- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 20, 2025 09:49

Back to list

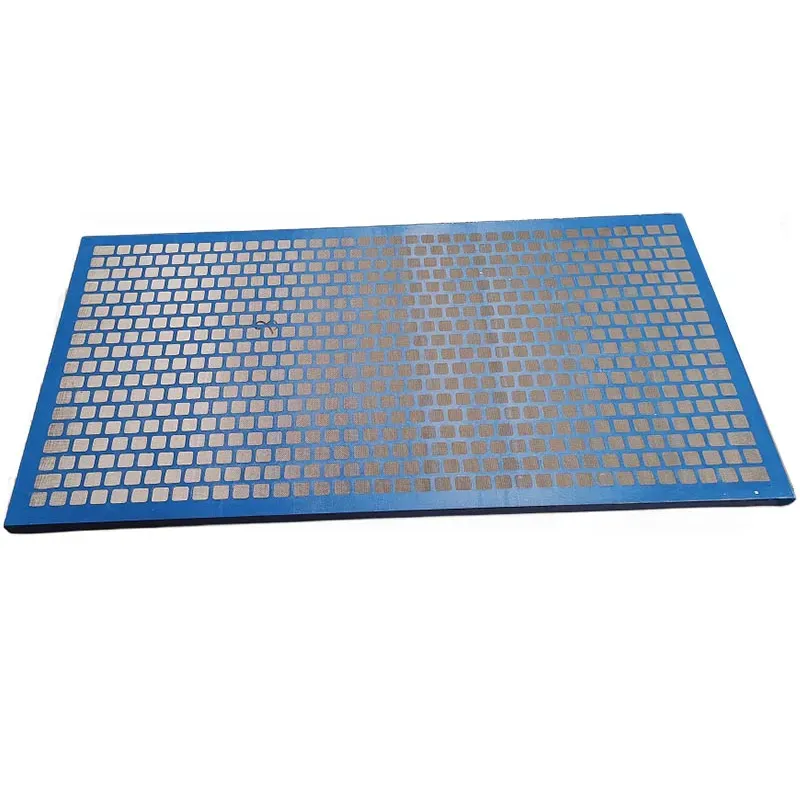

Composite Frame Shaker Screen

In the ever-evolving field of oil and gas exploration, the pivotal role played by shale shaker screens is undeniable. These indispensable components of the solid control system ensure the efficient separation of solids from drilling fluids, thus optimizing operational efficiency and enhancing the productivity of drilling operations. For industry professionals seeking top-of-the-line shale shaker screens for sale, it is essential to delve into a comprehensive understanding of these tools, backed by genuine experience and authoritative insights.

Authoritative knowledge also highlights the innovation infused in modern shale shaker screens, where recent advancements have integrated features to boost vibrational performance and minimize blinding and plugging. Such enhancements are critical for seamless operations, especially in high-stakes drilling projects. Industry leaders now gravitate towards screen designs that reduce downtime and offer swift assembly and disassembly, thereby increasing the agility of field operations. Trustworthiness in the context of shale shaker screens transcends product quality and extends to sourcing practices. Procuring screens from reputed suppliers with a proven track record ensures not only product excellence but also conformity with industry standards and regulations. Reviews and testimonials from industry peers provide invaluable insights into the performance and reliability of screens, aiding in making informed purchasing decisions. The usage of shale shaker screens also embodies a significant environmental responsibility. Effective solid separation reduces the environmental footprint of drilling operations by preventing the disposal of contaminated drilling mud. As an expert, embracing eco-sensitive practices positions professionals as responsible stewards of the environment, a testament to the authoritativeness and trustworthiness of their operations. In conclusion, the pursuit of shale shaker screens for sale is best approached with an intrinsic understanding of technical specifications, quality standards, and compatibility factors. Industry expertise sanctions informed decision-making that aligns with operational requirements and sustainability goals. By anchoring purchases in genuine experience and authoritative research, oil and gas professionals can bolster both the effectiveness and the credibility of their drilling operations, ultimately leading to enhanced economic and environmental outcomes.

Authoritative knowledge also highlights the innovation infused in modern shale shaker screens, where recent advancements have integrated features to boost vibrational performance and minimize blinding and plugging. Such enhancements are critical for seamless operations, especially in high-stakes drilling projects. Industry leaders now gravitate towards screen designs that reduce downtime and offer swift assembly and disassembly, thereby increasing the agility of field operations. Trustworthiness in the context of shale shaker screens transcends product quality and extends to sourcing practices. Procuring screens from reputed suppliers with a proven track record ensures not only product excellence but also conformity with industry standards and regulations. Reviews and testimonials from industry peers provide invaluable insights into the performance and reliability of screens, aiding in making informed purchasing decisions. The usage of shale shaker screens also embodies a significant environmental responsibility. Effective solid separation reduces the environmental footprint of drilling operations by preventing the disposal of contaminated drilling mud. As an expert, embracing eco-sensitive practices positions professionals as responsible stewards of the environment, a testament to the authoritativeness and trustworthiness of their operations. In conclusion, the pursuit of shale shaker screens for sale is best approached with an intrinsic understanding of technical specifications, quality standards, and compatibility factors. Industry expertise sanctions informed decision-making that aligns with operational requirements and sustainability goals. By anchoring purchases in genuine experience and authoritative research, oil and gas professionals can bolster both the effectiveness and the credibility of their drilling operations, ultimately leading to enhanced economic and environmental outcomes.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025