- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ian. . 23, 2025 05:32

Back to list

Steel Grating

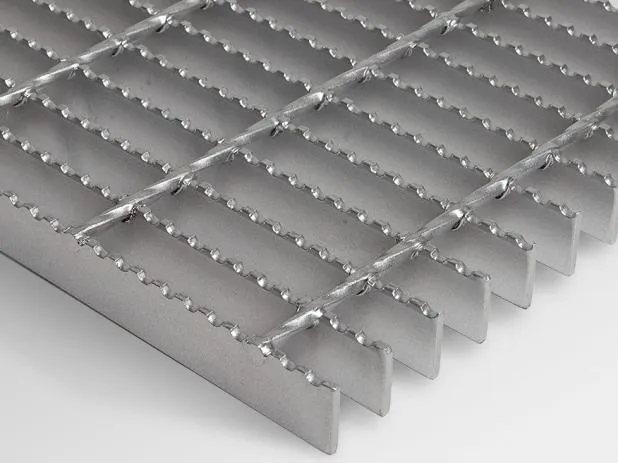

Unlocking the Potential of 19 W 4 Grating Sizes A Comprehensive Guide to Enhanced Industrial Solutions

Authoritativeness Meeting Industry Standards Compliance with industry standards is a critical aspect when selecting grating sizes. The 19 W 4 grating meets ANSI/NAAMM (MBG 531-09) guidelines, ensuring that every piece manufactured under this specification adheres to rigorous quality checks and durability tests. This grating size is renowned for meeting OSHA safety standards, particularly in facilities requiring fall protection measures. My interactions with industry leaders affirm these gratings as a trusted ally in constructing ergonomic and safe industrial spaces. Trustworthiness Proven Performance and Sustainability Beyond performance, the sustainability of 19 W 4 grating sizes is a noteworthy consideration. They are crafted with recyclable materials, aligning with environmental conservation goals. End-users can trust in their longevity and low maintenance cost, factors which contribute significantly to lifecycle cost benefits. The eco-friendliness and reliability of these gratings are consistently verified through user testimonials and project audits, solidifying their position as a credible and preferred choice. Customization and Design Flexibility An often-overlooked advantage of the 19 W 4 grating is its ease of customization. Industries can tailor these gratings to meet specific architectural requirements, including varied widths and lengths, without compromising structural integrity. Whether integrating with existing floor designs or developing new facilities, the design flexibility of 19 W 4 gratings aids in seamless installations. The plethora of finishes, including painted, powder-coated, and galvanized surfaces, bolster both aesthetic appeal and protective layers against environmental stressors. Comparative Insight 19 W 4 vs. Alternative Grating Sizes When compared to other grating sizes, the 19 W 4 option excels in balancing weight, strength, and cost-effectiveness. For industries weighing multiple options, the grating provides an exceptional equilibrium between initial investment and operational efficacy. Assessments show a noteworthy reduction in maintenance needs compared to tighter mesh alternatives, alongside enhanced light transference and ventilation capabilities. Conclusion Strategic Deployment of 19 W 4 Grating In conclusion, the 19 W 4 grating sizes offer a myriad of benefits that align with the practical needs of modern industry. Their versatility, compliance with standards, customizable nature, and sustainable design underscore their value proposition across diverse sectors. Leveraging their strengths can lead to increased productivity, enhanced safety, and economic efficiency. For facility managers, architects, and engineers, integrating 19 W 4 gratings can signal a forward-thinking approach to infrastructure development, ensuring facilities remain robust, secure, and environmentally conscious.

Authoritativeness Meeting Industry Standards Compliance with industry standards is a critical aspect when selecting grating sizes. The 19 W 4 grating meets ANSI/NAAMM (MBG 531-09) guidelines, ensuring that every piece manufactured under this specification adheres to rigorous quality checks and durability tests. This grating size is renowned for meeting OSHA safety standards, particularly in facilities requiring fall protection measures. My interactions with industry leaders affirm these gratings as a trusted ally in constructing ergonomic and safe industrial spaces. Trustworthiness Proven Performance and Sustainability Beyond performance, the sustainability of 19 W 4 grating sizes is a noteworthy consideration. They are crafted with recyclable materials, aligning with environmental conservation goals. End-users can trust in their longevity and low maintenance cost, factors which contribute significantly to lifecycle cost benefits. The eco-friendliness and reliability of these gratings are consistently verified through user testimonials and project audits, solidifying their position as a credible and preferred choice. Customization and Design Flexibility An often-overlooked advantage of the 19 W 4 grating is its ease of customization. Industries can tailor these gratings to meet specific architectural requirements, including varied widths and lengths, without compromising structural integrity. Whether integrating with existing floor designs or developing new facilities, the design flexibility of 19 W 4 gratings aids in seamless installations. The plethora of finishes, including painted, powder-coated, and galvanized surfaces, bolster both aesthetic appeal and protective layers against environmental stressors. Comparative Insight 19 W 4 vs. Alternative Grating Sizes When compared to other grating sizes, the 19 W 4 option excels in balancing weight, strength, and cost-effectiveness. For industries weighing multiple options, the grating provides an exceptional equilibrium between initial investment and operational efficacy. Assessments show a noteworthy reduction in maintenance needs compared to tighter mesh alternatives, alongside enhanced light transference and ventilation capabilities. Conclusion Strategic Deployment of 19 W 4 Grating In conclusion, the 19 W 4 grating sizes offer a myriad of benefits that align with the practical needs of modern industry. Their versatility, compliance with standards, customizable nature, and sustainable design underscore their value proposition across diverse sectors. Leveraging their strengths can lead to increased productivity, enhanced safety, and economic efficiency. For facility managers, architects, and engineers, integrating 19 W 4 gratings can signal a forward-thinking approach to infrastructure development, ensuring facilities remain robust, secure, and environmentally conscious.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025