- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

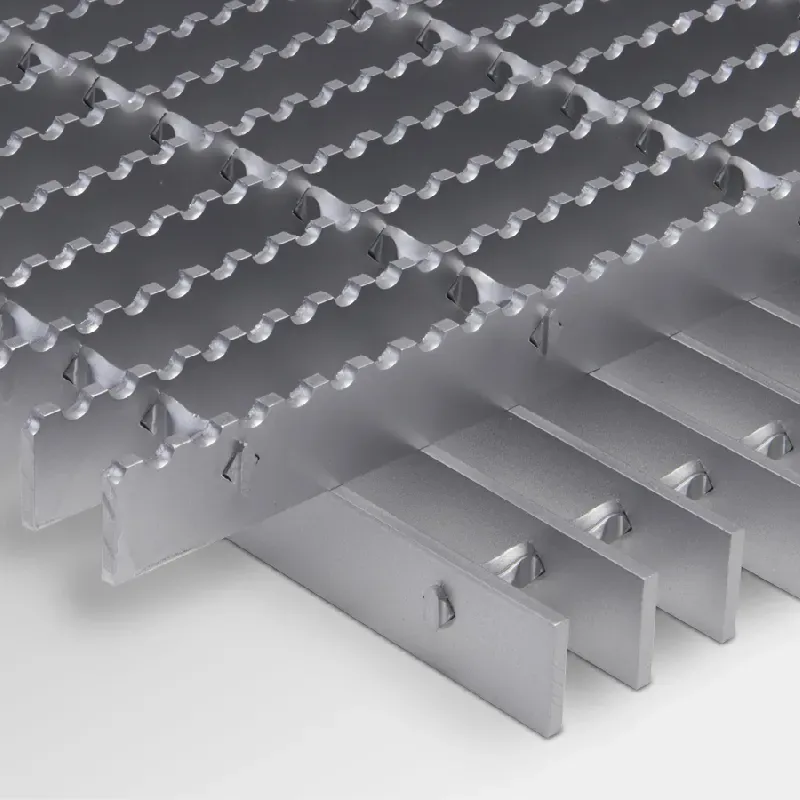

Specifications and Guidelines for Steel Grating Design and Application

Steel Grating Specifications An Overview

Steel grating is a versatile material widely used in various industries for flooring, walkways, drainage covers, and more. Its specifications are crucial since they determine the grating's performance, safety, and overall functional characteristics. In this article, we will explore the essential elements of steel grating specifications, their classifications, and factors to consider when selecting the appropriate type for your application.

What is Steel Grating?

Steel grating is a framework of steel bars that are set at regular intervals, creating a grid-like appearance. The bars can be made from either carbon steel or stainless steel, chosen based on environmental conditions and the load requirements of the specific application. The spaces between the bars allow for light, air, and water to flow through while providing a stable walking surface, making it an ideal choice for industrial flooring and drainage solutions.

Types of Steel Grating

Steel grating can be classified into several types based on the manufacturing process and design

1. Bar Grating This type consists of load-bearing bars and is commonly used for heavy-duty applications. The bars are usually welded or press-locked, providing a strong and stable structure.

2. Expanded Metal Grating Created by slitting and stretching metal sheets, expanded metal provides a lightweight option with a non-slip surface. It is often used for walkways and platforms where visibility is essential.

3. Fiberglass Grating Although not steel, this alternative is worth mentioning due to its growing popularity. Fiberglass grating features a corrosion-resistant surface and is lightweight, making it suited for chemical processing environments.

4. Perforated Grating Featuring punched holes throughout the surface, this type allows for drainage while providing a solid footing. Perforated grating is often used in areas that require both safety and drainage, such as in wastewater treatment facilities.

Key Specifications to Consider

steel grating specifications

When selecting steel grating, several specifications must be taken into account

1. Material The choice between carbon steel and stainless steel is critical. Carbon steel is economical but may require protective coatings to prevent rust. Stainless steel, while more costly, offers superior corrosion resistance and is invaluable in harsh environments.

2. Load Capacity Steel grating is designed to withstand various loads, depending on its application. Load capacity is usually specified in terms of the uniform load a grating can carry based on its size and thickness. Common categories include pedestrian, light vehicular, and heavy-duty loads.

3. Panel Size Grating panels come in different sizes, typically measured in inches or millimeters. Standard dimensions for bar gratings can range from 2 feet to 5 feet in width and up to 20 feet in length.

4. Bar Spacing The distance between the load-bearing bars is another important factor. Common spacing is 1 inch, 1.5 inches, or 2 inches, and it should be chosen based on the intended use and safety requirements.

5. Thickness The thickness of the bars also contributes to the grating's load capacity and durability. Common thicknesses range from 1/4 inch to 1 inch.

6. Surface Finish The finish of the steel grating can impact its performance and appearance. Options include hot-dipped galvanizing, powder coating, and painting. Each finish offers different levels of protection against rust and corrosion.

Safety Standards and Regulations

Ensuring compliance with safety standards is paramount when selecting steel grating for industrial applications. Various organizations, such as the American National Standards Institute (ANSI), set guidelines for the design and manufacturing of grating products. Familiarizing yourself with these regulations can help ensure the safety and reliability of your installation.

Conclusion

Steel grating is an essential material in numerous applications, from industrial flooring to safety walkways. Understanding the specifications associated with steel grating—such as material choice, load capacity, sizing, and finishing—can significantly enhance its functionality and longevity. By carefully considering these aspects and adhering to safety standards, you can make informed decisions that optimize both safety and efficiency in your projects. Whether you’re in construction, manufacturing, or another industry, steel grating stands out as a reliable solution for your needs.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025