- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

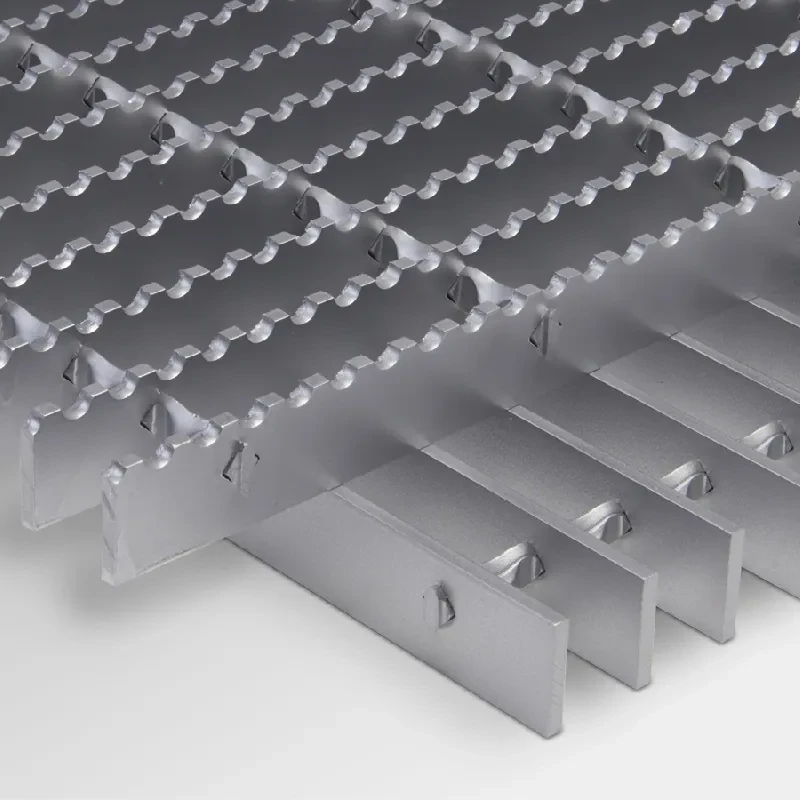

1 bar grating

Understanding 1% Bar Grating A Versatile Solution in Engineering

In the realm of engineering and construction, bar grating plays a critical role in facilitating various applications, particularly in the fields of flooring, walkways, and drainage systems. One of the emerging trends in this domain is the use of 1% bar grating, which offers a unique balance of strength, weight, and cost-effectiveness.

What is 1% Bar Grating?

1% bar grating refers to a type of metal grid consisting of load-bearing bars arranged in a parallel pattern, typically spaced at regular intervals. The term 1% generally denotes the percentage of open space versus solid material in the grating, allowing for optimal drainage while providing adequate support. This configuration is particularly beneficial in environments where water drainage is critical, such as industrial facilities, outdoor walkways, and wastewater treatment plants.

Applications and Benefits

One of the primary advantages of 1% bar grating is its lightweight design. Despite its strength, this type of grating is easier to handle and install compared to heavier alternatives, ultimately reducing labor costs. Additionally, the 1% opening allows for high water flow rates while maintaining structural integrity. This is crucial in preventing water accumulation and slip hazards, making it an excellent choice for public spaces and industrial settings alike.

1 bar grating

The versatility of 1% bar grating extends across various industries, from oil and gas to food processing and pharmaceuticals. In oil and gas installations, for instance, it is crucial for platforms and walkways due to its durability against harsh weather conditions and exposure to chemicals. In food processing plants, the open design allows for easy cleaning and sanitation, ensuring that hygiene standards are maintained.

Materials and Manufacturing

1% bar grating is typically made from strong materials such as stainless steel, aluminum, or carbon steel, depending on the application requirements. Each material offers distinct benefits—stainless steel is highly resistant to corrosion, making it ideal for outdoor and harsh environments, while aluminum provides an excellent strength-to-weight ratio, appealing for lightweight structures.

Manufacturing processes for bar grating often involve welding and precision cutting to ensure that the bars maintain their structural integrity while providing the necessary openings. Advances in technology have allowed for customization, enabling engineers and designers to tailor the grating to specific dimensions and load requirements.

Conclusion

In summary, 1% bar grating emerges as a robust and practical solution for a variety of engineering applications. Its combination of strength, lightweight design, and efficient water drainage capabilities make it a favored choice in both industrial and commercial settings. As the demand for effective and versatile materials continues to rise, bar grating will undoubtedly remain a key element in the design and implementation of safe, reliable structures. Whether for pedestrian walkways, industrial platforms, or drainage systems, 1% bar grating exemplifies the innovation found within modern engineering practices.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025