- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

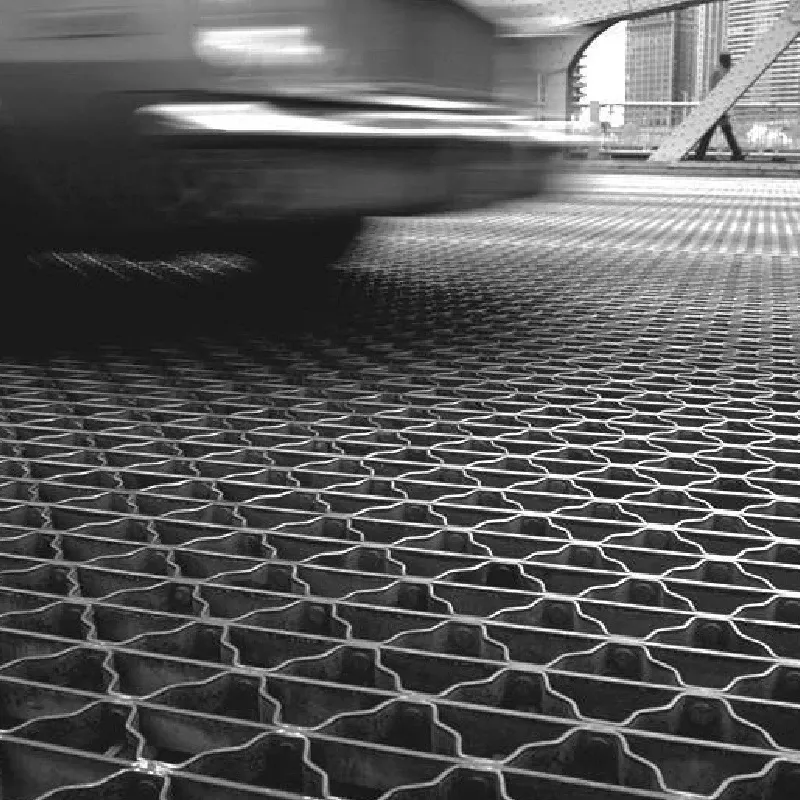

grating floor plate

Understanding Grating Floor Plates Their Importance and Applications

Grating floor plates, commonly referred to as grating or grid plates, are essential components in various industrial and commercial environments. Their design and functionality make them ideal for applications where strength, safety, and efficiency are paramount. Composed of metal or fiberglass, these plates offer a perforated surface that provides excellent load-bearing capacity while allowing for drainage, light, and ventilation.

One of the most prominent features of grating floor plates is their ability to enhance safety in the workplace. In industrial settings, where spills are frequent and materials can be hazardous, these plates help prevent slips and falls. The open design allows liquids to flow through, minimizing the risk of pooling and creating slippery surfaces. Moreover, the robust materials used in manufacturing grating plates ensure that they can withstand heavy machinery and foot traffic, providing a stable surface for workers.

Grating floor plates come in various types, including steel, aluminum, and fiberglass. Each material has its unique advantages. For example, steel grating is known for its strength and durability, making it suitable for heavy industrial applications. Aluminum, on the other hand, is lighter and resistant to corrosion, making it ideal for outdoor environments and areas exposed to moisture. Fiberglass grating is particularly valuable in chemical industries due to its resistance to harsh chemicals and its non-conductive properties.

The versatility of grating floor plates is another significant advantage. They can be customized to fit various applications, from walkways and platforms to flooring in power plants, water treatment facilities, and manufacturing plants. This adaptability makes grating a popular choice in a wide range of industries, including construction, mining, shipbuilding, and food processing.

grating floor plate

Installation of grating floor plates is typically straightforward, allowing for quick deployment in existing structures or new builds

. They can be fabricated to specific sizes and shapes, ensuring a perfect fit for any project. This ease of installation minimizes downtime in industrial settings and helps businesses maintain operational efficiency.Moreover, grating floor plates contribute to the overall aesthetic of a space. Available in various patterns and finishes, they can blend seamlessly with architectural designs while providing functional benefits. The choice of material and finish can enhance the appearance of areas like commercial buildings, exhibition spaces, and outdoor settings.

Maintenance is another crucial aspect of grating floor plates. Regular inspections can ensure that any wear or damage is addressed promptly. The open nature of the grating allows for easy cleaning, as debris can fall through the gaps without accumulating on the surface. This feature is particularly beneficial in environments where hygiene is critical, such as food processing facilities.

In summary, grating floor plates are integral to safety, efficiency, and aesthetics in various industries. Their strength and versatility make them suitable for a multitude of applications, while their design enhances safety and minimizes maintenance. As industries continue to evolve, the importance of effective flooring solutions like grating floor plates will only grow, ensuring that workplace environments remain safe and functional. These plates not only serve practical purposes but also contribute to overall operational success in today’s fast-paced industrial landscape.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025