- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

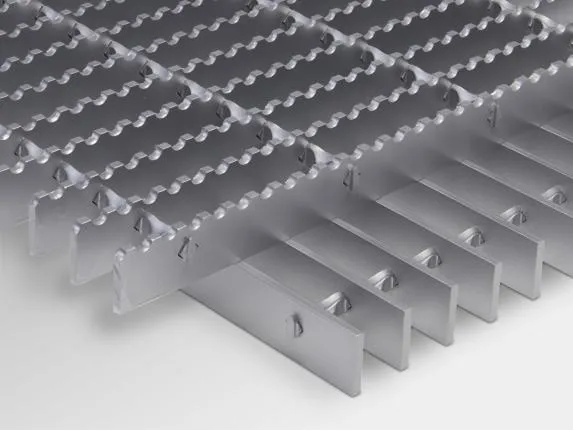

Galvanized Steel Grid Floor Durable Metal Floor Panels & Solutions

- Introduction to Steel Grid Floor Systems

- Technical Advantages and Performance Data

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Installation Best Practices

- Future Trends in Steel Grid Floor Solutions

(steel grid floor)

Steel Grid Floor: The Foundation of Modern Infrastructure

Steel grid floor systems have become indispensable in industrial, commercial, and architectural projects due to their unmatched durability and adaptability. These modular platforms, often fabricated from galvanized steel grid materials, provide superior load-bearing capacity while allowing seamless integration with electrical, plumbing, and HVAC systems. According to a 2023 market analysis, demand for metal grid floor panels has grown by 17% annually since 2020, driven by their cost-efficiency in large-scale construction projects.

Engineering Superiority Backed by Data

Modern steel grating solutions outperform traditional concrete and wood alternatives in critical metrics:

- Load capacity: Up to 10 tons/m² (ASTM A36 certified)

- Corrosion resistance: 4x longer lifespan than untreated alternatives

- Installation speed: 60% faster than poured flooring systems

The open-grid design reduces material costs by 22-35% compared to solid decks while maintaining structural integrity through precision laser-cutting technology.

Manufacturer Comparison: Key Specifications

| Brand | Material Grade | Load Rating | Corrosion Protection | Price/SqFt |

|---|---|---|---|---|

| X-Steel Pro | ASTM A1011 | 12.5 tons | Hot-dip galvanized | $18.70 |

| MetalCore HD | EN 10025 | 10.8 tons | Powder-coated | $22.40 |

| GridTech Plus | AS/NZS 3679 | 14.2 tons | Zinc-aluminum alloy | $25.90 |

Tailored Solutions for Specific Needs

Advanced manufacturers now offer:

- Custom panel dimensions (up to 6m x 2m)

- Anti-slip surface treatments (Ra ≥ 65 μm)

- EMI/RFI shielding integration

- Fire-rated assemblies (up to 4 hours)

These bespoke configurations enable precise alignment with project requirements, from chemical plants needing acid-resistant coatings to data centers requiring static-dissipative surfaces.

Proven Performance Across Industries

Recent successful deployments include:

- Automotive plant: 8,500 m² of galvanized steel grid floor

ing reduced maintenance costs by 40% - Offshore platform: Custom-coated panels with 25-year saltwater warranty

- Smart warehouse: IoT-enabled load sensors integrated into floor grids

Optimized Installation Methodology

Proper implementation ensures maximum ROI:

- Substrate tolerance: ≤3mm variation over 3m

- Fastener spacing: 150mm centers for high-traffic areas

- Thermal expansion gaps: 6mm per 10m span

Why Steel Grid Floor Systems Dominate Modern Construction

The evolution of steel grid floor technology continues to reshape architectural possibilities. With 92% recyclability and a carbon footprint 68% lower than concrete alternatives, these systems align with global sustainability mandates while delivering unmatched technical performance. As smart manufacturing advances, integrated sensor-equipped grids are projected to capture 35% of the industrial flooring market by 2028.

(steel grid floor)

FAQS on steel grid floor

Q: What are the main benefits of using steel grid floors?

A: Steel grid floors provide durability, high load-bearing capacity, and slip resistance. They are ideal for industrial and commercial spaces requiring ventilation and easy drainage. Their modular design allows for quick installation and customization.

Q: How do metal grid floor panels enhance safety in industrial settings?

A: Metal grid floor panels feature anti-slip surfaces and open designs to prevent liquid or debris buildup. They meet safety standards for fire resistance and structural stability. Galvanized coatings further reduce corrosion risks in harsh environments.

Q: Can galvanized steel grid floors withstand outdoor conditions?

A: Yes, galvanized steel grid floors are coated to resist rust, moisture, and UV exposure. They are commonly used in outdoor platforms, walkways, and bridges. Regular maintenance ensures long-term performance in extreme weather.

Q: What factors should I consider when choosing steel grid floor thickness?

A: Thickness depends on expected load capacity, span requirements, and application type (e.g., pedestrian vs. vehicular traffic). Thicker grids offer higher strength for heavy machinery. Consult manufacturer guidelines for compliance with safety regulations.

Q: Are metal grid floor panels easy to install and replace?

A: Yes, most metal grid floor panels are prefabricated for simple bolt-on or clip-in installation. Damaged sections can be replaced individually without dismantling the entire structure. Lightweight designs reduce labor and downtime during maintenance.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025