- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 17, 2025 19:26

Back to list

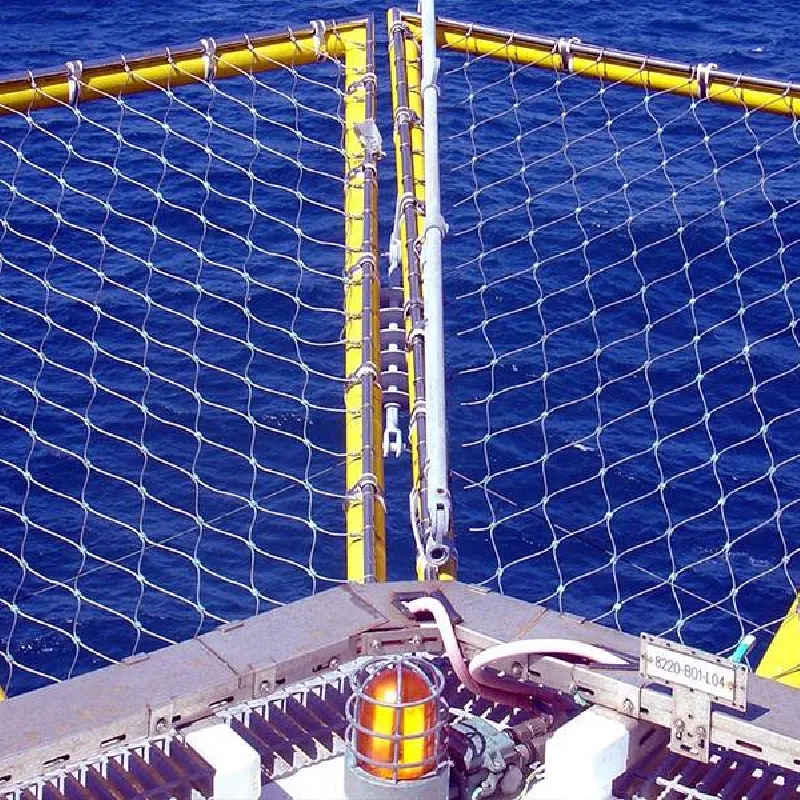

helideck perimeter safety nets

Enhancing safety measures on helidecks is a primary concern within the aerospace and offshore industries. The helideck safety net, a crucial component, plays a vital role in preventing accidents and ensuring safe operations. Drawing from industry experience, this article aims to delve into the expertise required in designing these nets, establishing their efficacy, and why they are a cornerstone of trust in aviation safety systems.

Authoritativeness in the industry is closely related to compliance with safety standards established by authoritative bodies such as the International Civil Aviation Organization (ICAO) and the International Maritime Organization (IMO). Organizations that design and manufacture helideck safety nets are governed by these standards, ensuring these safety mechanisms meet the strict requirements for stress and wind resistance. By adhering to these standards, manufacturers not only gain a competitive edge in the market but also assure operators of their commitment to safety and quality. Trustworthiness is further established through rigorous testing procedures. Prior to deployment, every helideck safety net undergoes extensive testing to ensure its resilience against the dynamic forces experienced during helicopter landing and take-off. Simulations replicating extreme weather conditions and emergency situations validate the net's functionality. This commitment to quality assurance fosters trust among operators, pilots, and passengers, as they can be confident in the measures in place to safeguard their safety. In conclusion, the integration of helideck safety nets underscores the industry's dedication to safety and operational excellence. By leveraging experience, expertise, and a commitment to authoritative standards, these nets stand as a reliable safety solution. The ongoing innovation and adherence to quality checks not only respond to the immediate needs of operators but proactively address potential future challenges in aerial transport safety. For industry stakeholders, investing in high-quality helideck safety nets is not just a regulatory compliance matter but a testament to robust safety culture—a culture that prioritizes human lives above all else.

Authoritativeness in the industry is closely related to compliance with safety standards established by authoritative bodies such as the International Civil Aviation Organization (ICAO) and the International Maritime Organization (IMO). Organizations that design and manufacture helideck safety nets are governed by these standards, ensuring these safety mechanisms meet the strict requirements for stress and wind resistance. By adhering to these standards, manufacturers not only gain a competitive edge in the market but also assure operators of their commitment to safety and quality. Trustworthiness is further established through rigorous testing procedures. Prior to deployment, every helideck safety net undergoes extensive testing to ensure its resilience against the dynamic forces experienced during helicopter landing and take-off. Simulations replicating extreme weather conditions and emergency situations validate the net's functionality. This commitment to quality assurance fosters trust among operators, pilots, and passengers, as they can be confident in the measures in place to safeguard their safety. In conclusion, the integration of helideck safety nets underscores the industry's dedication to safety and operational excellence. By leveraging experience, expertise, and a commitment to authoritative standards, these nets stand as a reliable safety solution. The ongoing innovation and adherence to quality checks not only respond to the immediate needs of operators but proactively address potential future challenges in aerial transport safety. For industry stakeholders, investing in high-quality helideck safety nets is not just a regulatory compliance matter but a testament to robust safety culture—a culture that prioritizes human lives above all else.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025