- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shaker screens for sale

Shale Shaker Screens for Sale Essential Equipment for Efficient Drilling Operations

In the ever-evolving world of oil and gas extraction, efficiency and functionality are paramount. Among the critical components in drilling operations, shale shaker screens play an indispensable role. These screens are essential for the separation of drilling fluids from cuttings, ensuring that the drilling process is both efficient and cost-effective. If you are in the market for shale shaker screens, understanding their structure, types, and where to purchase them will help optimize your operations.

Understanding Shale Shaker Screens

Shale shaker screens are designed to fit on top of shale shakers, which are mechanical devices that separate solid particulates from drilling fluids. The screens are typically made from a steel frame and covered with mesh made from either woven wire cloth or synthetic materials. The choice of mesh size and material is crucial, as it determines the screen's effectiveness in filtering unwanted particles without clogging.

When drilling for oil and gas, the requirements of different formations dictate the specifications of the shaker screens. The mesh must be fine enough to separate the desired fluids from the drill cuttings while allowing the lightweight drilling mud to pass through. Therefore, understanding the geological conditions of the drilling site will aid you in selecting the right screens.

Types of Shale Shaker Screens

There are various types of shale shaker screens available, each suited for different drilling conditions

1. Made of Different Materials Shale shaker screens can be made from metal or synthetic materials, with metal options typically offering more durability, whereas synthetic varieties can provide flexibility and reduced weight.

2. Steel Frame vs. Composite Frame Steel frames are robust and provide a long lifespan for heavy-duty applications. In contrast, composite frames are lighter and can help reduce the overall weight of the shaker setup.

3. Various Mesh Sizes The mesh size plays a critical role in determining the effectiveness of solids removal. Coarser mesh screens are suitable for larger solids, while finer mesh options are necessary for dealing with smaller particles.

shale shaker screens for sale

4. Compliance with API Standards The American Petroleum Institute (API) sets standardized specifications for shaker screens. Ensure that the products you purchase comply with these standards for consistent performance.

Where to Find Shale Shaker Screens for Sale

When looking for shale shaker screens for sale, it’s vital to consider a few important factors to ensure you are making the right decision for your drilling operations.

1. Reputable Suppliers Purchase from well-established manufacturers or suppliers with a strong reputation in the oil and gas industry. They often provide various options and can guide you based on your specific needs.

2. Customization Options Many suppliers offer customization based on specific drilling conditions. Custom screens can enhance performance and efficiency, so look for those who provide tailored solutions.

3. Quality Assurance Ensure that the product comes with quality guarantees. Reliable suppliers often perform rigorous testing on their screens to meet industry standards.

4. Price and Availability Costs can vary significantly, so it’s worth comparing prices across different suppliers. Ensure that you consider the total cost, including shipping and potential import fees if ordering from international suppliers.

5. Technical Support Good suppliers will provide technical support for installation and maintenance, ensuring your screens function optimally throughout their lifespan.

Conclusion

Investing in high-quality shale shaker screens is essential for maintaining drilling efficiency and reducing operational costs. By understanding the types of screens available, their specifications, and where to purchase them, drilling companies can enhance their operational capabilities and effectively handle the demands of various drilling conditions. As trends in the oil and gas industry continue to evolve, staying informed about advancements in shale shaker technology will provide a competitive edge in the market.

-

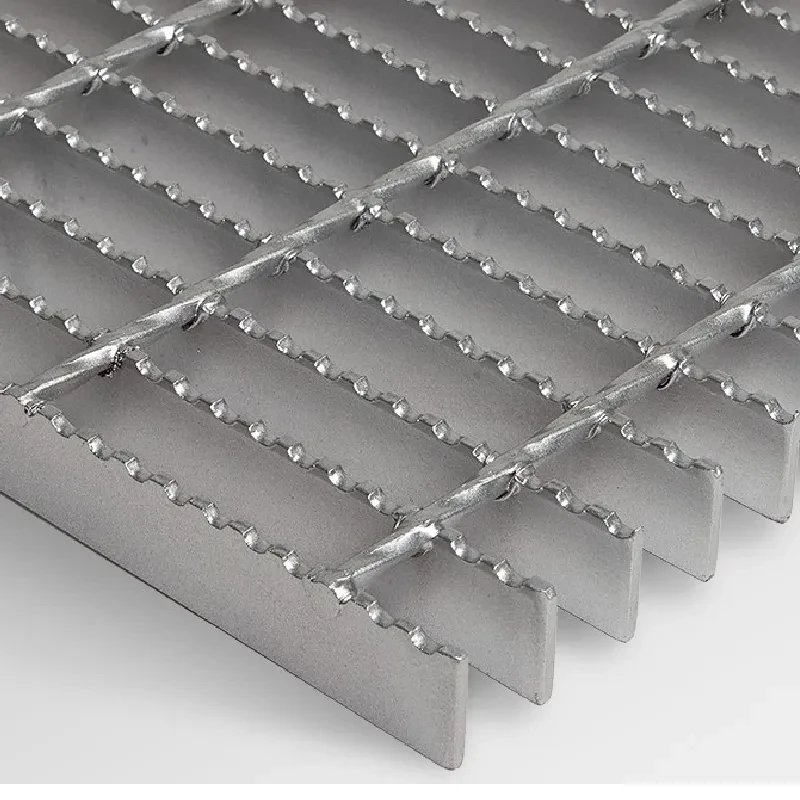

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025