- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

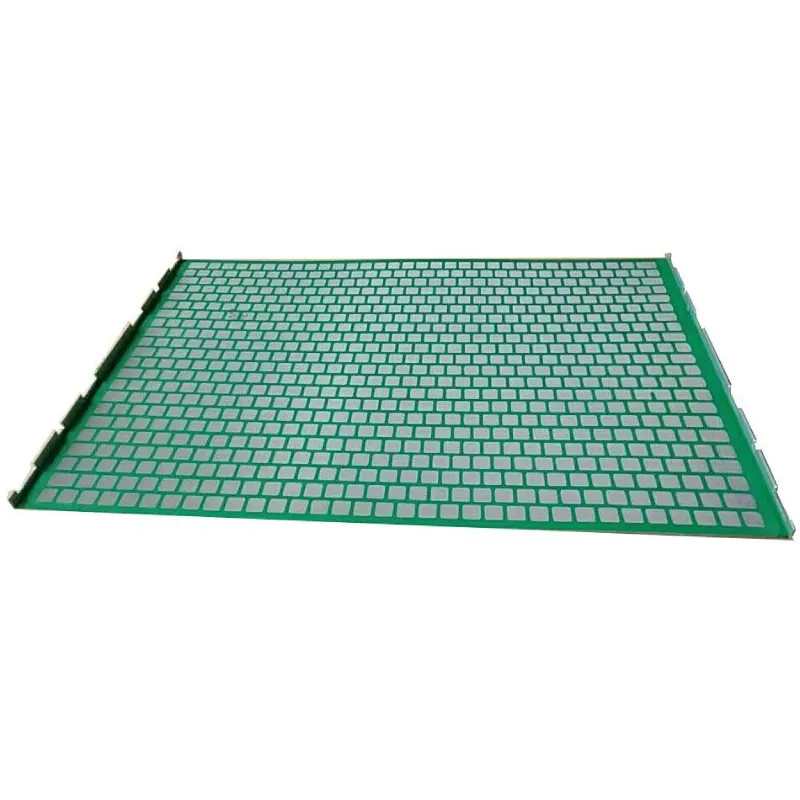

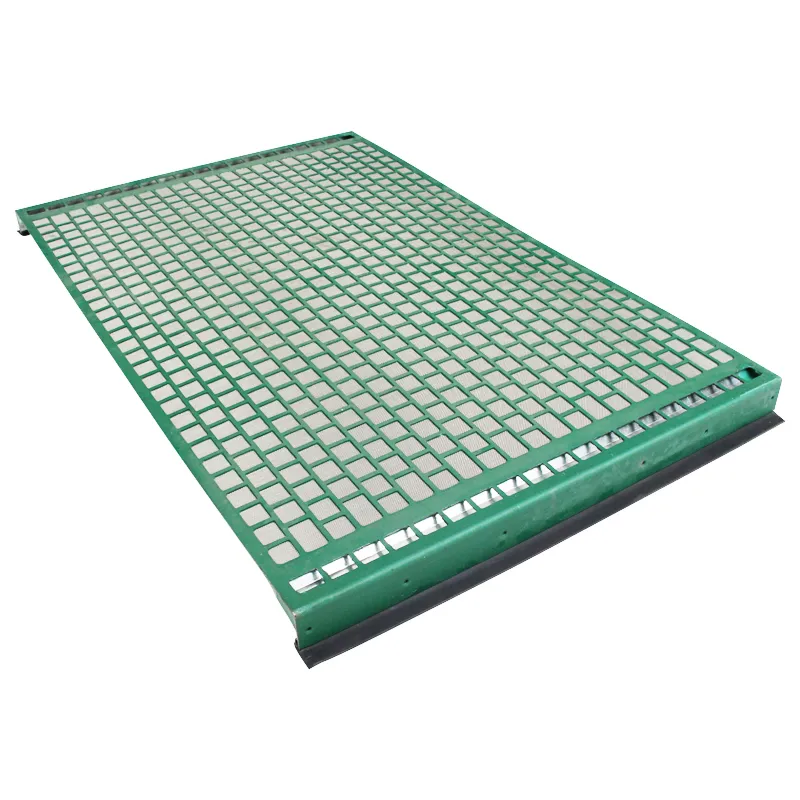

Premium Shale Shaker Screens: Efficient Solids Control Solutions

Understanding the Pivotal Role of Shale Shaker Screen in Advanced Drilling Operations

In the intricate world of oil and gas exploration, efficient solids control is not merely a preference but a fundamental requirement for optimizing drilling performance, ensuring wellbore stability, and managing operational costs. At the heart of this critical process lies the shale shaker screen, a seemingly simple yet technologically advanced component that acts as the primary defense against undesirable solids in drilling fluids. As an essential part of the drilling rig's solids control system, the shale shaker screen is tasked with separating drill cuttings and other drilled solids from the valuable drilling fluid, or "mud," allowing the clean fluid to be recirculated downhole. This process not only preserves the integrity and expensive properties of the drilling fluid but also significantly reduces wear and tear on drilling equipment, mitigates environmental impact by minimizing waste volume, and ultimately contributes to faster, safer, and more cost-effective drilling operations. The evolution of drilling techniques, particularly the widespread adoption of horizontal and unconventional drilling, has amplified the demands placed on these screens, necessitating ever-higher levels of precision, durability, and efficiency. Modern drilling environments, characterized by high temperatures, abrasive cuttings, and complex mud chemistries, require shale shaker screens that can withstand extreme conditions while delivering consistent, high-performance solids removal. The selection of the right screen, therefore, transcends a simple purchasing decision, becoming a strategic choice that directly impacts drilling economics and environmental stewardship. Factors such as screen mesh configuration, frame material, manufacturing precision, and overall design significantly influence a screen's ability to maintain optimal mud properties, extend the life of drilling bits, pumps, and other equipment, and minimize the volume of waste generated at the wellsite. The global market for shale shaker screens is driven by the dynamic shifts in drilling activities, technological advancements in solids control, and stringent environmental regulations. As the industry continues to push the boundaries of energy extraction into more challenging formations and deeper reservoirs, the demand for high-quality, reliable, and durable shale shaker screens remains robust. Our Hook Strip Flat Screen product, designed with cutting-edge materials and precision manufacturing, exemplifies the advancements in this field, offering superior performance and longevity to meet the rigorous demands of contemporary drilling projects worldwide. Its design specifically addresses the need for efficient solids separation under diverse operational conditions, highlighting its capability to enhance drilling fluid reclamation and reduce disposal costs, thereby contributing significantly to the overall profitability and environmental responsibility of drilling campaigns. The core principle guiding the development of such advanced screens is the balance between maximizing fluid recovery and achieving an optimal cut point, ensuring that only unwanted solids are removed, while valuable drilling fluid components are retained and returned to the system for reuse. This equilibrium is crucial for maintaining the rheological properties of the mud, which directly impacts drilling efficiency and wellbore stability, preventing issues such as stuck pipe or formation damage. Thus, investing in a high-quality shale shaker screen is a proactive step towards achieving operational excellence in all drilling applications.

Technical Specifications and Performance of Advanced Shale Shaker Screen Mesh Systems

The performance of a shale shaker screen is intrinsically linked to its technical specifications, particularly the design and material of its shale shaker screen mesh. At the core, these screens are engineered composite structures, typically comprising multiple layers of precisely woven wire mesh bonded to a robust metal or composite frame. The most common mesh material is high-quality stainless steel, often SUS304 or SUS316, selected for its exceptional corrosion resistance and mechanical strength, crucial for enduring the harsh chemical environment of drilling fluids and the abrasive nature of drill cuttings. The weaving pattern and wire diameter of each mesh layer are meticulously controlled to achieve specific separation characteristics. For instance, a coarser mesh layer provides structural support and initial removal of larger solids, while progressively finer layers ensure the capture of smaller particles. The innovation in shale shaker screen mesh technology has led to the development of multi-layered screens, such as the widely adopted pyramid or corrugated designs, which offer significantly increased non-blanked screen area compared to traditional flat screens. This expanded surface area enhances fluid handling capacity and improves separation efficiency without requiring larger shaker units. Key performance parameters, rigorously defined by API RP 13C (Recommended Practice for Drilling Fluid Processing Systems Evaluation), include conductance, cut point (D100), and non-blanked area. Conductance, measured in kD/(Pa·s), quantifies the screen's ability to allow fluid to pass through, directly impacting the shaker's processing capacity. A higher conductance value indicates superior fluid throughput. The cut point, or D100, represents the particle size at which 100% of particles larger than this size are retained by the screen, offering a precise measure of separation effectiveness. Achieving an optimal balance between high conductance and a fine cut point is the hallmark of a high-performance shale shaker screen. The non-blanked area refers to the actual open area of the mesh available for fluid passage, and advanced screen designs strive to maximize this while maintaining structural integrity. Frame materials are equally vital, ranging from traditional steel frames, which offer excellent rigidity and durability, to lighter composite frames, which reduce total screen weight and can extend shaker bearing life. The bonding process between the mesh layers and the frame is also critical; advanced techniques, often involving specialized adhesives and high-pressure molding, ensure a secure, long-lasting bond that prevents delamination and premature screen failure, even under intense vibration and fluid flow. Furthermore, the overall design of the Hook Strip Flat Screen emphasizes ease of installation and replacement, which are significant operational advantages, minimizing downtime on the rig. The hook strip mechanism provides a secure yet flexible attachment to the shaker deck, allowing for quick screen changes and ensuring a tight seal to prevent fluid bypass. The rigorous quality control applied during the manufacturing of the Hook Strip Flat Screen guarantees that each unit meets the stringent API RP 13C standards, ensuring consistent performance, reliability, and extended service life in diverse drilling applications. Understanding these technical nuances allows drilling operators to make informed decisions, selecting screens that not only fit their equipment but also optimize their solids control strategy for maximum efficiency and cost-effectiveness. The continuous innovation in shale shaker screen mesh technology is a testament to the industry's commitment to enhancing drilling efficiency and environmental performance.

The Precision Engineering Behind Shale Shaker Screen Manufacturing

The production of a high-performance shale shaker screen is a sophisticated multi-stage process that combines advanced material science, precision engineering, and rigorous quality control. It begins with the meticulous selection of raw materials, primarily high-grade stainless steel wire, typically SUS304 or SUS316, renowned for its excellent corrosion resistance, high tensile strength, and durability—qualities indispensable for the demanding environment of drilling fluid processing. This wire undergoes a precise weaving process to create various mesh layers, each with a specific aperture size and wire diameter, conforming to the stringent requirements of API RP 13C. Concurrently, the screen frame, which can be made from high-strength steel or a composite polymer, is fabricated. For steel frames, processes such as stamping, welding, or even CNC machining for specific components like the hook strips, ensure dimensional accuracy and robust structural integrity. Composite frames, on the other hand, often utilize injection molding techniques to create lightweight yet incredibly durable structures that are resistant to corrosion and fatigue. Once the mesh layers are woven and the frame is prepared, the core manufacturing step involves bonding these components together. This is a critical stage where multiple mesh layers are precisely tensioned and then securely bonded to the frame using advanced techniques such as vacuum thermal bonding or high-pressure epoxy bonding. This ensures that the mesh remains taut and does not delaminate or sag under the high G-forces and fluid pressures experienced during operation, which is paramount for preventing blinding and maintaining consistent separation efficiency. The tensioning process is particularly vital, as proper tension contributes significantly to the screen's lifespan and its ability to withstand severe vibrations without tearing. After the bonding, each shale shaker screen undergoes a series of stringent quality inspections. These checks encompass visual inspections for defects, dimensional accuracy verification using precision tools, and functional testing to ensure proper fit and tension. Crucially, adherence to international standards such as ISO 9001 (Quality Management Systems) and API RP 13C is not merely a benchmark but a foundational principle throughout the manufacturing process, guaranteeing that the final product consistently meets or exceeds industry performance expectations. For example, testing might involve measuring screen conductance and cut point using specialized equipment to confirm that the screen performs as designed. The typical service life of a shale shaker screen is inherently variable, influenced by factors like the abrasiveness of drilled cuttings, drilling fluid rheology, shaker vibration settings, and maintenance practices. However, screens manufactured with superior materials and precise processes, like the Hook Strip Flat Screen, are designed for extended longevity, often outperforming lower-quality alternatives by a significant margin. These screens find extensive application across various industries beyond traditional oil and gas, including mining, industrial wastewater treatment, metallurgy, and construction, wherever efficient solid-liquid separation is required. Their robust design, coupled with features like anti-corrosion properties and energy-efficient fluid processing, makes them ideal for environments demanding high reliability and sustainability. By minimizing fluid loss and enhancing solids removal, these screens contribute directly to operational efficiencies and reduced environmental footprints, offering tangible benefits that extend beyond the initial purchase price to long-term operational savings and improved regulatory compliance.

Optimizing Drilling Efficiency: Shale Shaker Screen Applications and Benefits

The versatility and critical importance of the shale shaker screen are best understood through its diverse application scenarios and the significant operational advantages it delivers across various drilling and solids separation industries. Primarily, these screens are indispensable in the oil and gas sector, particularly for conventional drilling, unconventional shale gas exploration, and intricate horizontal directional drilling (HDD) projects. In oil and gas drilling, the shale shaker screen is the first line of defense in the solids control cascade, receiving the drilling fluid directly from the wellbore. Its primary function here is to remove large drilled cuttings before they can damage downstream equipment like centrifuges and desanders, and more critically, before they can alter the rheological properties of the drilling fluid. Efficient removal of these solids is paramount for maintaining mud weight, viscosity, and lubricity, which directly impact drilling rate of penetration (ROP), wellbore stability, and overall drilling safety. Beyond oil and gas, shale shaker screens are vital in coal bed methane (CBM) extraction, geothermal drilling, and even in certain civil engineering applications where large-scale slurry separation is required, such as tunneling or foundation drilling. Their ability to handle high flow rates and separate a wide range of particle sizes makes them adaptable to diverse fluid processing needs. The technical advantages offered by high-quality shale shaker screens are manifold and directly translate into tangible economic and environmental benefits. One of the most significant advantages is energy efficiency. By efficiently separating solids, the screen reduces the load on mud pumps and other circulation equipment, leading to lower power consumption. Furthermore, superior solids removal means less fresh drilling fluid needs to be prepared and fewer expensive additives are consumed, leading to substantial savings. Anti-corrosion properties, primarily derived from the use of premium stainless steel and advanced bonding agents, significantly extend the screen's operational life, even when exposed to aggressive drilling fluids containing chlorides, sulfides, and other corrosive agents. This longevity reduces replacement frequency and associated maintenance costs. Moreover, efficient solids control drastically minimizes drilling fluid losses. By recovering a higher percentage of reusable drilling fluid, the overall cost of mud management is reduced, and the volume of waste requiring disposal is substantially lowered. This not only presents an economic benefit but also contributes significantly to environmental compliance and sustainability efforts. Reduced fluid loss also means less environmental impact from waste disposal, which is increasingly regulated worldwide. Another critical advantage is improved ROP. Cleaner drilling fluid translates to less wear on drill bits, allowing them to operate at peak efficiency for longer durations, which in turn accelerates drilling progress. The Hook Strip Flat Screen, with its optimized design for maximum non-blanked area and superior fluid conductance, embodies these advantages, ensuring effective separation of drilling solids, minimizing mud loss, and extending screen life even in the most challenging drilling environments. Its robust construction and precise mesh configuration are engineered to withstand the rigorous conditions encountered during deep well and horizontal drilling, contributing to a more sustainable and economically viable drilling operation. By consistently delivering clean drilling fluid back to the wellbore, these screens play a crucial role in preventing differential sticking, minimizing formation damage, and improving the overall stability of the borehole, thereby enhancing drilling safety and operational reliability.

Navigating the Global Shale Shaker Screen Price Landscape and Market Trends

Understanding the factors that influence shale shaker screen price is crucial for procurement managers and drilling operators seeking to optimize their budget without compromising performance. The price of a shale shaker screen is a complex function of several interconnected variables, reflecting both the intrinsic value of the product and the dynamic forces of the global market. Primarily, the cost is driven by the quality and type of raw materials used. Screens constructed from premium-grade stainless steel (e.g., SUS316 for enhanced corrosion resistance) and advanced composite frame materials will naturally command a higher price than those made from lower-grade or standard materials. The number of mesh layers and the complexity of the mesh configuration—such as multi-layered, corrugated, or pyramid designs that offer increased non-blanked area and improved fluid handling—also significantly impact the manufacturing cost. More sophisticated designs require higher precision manufacturing processes and often more material, translating to a higher unit price. Furthermore, the brand reputation and the manufacturer's commitment to research and development play a role; established brands known for their consistent quality, innovation, and adherence to international standards like API RP 13C often price their products commensurate with their perceived value and reliability. The volume of the order is another critical factor influencing the per-unit shale shaker screen price; larger bulk orders typically benefit from economies of scale, leading to lower per-unit costs compared to smaller, bespoke orders. Beyond these intrinsic factors, the global market for shale shaker screens is influenced by broader industry trends. The volatility of crude oil and natural gas prices directly impacts drilling activity, which in turn affects demand for solids control equipment. Increased drilling, especially in technically challenging unconventional plays, drives demand for high-performance screens, potentially impacting pricing. Technological advancements, such as the development of longer-lasting or more efficient screen designs, can also shift market dynamics. Regional variations in labor costs, material sourcing, and logistics significantly contribute to the final shale shaker screen price in different parts of the world. For instance, screens sourced from a shale shaker screen China factory might offer a competitive price point due to efficient manufacturing scales and lower labor costs, while those from North American or European manufacturers might reflect higher material or processing costs. However, it is essential to look beyond the initial price tag and consider the total cost of ownership (TCO), which includes aspects like screen lifespan, efficiency in solids removal (reducing drilling fluid loss), and impact on downstream equipment wear. A marginally more expensive, higher-quality screen that lasts twice as long and performs more efficiently can deliver substantial long-term savings by reducing replacement frequency, minimizing drilling fluid consumption, and extending the operational life of expensive drilling machinery. In essence, while the initial shale shaker screen price is an important consideration, the true value lies in the screen's performance, durability, and its contribution to overall drilling efficiency and cost reduction over the entire drilling campaign. Forward-thinking operators prioritize value over mere cost, understanding that a robust solids control system anchored by high-quality screens is an investment that yields significant returns in operational uptime, reduced waste, and enhanced environmental compliance.

Choosing the Right Partner: Global Insights into Shale Shaker Screen China and Beyond

In the globalized market, selecting the right supplier for shale shaker screens requires careful consideration, extending beyond mere product specifications to encompass manufacturing capabilities, quality assurance, and supply chain reliability. The rise of shale shaker screen China manufacturers has significantly reshaped the global supply landscape, offering a compelling blend of cost-effectiveness and increasing technological sophistication. China has become a major hub for manufacturing high-quality industrial products, leveraging advanced production technologies, competitive labor costs, and a robust supply chain for raw materials. This allows Chinese manufacturers to offer shale shaker screens that often present a highly competitive shale shaker screen price without compromising on essential performance attributes. However, when evaluating a shale shaker screen factory, buyers must prioritize several key criteria to ensure consistent quality and reliability. Firstly, certifications are paramount: look for manufacturers adhering to international standards such as ISO 9001 for quality management systems and, most critically for this industry, API RP 13C compliance for screen performance evaluation. These certifications provide objective evidence of a factory's commitment to rigorous quality control and product excellence. Secondly, examine the factory's production capabilities, including the use of advanced manufacturing processes like automated weaving, precision welding, and state-of-the-art bonding techniques that ensure the durability and dimensional accuracy of the screens. A technologically advanced shale shaker screen factory will invest in equipment that guarantees consistent mesh tension, proper bonding of layers, and robust frame construction. Thirdly, consider the manufacturer's experience and reputation in the industry. A factory with a long track record of serving the oil and gas sector will have a deeper understanding of specific drilling challenges and the evolving needs of operators. Client testimonials, case studies, and references can offer valuable insights into a factory's reliability and customer service. Fourthly, evaluate their capacity for customization. As drilling projects become increasingly specialized, the ability of a shale shaker screen factory to produce custom mesh sizes, frame configurations, or specialized materials to meet unique operational requirements is a significant advantage. Finally, assess their supply chain and logistics capabilities. A reliable partner will have efficient processes for order fulfillment, packaging, and international shipping to ensure timely delivery and minimize transit damage. While geographical proximity might sometimes influence choice, the global availability of high-quality products from a shale shaker screen China factory that meets these stringent criteria often outweighs the benefits of local sourcing, particularly when considering the balance of cost, quality, and proven performance. Our Hook Strip Flat Screens are manufactured to meet these global benchmarks, combining competitive pricing with uncompromised quality, ensuring that operators receive a reliable product that integrates seamlessly with their existing solids control systems and contributes to enhanced drilling efficiency worldwide.

Typical Specifications: Hook Strip Flat Screen

Tailored Solutions and Unwavering Support for Your Shale Shaker Screen Needs

Recognizing that no two drilling projects are exactly alike, a key differentiator for leading shale shaker screen suppliers is their capacity to offer comprehensive customization solutions and robust customer support. While standard Hook Strip Flat Screens are designed to fit a wide range of shaker models and operational requirements, specific drilling conditions—such as highly abrasive formations, extremely high flow rates, or unique mud chemistries—may necessitate tailored screen solutions. Customization options extend to various critical parameters. This includes bespoke mesh configurations, where the number of layers, wire diameter, and mesh aperture sizes can be precisely engineered to achieve an optimal balance of conductance and cut point for specific drilling fluid properties and solids characteristics. For instance, a project encountering very fine, reactive clays might benefit from a screen with a slightly different pore geometry to minimize blinding, while drilling through hard rock formations might require mesh with enhanced abrasion resistance. Frame configurations can also be customized to ensure perfect compatibility with older or specialized shaker models that deviate from standard dimensions. This flexibility in design ensures that operators do not have to compromise on efficiency due to equipment constraints. Material customization is another area, allowing for the use of specialized alloys or polymer composites for frames and mesh when extreme temperatures, highly corrosive environments, or specific weight restrictions are in play. Beyond the product itself, the quality of technical support and after-sales service is paramount for maximizing the operational lifespan and efficiency of any shale shaker screen. This includes expert guidance on screen selection, installation best practices, and troubleshooting common issues like blinding or tearing. Reputable suppliers provide comprehensive technical documentation, online resources, and direct access to experienced engineers who can offer real-time advice. Delivery cycles are also a critical aspect of trustworthiness and efficiency in the B2B supply chain. A streamlined logistics process ensures that screens are delivered promptly to the wellsite, minimizing potential downtime. Suppliers often leverage global distribution networks and optimized inventory management to meet urgent demands. Furthermore, a strong warranty commitment provides essential peace of mind, assuring buyers of the product's quality and the manufacturer's accountability. A transparent warranty policy covering manufacturing defects and premature failure under normal operating conditions demonstrates confidence in the product's durability and design. Our commitment extends beyond merely supplying shale shaker screens; we aim to be a long-term partner, offering ongoing support, technical consultation, and customized solutions that evolve with your drilling challenges. We understand that effective solids control is a dynamic process, and our team is dedicated to helping clients optimize their systems through continuous improvement and responsive service. This holistic approach, combining high-quality customizable products with unwavering support, ensures that our Hook Strip Flat Screens not only meet but exceed the demanding expectations of modern drilling operations, contributing significantly to operational uptime, reduced costs, and improved environmental performance throughout the entire drilling lifecycle. Our global reach and agile manufacturing capabilities enable us to deliver tailored solutions rapidly, supporting drilling projects across diverse geographies and operational scales.

Proven Performance: Real-World Shale Shaker Screen Application Cases

The true testament to a shale shaker screen's quality and effectiveness lies in its proven performance in demanding real-world drilling environments. Our Hook Strip Flat Screens have consistently demonstrated their superiority in various challenging applications, delivering tangible benefits and exceeding client expectations. These application cases underscore the product's robustness, efficiency, and significant contribution to operational success.

Case Study 1: Enhanced Efficiency in Offshore Drilling Operations

An offshore drilling operator in the North Sea faced persistent challenges with premature shale shaker screen wear and excessive drilling fluid loss due to highly abrasive cuttings and high flow rates encountered in deepwater formations. Their existing screens frequently blinded and tore, leading to increased screen consumption, costly mud additions, and prolonged non-productive time for screen changes. Our technical team collaborated with the operator to understand their specific fluid properties and drilling parameters. We recommended implementing our Hook Strip Flat Screens with a specialized high-abrasion-resistant mesh configuration and reinforced composite frames, tailored to withstand the extreme conditions. The results were remarkable:

- Screen lifespan increased by an average of 45%, significantly reducing screen replacement frequency and associated labor costs.

- Drilling fluid loss through the shaker was reduced by 18%, leading to substantial savings in mud chemicals and disposal volumes.

- Overall solids removal efficiency improved, contributing to a 5% increase in the rate of penetration (ROP) by maintaining cleaner drilling fluid.

- The crew reported easier and faster screen changes due to the Hook Strip design, further minimizing downtime.

Case Study 2: Optimized Solids Control in Unconventional Shale Gas Drilling

A major energy company operating in a prolific shale play in North America faced challenges with solids management during horizontal drilling. The fine, reactive shale cuttings, combined with high-viscosity drilling fluids, led to frequent screen blinding and reduced shaker capacity, impacting their ability to maintain optimal mud rheology and necessitating frequent fluid disposal. We proposed a phased approach, initially replacing their existing screens with our Hook Strip Flat Screens featuring a multi-layered, high-conductance mesh designed specifically for fine solids separation in viscous fluids. The advanced mesh design and precise tensioning allowed for superior fluid handling without compromising on the cut point, effectively combating blinding.

- The screen's ability to process higher volumes of drilling fluid resulted in a 20% increase in shaker processing capacity, allowing for faster drilling rates.

- Blinding issues were dramatically reduced, leading to consistent solids removal and better maintenance of drilling fluid properties.

- The volume of wet cuttings requiring disposal decreased by 15%, translating into substantial savings on waste management and a reduced environmental footprint.

- Operators reported enhanced clarity of the drilling fluid, leading to improved downhole tool performance and reduced non-productive time from tool failures.

FAQs About Shale Shaker Screens

To further assist our clients and industry professionals, we've compiled answers to some of the most frequently asked questions regarding shale shaker screens. These insights aim to provide clarity on selection, operation, and maintenance, ensuring optimal performance and longevity for your solids control equipment.

Q: How do I choose the correct mesh size for my shale shaker screen?

A: The ideal mesh size for your shale shaker screen depends on several critical factors, including the characteristics of your drilling fluid (mud weight, viscosity, rheology), the expected drill cuttings size and formation type, and the desired drilling rate. Typically, a coarser screen (lower API mesh number) is used in the initial stages of drilling to handle larger cuttings and higher flow rates, followed by progressively finer screens (higher API mesh number) in subsequent stages to remove smaller solids and maintain mud integrity. Consulting with our technical experts and providing detailed information about your drilling program can help precisely determine the most effective screen combination to optimize solids removal efficiency and maximize drilling performance. Factors such as screen conductance and cut point (D100), as defined by API RP 13C, are paramount in this selection process, ensuring that the screen effectively removes undesirable solids while minimizing the loss of valuable drilling fluid. An accurate selection process is crucial for minimizing the shale shaker screen price over the long term by reducing replacement needs and optimizing fluid recovery.

Q: What is the typical service life of a shale shaker screen?

A: The service life of a shale shaker screen is highly variable and influenced by a multitude of factors, including the abrasiveness of drill cuttings, the flow rate of drilling fluid, the operational parameters of the shale shaker (e.g., vibration intensity, G-force), proper installation and maintenance practices, and the quality of the screen itself. High-quality screens, like our Hook Strip Flat Screen, designed with robust frames and durable mesh materials, are engineered for extended operational life even under harsh conditions. While it's difficult to provide an exact figure due to these variables, screens are typically replaced based on visual inspection for wear, tearing, or blinding, or when a significant drop in solids separation efficiency is observed. Regular cleaning, proper storage, and adherence to recommended operating procedures can significantly prolong the lifespan of your shale shaker screen, reducing replacement frequency and overall operational costs. The durability of our screens helps optimize your overall shale shaker screen price per hour of operation.

Q: Are your shale shaker screens compatible with all major shaker brands?

A: Yes, our comprehensive range of shale shaker screens, including the Hook Strip Flat Screen, is designed for broad compatibility with most leading shale shaker models from major manufacturers such as Derrick, Brandt (NOV), MI SWACO, and FLC. We understand the diverse equipment landscape in the drilling industry and engineer our screens to meet or exceed OEM specifications for fit, form, and function. Each screen type is precisely dimensioned and designed with specific hook strip configurations or frame designs to ensure a perfect fit and optimal performance on the intended shaker unit. We encourage customers to provide their shaker model details during the inquiry process to ensure we recommend the exact compatible screen that integrates seamlessly with their existing solids control equipment, ensuring maximum efficiency and minimal operational disruption. Our expertise as a leading shale shaker screen factory ensures seamless integration.

Q: How does the quality of a shale shaker screen impact drilling fluid costs?

A: The quality of a shale shaker screen directly impacts drilling fluid costs in several significant ways. A superior-quality screen, characterized by optimal conductance and a precise cut point, ensures highly efficient removal of undesirable drilled solids while minimizing the loss of valuable drilling fluid. Screens with poor construction or inconsistent mesh can lead to premature blinding, reduced processing capacity, and excessive drilling fluid carryover into the waste stream, necessitating more frequent fluid replenishment. Conversely, a high-performance shale shaker screen maximizes fluid recovery, extends the lifespan of the drilling fluid, reduces the volume of solid waste requiring disposal, and lowers the consumption of costly fluid additives. Investing in high-quality screens, therefore, translates into substantial savings in drilling fluid expenses, contributes to environmental compliance, and enhances overall drilling economics by maintaining fluid properties more effectively. This long-term cost-saving demonstrates that the initial shale shaker screen price is a minor factor compared to operational savings.

Q: What certifications should I look for when purchasing shale shaker screens?

A: When purchasing shale shaker screens, looking for specific certifications ensures you are acquiring a product that adheres to recognized industry standards for quality, performance, and safety. Key certifications and compliance standards to consider include API RP 13C (Recommended Practice for Drilling Fluid Processing Systems Evaluation), which is crucial for evaluating and comparing screen performance metrics such as conductance and cut point. ISO 9001 (Quality Management System) indicates that the manufacturer operates under a robust quality management framework, ensuring consistency and reliability in their production processes. Additionally, certifications related to environmental management (ISO 14001) or occupational health and safety (ISO 45001) can provide further assurance regarding the manufacturer's commitment to responsible and ethical practices. Always request and verify these certifications to ensure the shale shaker screen meets the stringent requirements of modern drilling operations and international trade. This due diligence ensures you are partnering with a reputable shale shaker screen factory.

Driving Efficiency and Sustainability with Advanced Shale Shaker Screen Technology

The journey through the intricate world of shale shaker screens reveals their indispensable role in modern drilling and solids control operations. From their meticulous manufacturing process, leveraging advanced materials and precision engineering, to their critical function in optimizing drilling fluid properties and minimizing environmental impact, shale shaker screens are far more than simple filtration devices. They are sophisticated tools that directly influence operational efficiency, safety, and profitability across the energy sector. The dynamic market, characterized by evolving drilling techniques and increasingly stringent environmental regulations, continues to drive innovation in shale shaker screen mesh design and frame technology. Choosing the right screen, therefore, requires a comprehensive understanding of technical specifications, performance metrics like API RP 13C compliance, and the long-term value offered by a reliable shale shaker screen factory, rather than solely focusing on the immediate shale shaker screen price. Investments in high-quality screens, such as our Hook Strip Flat Screen, translate into tangible benefits: reduced drilling fluid consumption, extended equipment lifespan, minimized waste disposal costs, and ultimately, a more sustainable and economically viable drilling program. As the global energy landscape continues to evolve, the demand for high-performance solids control solutions will only intensify, solidifying the shale shaker screen's position as a foundational component in achieving operational excellence and environmental stewardship. By partnering with a manufacturer committed to innovation, quality, and comprehensive support, drilling operators can ensure their solids control systems are robust, efficient, and future-ready. Our dedication to delivering superior shale shaker screen technology, backed by rigorous quality assurance and unparalleled customer service, positions us as a trusted leader in supporting your most demanding drilling projects worldwide. We are committed to pushing the boundaries of what is possible in solids control, ensuring that our clients consistently achieve cleaner mud, longer screen life, and superior operational outcomes.

References and Further Reading

- American Petroleum Institute (API) - Drilling Fluids Standards (General reference for API RP 13C and related practices).

- Society of Petroleum Engineers (SPE) - Technical Papers on Solids Control (Relevant research on drilling fluid processing and solids separation).

- International Organization for Standardization (ISO) - ISO 9001 Overview (Information on quality management systems applicable to manufacturing processes).

- Drilling Contractor Magazine - Solids Control Section (Industry articles and insights on solids control technologies and trends).

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025