- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

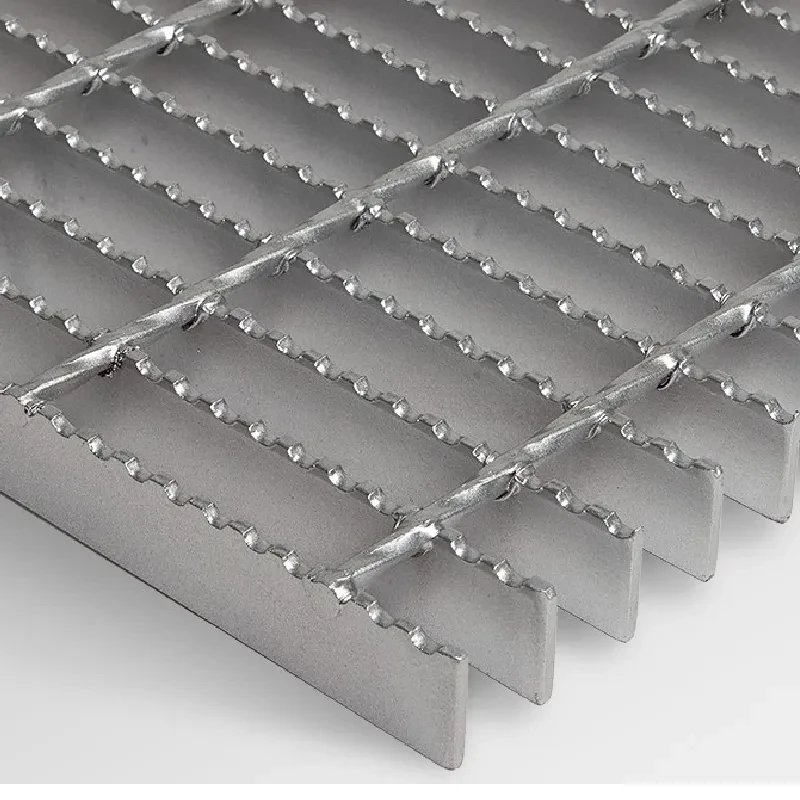

Adjustable Grating Weight with 19% W for Enhanced Performance and Stability

Understanding Grating Weights and Their Impact on Design

The world of manufacturing and design is constantly evolving, with new materials and techniques enhancing the capabilities of engineers and designers alike. Among the various elements that contribute to the efficiency and functionality of a product, weight plays a crucial role. In this context, the term grating weight, specifically at a percentage of 19% and a weight of 4 grams, encapsulates an important aspect of engineering that directly impacts design choices and product performance.

The Significance of Grating Weight

Grating weight refers to the weight associated with grating materials used in various applications, including industrial sectors, construction, and consumer products. Grating materials are used for flooring, walkways, and access points in buildings and factories. Typically made from metals such as steel or aluminum, their primary function is to provide a durable surface that can withstand heavy loads while ensuring safety and stability.

A specific weight of 4 grams at a percentage of 19% often signifies a calculated decision in product design. This weight might represent a component of a larger assembly, or it could indicate the weight distribution necessary to balance other parts of a system. In engineering, maintaining the integrity of weight distribution is critical—overly heavy components can lead to structural failures or inefficiencies, while overly light components might lack the strength or robustness needed for the intended application.

The Role of Materials in Grating Weight

The choice of materials is pivotal when discussing grating weight. Engineers often have to choose between various materials, each with its own properties regarding weight, strength, durability, and cost. For instance, choosing aluminum over steel might yield a lighter grating solution without sacrificing structural integrity. This matters especially in applications where weight is a concern—such as in aerospace or automotive industries—where every gram counts toward fuel efficiency and performance.

19 w 4 grating weight

In many cases, a weight percentage—like the 19% mentioned—can be used to assess materials in terms of their contribution to the overall structure’s weight. This percentage may denote how much of a specific component’s weight is accounted for by the grating compared to the total system weight. This evaluation is crucial during the design phase, as it allows engineers to assess trade-offs between material choices and weight, ultimately leading to a balanced and optimized product.

Practical Applications

In real-world scenarios, the implications of managing grating weight can be illustrated through an example in construction. Consider a commercial building that requires a grating for its outdoor terraces. Here, selecting the right material with an optimal weight of 4 grams—while keeping the overall weight to just 19% of the assembly—ensures that the structure remains safely within its load-bearing limits while providing a functional and aesthetically pleasing surface.

In another scenario, in the field of consumer electronics, reducing weight through advanced materials can enhance user experience. A portable device must strike a balance between being lightweight for ease of transport and maintaining enough robust structure to house delicate electronic components. Here, understanding the implications of grating weights can guide the design towards lighter yet durable alternatives.

Conclusion

In essence, discussing concepts like 19% grating weight at 4 grams unveils a broader narrative about the careful consideration that goes into product design and engineering. The interplay between weight, material choice, and application requirements contains layers of complexity that must be navigated to achieve successful outcomes. As technology continues to advance, the possibility of new materials with beneficial properties promises to revolutionize how engineers approach weight distribution and structural integrity.

In reaching for innovative solutions, designers and engineers should remember the fundamental principle of balance in their creations—ensuring that functionality, safety, and user experience are always at the forefront of their efforts. The concept of grating weight, while seemingly technical, serves as a reminder of the critical choices engineers face in crafting products that can stand the test of time while being efficient and effective. As industries continue to innovate, the emphasis on understanding weight and its ramifications will remain a key element in the design and manufacturing process.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025