downtime and reduce costs.

The hallmark of a good shale shaker screen supplier is consistent quality. Screens should be manufactured with precision and pass stringent quality control checks to ensure uniform mesh, strong bonding, and long-lasting frames. Suppliers that are ISO-certified or who follow international API RP 13C standards are generally more reliable and trusted within the industry.

Besides manufacturing capabilities, the ability to provide immediate shipping and local inventory access is another reason to choose an experienced shale shaker screen supplier. Downtime during drilling can cost thousands of dollars per hour, so having a responsive partner who can deliver quickly is vital. Advanced suppliers also maintain technical teams who can recommend screen specifications for new wells or unique geological formations.

Moreover, a comprehensive product range sets the best shale shaker screen suppliers apart. Whether you need pyramid screens, composite screens, or metal-framed models, a top supplier will have the right solution. Many even provide technical support to optimize screen placement, reduce fluid loss, and increase shaker efficiency.

Innovations in Shaker Screens and Their Impact on Drilling Efficiency

The evolution of shaker screens has dramatically influenced how efficiently modern drilling systems operate. While early screen technologies were limited in mesh variation and screen life, today’s innovations offer advanced filtration, self-cleaning capabilities, and improved fluid retention.

Composite materials now dominate the shaker screens market, replacing traditional metal frames. Composite screens offer a lighter weight, higher resistance to corrosion, and longer operational life. These benefits directly translate to fewer screen changes and lower maintenance costs. Additionally, composite frames can support higher mesh counts, enabling finer separation without compromising flow rate.

Screen mesh design has also seen major improvements. Multilayer bonded meshes allow for better particle separation and increased throughput. Screens with a pyramid structure or corrugated surface area offer a larger effective screening surface, leading to more efficient solid removal. These developments in shaker screens allow operators to maintain cleaner drilling fluid, reduce non-productive time, and extend the life of downstream equipment.

The move toward modular screen design has made it easier to swap out damaged or worn panels. Combined with predictive maintenance systems and sensor technology, operators can now monitor screen wear in real time, maximizing efficiency and reducing unnecessary screen changes.

Ultimately, these innovations in shaker screens help reduce operational costs and environmental impact. Cleaner fluid means less waste and fewer chemicals required to maintain mud quality. That’s why companies continually invest in the latest screen technologies to remain competitive and compliant with environmental standards.

Global Trends Driving Demand for Shale Shaker Screens for Sale

As global energy exploration expands, the demand for reliable shale shaker screens for sale continues to grow. New oil and gas fields, especially in offshore and remote onshore locations, require high-performance solids control systems to meet production and environmental targets. This has placed new expectations on shaker screens to be more efficient, durable, and environmentally friendly.

In regions such as the Middle East, West Africa, and South America, operators are focusing on deepwater and high-pressure formations, where screen failure can lead to severe complications. As a result, the market for premium shale shaker screens for sale is booming. Operators are looking for long-life screens that reduce downtime and meet increasingly strict regulatory requirements.

Sustainability is also influencing buying decisions. With rising scrutiny on drilling waste and water usage, shale shaker screen suppliers are developing greener alternatives that reduce fluid loss and improve cuttings dryness. These developments are not only good for the environment but also offer economic incentives by reducing waste disposal and mud replacement costs.

Finally, digitalization is transforming the way screens are selected and monitored. Smart shakers now use vibration and temperature sensors to evaluate screen performance in real time. This data helps engineers make smarter decisions about screen usage and replacement, further improving efficiency and lowering costs.

shale shaker screens FAQs

What are the most important factors when buying shale shaker screens for sale?

When purchasing shale shaker screens for sale, it’s critical to consider mesh size, screen material, compatibility with your shaker model, and overall durability. Look for screens that meet API RP 13C standards, which ensure performance consistency. Additionally, consider whether the supplier offers custom sizing and quick delivery options, especially if you’re operating in remote locations.

How often should shaker screens be replaced during drilling?

The replacement interval for shaker screens depends on several factors including drilling conditions, mud type, and screen quality. On average, screens should be inspected every shift and replaced when signs of wear or damage appear. High-quality composite screens generally last longer than traditional metal frames, offering extended performance under tough conditions.

What makes a shale shaker screen supplier trustworthy?

A reliable shale shaker screen supplier should offer a wide range of screen types, fast logistics, competitive pricing, and technical support. Certification such as ISO 9001 or adherence to API standards is a sign of professionalism. Reputable suppliers also offer customer support, documentation, and often provide recommendations tailored to specific drilling applications.

Are OEM and replacement shaker screens different in quality?

Not necessarily. Many non-OEM shaker screens are manufactured to equal or better standards than original equipment parts. However, it’s crucial to choose a reputable manufacturer who provides quality control documentation. Quality replacement screens can save money without compromising performance, especially if they match the specifications of your shaker model.

Can shaker screens be reused or cleaned?

In most cases, shaker screens are designed for single-use due to the fine mesh and wear from drilling solids. While some operators attempt cleaning with pressure washers or chemical baths, it often shortens the screen’s life or affects its mesh integrity. For critical operations, it’s best to replace screens regularly to ensure optimal performance.

-

Unlocking Efficiency with Premium Shaker ScreensخبرونAug.05,2025

-

Safety and Style with Metal Grate WalkwayخبرونAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsخبرونAug.05,2025

-

Enhance Your Space with Steel GratingخبرونAug.05,2025

-

Durability with Concrete Weight Coating MeshخبرونAug.05,2025

-

Discover the Power of Perimeter Safety NetخبرونAug.05,2025