- صنعتي زون، Anping ٽائون جي ڏکڻ، Hengshui، Hebei، چين.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  انگريزي

انگريزي  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- انگريزي

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

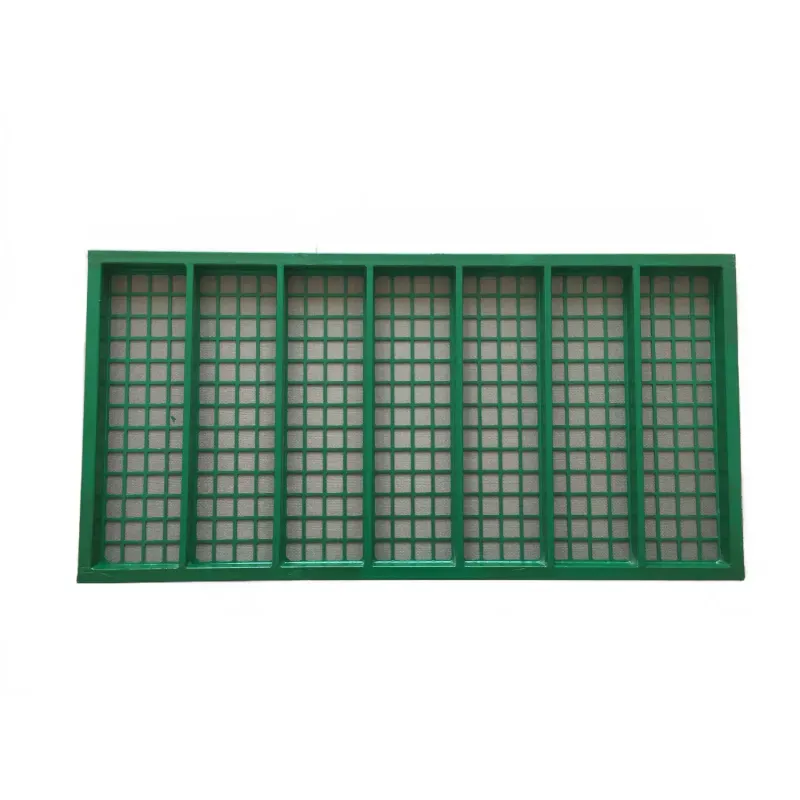

Best Shale Shaker Screen for Sale

When it comes to separating solids from drilling fluids, the right equipment is everything. If you’re in the oil and gas industry, construction, or any drilling-intensive sector, having access to a top-quality shale shaker screen for sale is essential. These screens are the first line of defense in the solid control system, working as a filter that removes large solids from the drilling fluid before it circulates back into the borehole. Without efficient shale shaker screens, drilling fluid quickly becomes contaminated, causing wear on equipment, higher operating costs, and unnecessary downtime.

A durable, high-performance shale shaker screen for sale will enhance your overall drilling operation by reducing mud losses and preserving the integrity of your equipment. Whether you’re managing a shallow well or working deep offshore, choosing the right screen can increase fluid recycling efficiency and reduce environmental impact.

Today’s most advanced shale shaker screen for sale options feature multilayered mesh technology, corrosion-resistant frames, and easy-to-install configurations that minimize rig time. Investing in a premium screen means less screen replacement, better cuttings disposal, and longer life for your drilling fluids.

What Makes a Shale Shaker Screen Indispensable in Drilling Operations

The shale shaker screen plays a critical role in the solid control process. Installed on shale shakers—vibratory devices that separate solids from fluids—these screens determine the efficiency of the separation. Drilling fluid, or mud, is directed over the screen, where it passes through while solid cuttings are retained and discarded. The effectiveness of this process depends entirely on the shale shaker screen design, quality, and material.

High-performance shale shaker screens help reduce the overall volume of drilling waste. This not only saves money in disposal costs but also allows the reclaimed fluid to be reused—an essential feature in environmentally regulated operations. A properly selected shale shaker screen contributes directly to the system’s mud recovery rate and ensures consistent performance in both water-based and oil-based mud environments.

There are various types of shale shaker screens—including hook strip, frame type, and soft screen designs—all engineered for specific rig types and fluid compositions. The mesh size, often expressed in API numbers, defines the screen’s filtration ability. A finer mesh size increases fluid clarity but may reduce flow rate, which is why selecting the right screen requires understanding the drilling conditions and expected solids load.

Top Shale Shakerscreen Manufacturers Setting Global Industry Standards

With increasing demand for high-performance solid control systems, shale shakerscreen manufacturers are pushing the boundaries of design, material science, and precision engineering. Global leaders in this segment offer custom-manufactured screens that can meet extreme drilling environments, high-volume separation needs, and rapid replacement cycles. Choosing from reputable shale shakerscreen manufacturers is essential to ensure operational reliability, extended screen life, and consistent filtration.

Top-tier shale shakerscreen manufacturers utilize advanced materials like stainless steel wire mesh, polyurethane, and rubber frames to create screens that can endure aggressive fluids and mechanical wear. Some manufacturers also integrate high-strength composite frames that resist warping and degradation under heat and vibration, significantly increasing screen longevity.

In addition to superior product design, industry-leading shale shakerscreen manufacturers invest in strict quality control systems and certifications. ISO, API RP 13C, and other international standards are followed rigorously to ensure that each screen performs precisely as required. With supply chains that stretch globally, the best manufacturers provide fast delivery, technical support, and inventory management to reduce downtime and improve field responsiveness.

Collaborating with proven shale shakerscreen manufacturers also ensures compatibility with various shaker brands such as Derrick, NOV, MI-SWACO, and more. This guarantees a seamless fit and integration with existing equipment, preventing costly retrofits or operational inefficiencies.

Understanding Shale Shaker Screen Material for Optimal Performance

The performance and durability of a shale shaker screen are largely determined by the shale shaker screen material used in its construction. The right material choice directly impacts the screen’s resistance to wear, corrosion, and separation efficiency. Most commonly, screens are fabricated using stainless steel wire mesh layered over a support frame, often made from steel or composite materials.

The shale shaker screen material must strike a delicate balance between fine filtration and fluid flow rate. High-grade stainless steel mesh provides precise particle separation while resisting rust and fatigue. Multilayered mesh configurations improve strength and allow for gradual degradation, which extends screen usability even under aggressive drilling conditions.

Composite frames have become increasingly popular in recent years. These frames offer superior vibration resistance, reduced weight, and high thermal stability. Unlike traditional metal frames, composite materials resist bending, cracking, and corrosion, even after prolonged exposure to oil-based fluids.

Some screens also incorporate polyurethane coatings or flexible rubber edges to increase sealing performance and prevent fluid bypass. Selecting the ideal shale shaker screen material means understanding the type of drilling fluid in use, the nature of the cuttings, the desired recovery rate, and the overall wear cycle of your drilling operation.

Engineers today look beyond price and mesh count; they evaluate resistance to tear, mesh bonding methods, open area percentages, and tensile strength to choose the optimal shale shaker screen material for their unique drilling environments.

Where to Find Reliable Shale Shaker Screen for Sale at Competitive Prices

Finding the right shale shaker screen for sale is more than a procurement decision—it’s a performance investment. While the market is full of suppliers offering various screen types and prices, discerning buyers look for quality, compatibility, and after-sales support. Price alone should not dictate your decision when long-term savings and screen reliability are at stake.

Reputable suppliers of shale shaker screen for sale will provide detailed technical specifications, including mesh type, API designation, material composition, and lifespan estimates. Some also offer performance simulations or field data to help drilling engineers make informed choices. Fast delivery and warehousing are also critical, as delays in screen replacement can bring an entire rig to a standstill.

Competitive pricing is achievable without sacrificing quality if you work directly with original shale shakerscreen manufacturers or their authorized distributors. These partnerships often come with bulk discounts, technical training, and custom solutions for specific shale shaker models. Whether your project is onshore or offshore, investing in the right shale shaker screen for sale means more efficient fluid handling, less downtime, and reduced environmental footprint.

shale shaker screen FAQs

What is a shale shaker screen used for in drilling operations?

A shale shaker screen is used to separate solid particles from drilling fluids. It sits on a vibrating device called a shale shaker, and as the fluid passes over it, solids are retained while clean fluid is recirculated. This process is essential for maintaining the efficiency of the drilling operation and prolonging equipment lifespan.

How do I choose the right shale shaker screen material?

Selecting the right shale shaker screen material depends on your drilling fluid (oil-based or water-based), particle sizes, and operating conditions. Stainless steel is commonly used for its durability and corrosion resistance. For harsh environments, consider composite frames and multilayered mesh for added strength and longer life.

What is the typical lifespan of a shale shaker screen?

The lifespan of a shale shaker screen varies based on material, mesh type, drilling conditions, and maintenance. On average, screens can last from 20 to 100 drilling hours. High-quality screens made by leading shale shakerscreen manufacturers with composite frames and advanced bonding technology usually last longer than low-cost alternatives.

Are all shale shaker screens interchangeable between different shakers?

Not all shale shaker screens are universally compatible. Screens are often designed for specific shale shaker models and brands. However, many shale shakerscreen manufacturers produce replacement screens that match major shaker types like Derrick, NOV, or MI-SWACO. Always confirm compatibility before purchasing.

Where can I find high-quality shale shaker screen for sale with fast delivery?

You can find top-quality shale shaker screen for sale from trusted global suppliers and manufacturers who specialize in solid control systems. Look for companies that provide certifications, product data sheets, and customer support. Direct purchases from shale shakerscreen manufacturers often ensure better pricing, customization, and technical assistance.

-

Upgrade Your Industrial Operations with Durable Steel GratingخبرونJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingخبرونJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsخبرونJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsخبرونJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingخبرونJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsخبرونJul.21,2025